Connector for optical cable connection. Optical connectors: purpose, types, characteristics of connectors

Housing optical connector It is made of plastic and has a rectangular shape. The ferrule has a diameter of 2.5 mm and is almost completely covered by the body, which protects it from mechanical damage and dirt. The body color depends on the type of connector polishing: UPC - blue, APC - green. SC multimode (MM) connectors are manufactured gray color. Often, duplex SC connectors are used, in this case 2 connectors are connected to each other using a clip (holder).

LC connector.

The LC optical connector is a smaller copy of the SC connector. Its body is rectangular. The ferrule of the connector has a diameter of 1.25 mm and is made of ceramic. There is a latch on the connector body, the connector is fixed with the help of translational movement. This type of connector is designed for use in high-density mounting. The body color depends on the type of connector polishing: UPC - blue, APC - green. LC multimode (MM) connectors are available in grey. The duplex LC connector consists of two connectors fastened with a clip (holder).

Types of terminated fiber:

Polishing types: PC, UPC, SPC, APC.

Types of terminated fiber: SM, MM.

Fiber sheath diameter: 0.9, 2, 3 mm.

FC connector.

The body of the FC connector is made of plastic and has a rounded shape. The connector is fixed by screwing the movable part of the connector onto the optical adapter. On the front of the connector there is a notch (key) that prevents the connector from turning when it is fixed. The color of the shank depends on the type of polishing. The ferrule of the connector is made of ceramic and has a diameter of 2.5 mm. Compared to LC and SC connectors, it has both positive and negative sides. On the positive side, the FC connector is rigidly fixed to the optical adapter, which makes it resistant to vibrations and gives an undeniable advantage of using it on backbone connections. Of the negative - just a rigid fixation makes it inconvenient during installation, the possibility of circular rotation at the junction of optical fibers negatively affects wear resistance.

Types of terminated fiber:

Polishing types: PC, UPC, SPC, APC.

Types of terminated fiber: SM, MM.

Fiber sheath diameter: 0.9, 2, 3 mm.

ST connector.

The body of the optical connector is made of metal and has a rounded shape. The connector is fixed by means of latches on the rotating frame of the connector. The clamping force is achieved by a spring installed between the body and the movable frame. On the front of the connector there is a notch (key) that prevents the connector from turning when it is fixed. The color of the connector depends on the type of polishing. The ferrule of the connector is made of ceramic and has a diameter of 2.5 mm. If we compare the ST connector with the three previous ones, then we can only answer a couple of its positive aspects - a fairly strong fixation in the optical adapter (strong in terms of not being able to fall out or accidentally pull out) and ease of installation. But there are a lot of negative ones - a ferrule strongly protruding from the body, the possibility of circular rotation, low vibration resistance (since the connector is not rigidly fixed on the optical adapter). At present, this type of connector can be classified as endangered, although it is not yet often found in fiber-optic communication lines.

Types of terminated fiber:

Polishing types: PC, UPC, SPC.

Types of terminated fiber: SM, MM.

Fiber sheath diameter: 0.9, 2, 3 mm.

Optical connectors(ORS) have the same purpose in fiber-optic communication lines (FOCL) as electrical connectors(ER) in electrical lines connections. The only difference is that optical connectors provide optical continuity rather than electrical flow. The first OR appeared simultaneously with optical cables (OC), much later than ER. Due to the complexity of optical flow transmission, the OR range is less diverse, and the design features of the OR and ER have little in common.

optical connector consists of a body, inside of which there is a tip (ferrule) with a precision longitudinal concentric channel. The channel diameter depends on the type of optical fiber - single-mode or multi-mode. For a single-mode fiber, the diameter of the ferrule channel is 125.5-127 µm, for a multimode fiber it is 127-130 µm. The most common outside diameter of ferrules is 2.5 mm, but small form factor optical connectors use 1.25 mm ferrules. Zirconium dioxide is mainly used as the ferrule material.

The purpose of an optical connector is to ensure the passage of light from one element of the FOCL to another with the minimum optical loss at the junction formed by the connector.

The complexity of minimizing losses at the junction is associated primarily with the need to center the cross section of the transmitting and receiving OF in the connector, which must be performed with high accuracy, since the diameter of the OF is small - 50 and 62.5 µm for multimode (MM) and 10 µm for single-mode (SM) fibers. This centering is carried out with the help of a ferrule.

The optical connector must ensure minimal insertion loss (interface parameter) both under normal climatic conditions and under the influence of various external factors. In addition, the stability of the joint parameters during repeated connection-disconnection must be guaranteed.

Basic transmission parameters

The main characteristics of optical connectors include: transmission parameters, long-term stability and resistance to external conditions.

The main transmission parameters of the OR are insertion attenuation and back reflection. These parameters depend mainly on such factors as the transverse displacement of the axes and the angle between them, as well as on the Fresnel reflection of the optical signal at the interface between two optical media.

Optical attenuation has a major impact on the amount of total losses in the optical path. The amount of optical attenuation mainly depends on the transverse deflection of the cores of the spliced optical fibers.

Another important optical characteristic is back reflection. The main source of the reflected signal is the interface between two media, for example, the material of an optical fiber and air. This component of losses can reach significant values. In addition, the back reflection is not constant over time. Under the influence of external influences, it can disrupt the stability of the system. Back reflection creates the most serious problems for narrow-band, high-coherence lasers (such as those used in DWDM systems and in equipment for cable television networks).

While creating optical communication lines there is a problem of the need to splice the optical fibers with each other. Detachable or non-detachable optical connectors are used to perform this task. One-piece connectors are widely used in the creation of long-distance communication lines (for example, public communication networks of a city scale and more). Mechanical connections and splicing of optical fibers are non-detachable. Detachable connectors are applicable in the construction of optical paths of SCS, which are characterized by a small length.

The main functions of the optical connector:

Ensuring the introduction of the fiber into the splicing point with a given bending radius;

Fiber protection from external mechanical and climatic influences;

Fiber fixation in the centering system.

Optical connectors must meet the following technical requirements:

introducing minimal attenuation combined with obtaining high backscatter attenuation;

ensuring long-term stability and reproducibility of parameters;

ease of installation on the cable;

ease of connection and disconnection process;

high mechanical strength with minimal dimensions and weight;

the presence of convex end surfaces at the tips;

preliminary special processing of tips.

Main types of optical connectors:

ST- single connector.

Small size with bayonet lock for locking (disconnect and connect (the nut must be turned a quarter of a turn - 90°). This type of connector is preferably used where vibration protection is not required, such as in an office.) Recommended for use in multimode connections. The mounting technology of these connectors is adhesive or crimp. Not recommended for new installations.

FC- a single connector having a metal or plastic body and fixed with a threaded connection. They are most commonly used with single-mode fibers and have an insertion loss of about 0.4 dB. Resistant to shock and vibration. Recommended for single-mode connections in long-distance radio systems and specialized systems. The threaded connection used in the connectors provides reliable protection against accidental disconnection.

SC- the most popular type of optical connector, made of plastic, with a rectangular cross section. Fixation is carried out by a latch with a lock according to the “push-pull” principle, which ensures protection against accidental mechanical influences. Due to their shape and principle of operation, these connectors can be installed in switchgears with high density installation. The advantages of the SC type connector are the ease and speed of connection due to the absence of rotational movements during its implementation. Also, unlike a single (simplex) connector, a double (duplex) is used, in which two SC connectors are combined into one housing. Installation technology - glue or crimp. The insertion loss of the optical SC connector is 0.4 dB or less.

SMA– a small size connector with a fixing nut that provides a rigid connection. Previously used in communication devices for data transmission in measuring equipment. In addition to LAN and SCS technology, this type of connector is widely used in industrial systems, medical and military equipment. Due to the use of special design measures, the degree of protection of the spliced fibers can be IP-65.

LC- Miniature connectors that are about half the size of conventional SC, FC, ST options, with a tip diameter of 1.25mm instead of 2.5mm. This allows for greater patch panel density and dense rack mounting. The connector is fixed with a clamping mechanism that prevents accidental disconnection.

D4- This type of optical connector is widely used for single-mode fiber. It is similar in many ways to the FC connector, but has a smaller diameter 2.0mm tip. The insertion loss of the D4 connector is about 0.4 dB.

FDDI- The connector is designed as a dual channel, uses two ceramic ferrules and a side latch mechanism. The durable casing protects the tips from accidental damage, and the floating joint ensures a tight, effortless joint. The insertion loss is about 0.3 dB for single-mode fiber and about 0.5 dB for multimode. FDDI is a local area network technology used for packet data transmission at a rate of 100 Mbps in accordance with the ANSI standard.

E-2000 and F-3000 connectors. A special key is required to disconnect the connectors, so the chance of accidental disconnection of the E-2000 connector is reduced to zero. After disconnecting the connector, the hole is closed by special curtains. These connectors are distinguished by a large number of connection cycles - up to 2000.

There are still a large number of types of optical connectors - HDSC, FJ, Mini-MPO, SC-Compact, MU, SCDC, SCQC, Mini-MT, MT-RJ, Optoclip II, VF-45, etc. These connectors have a narrow application purpose and not widely used at present.

Buy electronic components You can contact the office of the Partner company.

Optical connectors are used when terminating optical fibers for their joining with passive or active telecommunication equipment.

There are a large number of specialized optical connectors on the market today. In telecommunications and cable television networks, connectors of the SC, FC, ST types, which have standard sizes and miniature LCs, are most widely used. Optical connectors can connect both one and several fibers.

The optical connector consists of a body, inside which there is a tip (ferrule) with a precision longitudinal concentric channel. The channel diameter depends on which optical fiber will be used - single-mode or multi-mode. For a single-mode fiber, the diameter of the ferrule channel is 125.5-127 µm, for a multimode fiber it is 127-130 µm. The most common ferrule outer diameter is 2.5mm, but small form factor optical connectors use 1.25mm ferrules. The standard ferrule material is zirconium dioxide.

The ferrule is connected to an optical fiber: the fiber without a sheath is inserted into the channel of the tip and fixed, the protruding end of the fiber is cleaved parallel to the surface of the end of the ferrule, the end of the ferrule itself is polished. Next, the ferrule with the fiber is combined with the connector body. After connecting the fiber and ferrule, the assembly is tested for defects (on a microscope or interferometer). For single-mode fiber, the fiber alignment accuracy in the ferrule should be higher than 0.5 µm, the angular deviation should be no more than 5 degrees, and the return loss should be no less than 40 dB.

There are several commonly used types of connectors, each of which requires a different assembly method. But at least two steps of these methods are common to all types.

1) The fiber is fixed in the optical connector with epoxy resin. This process is important in terms of ensuring the reliability of the connection. The epoxy resin prevents the movement of the optical fiber, which allows uniform polishing of the ends of the ferrule and the optical fiber.

2) The end of the ferrule is polished to ensure the tightest connection of the connectors. This is necessary in order to reduce attenuation and back reflection introduced into the line at the connection point of the connectors.

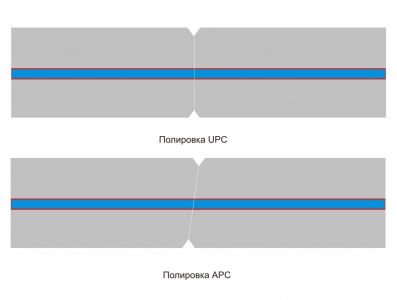

There are several types of polishing

- RS (Physically Contact)

- UPC (Ultra Physically Contact)

- APC (Angled Physically Contact)

- SPS (Super Physically Contact)

In the case of UPC polishing, the plane of the end face of the ferrule is perpendicular to the optical waveguide of the fiber; in the case of APC, it is inclined at an angle of 8°.

In telecommunications, optical connectors with polished UPC, indicated in blue, are used as standard, less often - APC, indicated in green. APC polished optical connectors are not compatible with other types of connectors, they are widely used in cable television networks.

The choice of polishing method depends on the tip material. If the tip material is very hard, such as ceramic, then the tip is generally rounded at the butt end and is referred to as pre-rounded. Soft tip materials such as composite thermoplastics or glass ceramics can be polished flat. These materials are heavily used because they wear out at about the same rate as optical fiber and maintain a high quality physical contact.

The choice of polishing method depends on the tip material. If the tip material is very hard, such as ceramic, then the tip is generally rounded at the butt end and is referred to as pre-rounded. Soft tip materials such as composite thermoplastics or glass ceramics can be polished flat. These materials are heavily used because they wear out at about the same rate as optical fiber and maintain a high quality physical contact.

The end ends of the fiber are rounded so that the light is not reflected directly back to the source (the angle of reflection is equal to the angle of incidence). In the case of a rounded end, the reflection occurs back at an angle and is scattered, and the fibers are in contact with the most protruding points falling on the middle part of the light-carrying core of the fiber. Thus, an air gap is eliminated.

Back reflection can be further reduced by using an APC (Angled Physically Contact). Corner contact reflects light into the cladding of the fiber rather than into the core.

The return loss of the optical connector must be, as already mentioned, at least 40 dB.

Another important characteristic of an optical connector is the number of connection cycles. It is determined by the number of connections / disconnections, from which the performance of the connector will begin to deteriorate. This number, as experience shows, ranges from 200 to 600 compounds. At the end of the life cycle, the connector loss should not increase by more than 0.2 dB.

Connector requirements:

- Low insertion loss

- Small back reflection

- Resistance to external mechanical, climatic and other influences

- High reliability and simplicity of design, slight degradation of parameters after multiple reconnections

Types of optical connectors

ST connectors were developed in the mid 80s. The successful design of these connectors led to the appearance on the market of a large number of their analogues. Currently, ST connectors are widely used in the optical subsystems of local networks. A ceramic tip with a diameter of 2.5 mm, with a convex end surface with a diameter of 2 mm, provides physical contact between the coupled light guides. To protect the end of the fiber from damage during scrolling at the time of installation, a side key is used, which is included in the groove of the socket, the plug on the socket is fixed with a bayonet lock.

ST connectors were developed in the mid 80s. The successful design of these connectors led to the appearance on the market of a large number of their analogues. Currently, ST connectors are widely used in the optical subsystems of local networks. A ceramic tip with a diameter of 2.5 mm, with a convex end surface with a diameter of 2 mm, provides physical contact between the coupled light guides. To protect the end of the fiber from damage during scrolling at the time of installation, a side key is used, which is included in the groove of the socket, the plug on the socket is fixed with a bayonet lock.

ST connectors are simple and reliable in operation, easy to install, relatively inexpensive. However, the simplicity of the design also has negative sides: sensitivity to sharp forces applied to the cable, as well as to significant vibration and shock loads, because the tip is a single unit with the body and shank. This drawback limits the use of this type of connectors on moving objects. ST connector parts are usually made of nickel-plated zinc alloy, less commonly plastic.

When assembling the connectors, the aramid threads of the reinforcing braid of the cable are laid on the surface of the rear part of the case, after which the metal sleeve is pushed and crimped. This design greatly reduces the likelihood of fiber breakage when the connector is pulled out. To further increase the mechanical strength of the connecting cords in the connectors of a number of manufacturers, crimping is provided on the back of the case not only for aramid threads, but also for the outer sheath of the minicable.

The ST connector is currently being replaced by the more advanced FC connector.

This type of connector is widely used for both single mode and multimode fiber. The SC connector belongs to the class of general use connectors and is used both in networks with long sections and in local networks. The device uses a "push-pull" articulation mechanism.

This type of connector is widely used for both single mode and multimode fiber. The SC connector belongs to the class of general use connectors and is used both in networks with long sections and in local networks. The device uses a "push-pull" articulation mechanism.

The basic type SC connector consists of an assembly (plug) containing a ferrule, inserted into the connector housing, centering the ferrule. An optical SC connector can be combined into a module consisting of several connectors. In this case, the module can be used for a duplex connection (one fiber of which is used for transmission in the forward direction and the other in the reverse direction). The connector has a key to prevent misconnection of the fibers.

FC-type connectors are mainly focused on use in single-mode long-distance communication lines, specialized systems and cable television networks. A ceramic tip 2.5 mm in diameter with a convex end surface 2 mm in diameter provides physical contact between the coupled light guides. The tip is manufactured to tight geometric tolerances to ensure low loss and low back reflections. To fix the FC connector on the socket, a union nut with an M8 x 0.75 thread is used. In this design, the spring-loaded tip is not rigidly connected to the body and shank, which complicates and increases the cost of the connector, but this addition pays off with increased reliability.

FC-type connectors are mainly focused on use in single-mode long-distance communication lines, specialized systems and cable television networks. A ceramic tip 2.5 mm in diameter with a convex end surface 2 mm in diameter provides physical contact between the coupled light guides. The tip is manufactured to tight geometric tolerances to ensure low loss and low back reflections. To fix the FC connector on the socket, a union nut with an M8 x 0.75 thread is used. In this design, the spring-loaded tip is not rigidly connected to the body and shank, which complicates and increases the cost of the connector, but this addition pays off with increased reliability.

The insertion loss level of the FC type connector is<0,4 дБ. Они имеют средства для настройки. Ключ настройки позволяет настраивать уровень вносимых потерь до нескольких десятых дБ. После того, как позиция минимальных потерь найдена, ключ может быть зафиксирован.

FC type connectors are resistant to vibrations and shocks, which allows them to be used on appropriate networks, for example, directly on mobile objects, as well as on structures located near railways.

Miniature LC connectors are about half the size of regular SC, FC, ST connectors with a 1.25 mm tip diameter instead of the standard 2.5 mm. This allows for greater patch panel density and dense rack mounting.

Miniature LC connectors are about half the size of regular SC, FC, ST connectors with a 1.25 mm tip diameter instead of the standard 2.5 mm. This allows for greater patch panel density and dense rack mounting.

The connector is fixed with a clamping mechanism that prevents accidental disconnection.

D4 connector

This type of optical connector is especially widely used for single-mode fiber. It is similar in many respects to the FC connector, but has a smaller diameter tip - 2.0 mm.

FDDI connector

The FDDI connector is designed as a dual channel connector, using two ceramic ferrules and a side latch mechanism. The robust casing protects the tips from accidental damage, while the floating joint ensures a tight, effortless joint. The insertion loss is about 0.3 dB for single-mode fiber and about 0.5 dB for multimode. FDDI is a local area network technology used for packet data transmission at a rate of 100 Mbps in accordance with the ANSI standard.

Optical connector E-2000 and F-3000

![]() E-2000 connectors are a rather complex design. A special key is required to disconnect the connector, so there is zero chance of accidental disconnection of the E-2000 connector. After disconnecting the connector, the hole is closed by special curtains. These connectors are distinguished by a large number of connection cycles - up to 2000.

E-2000 connectors are a rather complex design. A special key is required to disconnect the connector, so there is zero chance of accidental disconnection of the E-2000 connector. After disconnecting the connector, the hole is closed by special curtains. These connectors are distinguished by a large number of connection cycles - up to 2000.

F-3000 optical connectors are an improved version of the E-2000 connector. The difference lies in the diameter of the ferrule - 1.25 mm (in the F-3000) and in the material of the shutters, in the F-3000 they are metal.

There are many more types of optical connectors - HDSC, FJ, SC-Compact, MU, SCDC, SCQC, Mini-MT, MT-RJ, Mini-MPO, Optoclip II, VF-45 and others. These connectors have a narrow application purpose and are not currently widely used.

Over the past time, domestic and world manufacturers have created many types of optical connectors, as well as special pass-through adapters used for their reliable connection. Among them, only 4 types of connectors have gained the most popularity: LC, ST, FC and SC. Other connectors are used extremely rarely or are no longer produced. The popularity of individual types of connectors depends on the specific industry in which they are used.

Main types of optical connectors

ST optical connector

Features a metal bayonet design. And the diameter of its ceramic tip is 2.5 mm. Previously, this connector was widely used in networks with multimode optical fibers. Now it is not recommended to use it. Compared with other types, it lacks the ability to create a special duplex connector, has low reliability, poor stability, and is not compact and simple enough.

FC optical connector

Its design is similar to the previous one. The diameter of its ceramic tip is also 2.5 mm, but instead of a bayonet, a metal threaded connection is used. This connector is widely used today in active type equipment and various measuring instruments. It is durable, excellent resistance to all kinds of vibrations. Often it is used in the main FOCL. You can do the same in our company. At AVS Electronics Optics and Components.

SC optical connector

Widespread due to the convenience of switching and the possibility of creating a special duplex connector. It has not only an outer case, but also an inner one. And the diameter of its ceramic tip is 2.5 mm. As a rule, such a connector is installed in the pass-through adapter easily, without the need for rotation. widely used in SCS, modern networks for the transmission of all kinds of data throughout the city. Optical cable

Optical LC connector

The diameter of the tip of this connector is 1.25 mm, so it must be handled with care. Due to their compact size, these connectors have gained immense popularity in various active equipment, modern passive optical cabinets or high-density shelves.  They easily go into a special pass-through adapter with an ordinary snap. The range includes connectors and as well as many others.

They easily go into a special pass-through adapter with an ordinary snap. The range includes connectors and as well as many others.

Among the wide variety of different connectors in the SCS, the advantage is given to duplex SC or LC type connectors with a key, which can prevent incorrect insertion of the connector into the pass-through adapter, ensure the correct polarity of this optical connection. In the latest active equipment and in all data centers, LC type connectors are most often used, because they are very compact and reliable. You can buy connectors and connectors from AVS Electronics specialists.

Polishing types

The end surface of most modern optical connectors is placed at an angle of 90 degrees, and the end face of their ceramic tip is slightly rounded. They are distinguished by the quality of the polishing performed:

. PC is an ordinary quality acceptable for simple applications in SCS, modern local area networks with a short distance and a maximum speed of 1 Gbps. The reflectivity index is -35 dB.

. SPC - improved quality, characterized by a reflectivity equal to -40 to -45 dB or less. This polishing is typical for all factory-made pigtails.

UPC - the best quality, exclusively machine polished, enhanced quality control is carried out. Its reflectivity is -50 to -55 dB or less. Often these polished cords are used to make high-precision measurements in today's optical systems, the most demanding applications that run at speeds of 10 Gb/s and beyond.

Connectors with angled APC polishing

The mating surface of the connectors, which have angular polishing, is placed at an angle of 82 degrees. The reflectivity index is -65 dB or less.It will give you the best possible performance at the moment and reduce back reflections, but it is not compatible with all base polished connectors. To reduce the risk of incorrect mating, all the bodies of these connectors, their tails, together with the through adapters, are made in a rich green color. Often used in provider lines and in many networks of modern cable television.

Connector colors

All the above mentioned connectors are produced in several versions: for single-mode optical fibers 9/125 µm or for multimode 50/125 µm. Housings with pass-through adapters in simple multimode connectors are available in black or beige. And single-mode connectors, along with adapters, are often blue. All presented and many others are available at AVS Electronics at wholesale prices, high quality.Optical connector, or connector, is a simple, reliable and relatively inexpensive switching design that provides low loss and low return signal levels.

Currently, a huge variety of types of optical connectors have been developed for various purposes.

Docking of two connectors, both of the same type and different ones, is provided by optical adapters. If different types of optical connectors are joined, they are combined in a hybrid optical adapter. It is also possible to install attenuators in some adapters to attenuate the optical signal.

Basic transmission parameters

The main transmission parameters of optical connectors are insertion loss and back reflection. They depend mainly on the following factors: transverse displacement of the axes and the angle between them; Fresnel reflection of an optical signal at the interface between two optical media.

optical attenuation. It is of the greatest importance for assessing the losses introduced by a detachable connection. It has a major impact on the total loss in the optical path. The amount of back attenuation depends mainly on the misalignment (i.e., transverse deflection) of the cores being joined.

Reverse reflection. The main source of the reflected signal is the interface between two media, for example, the material of an optical fiber and air. This component of losses can reach significant values. In addition, the back reflection is not constant in time. Under the influence of external influences, the back reflection can eventually lead to a violation of the stability of the system.

Termination technology

Manufacturers offer various termination technologies, or in other words, mounting optical connectors on optical fiber.

At the initial stage, it was assumed that the technology for creating detachable connections would include technological operations for fixing the fibers to be connected in the plug-blank using a chemical fixative - epoxy glue or its analogues. After fixing, the optical fiber had to be cleaved, then the end face of the connector with the protruding fiber had to be polished until the required shape of the end was achieved.

Then, in order to speed up the installation process, technologies were developed without the use of epoxy glue - they use mechanical fixation of optical fibers with clamps built into the optical connector and thermal fixation with hot melt adhesives. But over time, these technologies lost popularity, probably due to the cold flow of hot melt adhesives under pressure, due to which the fiber inside the connector shifted along the axis over time, which led to a deterioration or loss of physical contact and, consequently, caused an increase in losses and reverse reflections.

At the moment, the most common connectors with a built-in length of fiber in the buffer and secondary coatings. This segment is joined to the fiber of the cable. And despite the presence of two junctions instead of one, such technology has proven itself well in practice. Its main advantage is the absence of a time-consuming and sometimes high-cost technological operation for polishing the end of the connector when terminating the OF. These procedures are carried out in stationary conditions at the manufacturer. With this approach, the manufacturer can almost endlessly improve the quality of polishing the ends of the spliced fibers, as well as use new technologies aimed at reducing losses and improving the parameters of optical connectors, while the buyer does not need to purchase increasingly sophisticated (and therefore expensive) equipment for final preparation. connectors to work.

Ensuring Optical Contact

Technologically, it is difficult to achieve absolutely perpendicular ends with ideal contact surfaces during fiber polishing. To minimize the reflected signal, it is necessary to ensure the absence of an air gap between the cores of the connected optical fibers. To this end, the ends of the joined fibers are polished in such a way that spherical surfaces are obtained. During docking, the longitudinal clamping of the fibers is set, and this leads to elastic deformation of the ends of the fibers and optical contact in the region of the cores of the connected optical fibers, at which the air gap between them becomes minimal.

For more information about connector polishing classes, see .

Main types of connectors

in connectors type FC Due to the ceramic tip with a diameter of 2.5 mm, which has a convex end surface with a diameter of 2 mm, physical contact of the joined light guides is ensured. The manufacture of this tip in strict geometric parameters guarantees low losses and a minimum of back reflections.

The FC connector is fixed on the socket with a union nut. In this design, there is no rigid connection of the spring-loaded tip with the body and shank, and therefore the connector becomes more complicated and more expensive, but such an addition at the same time pays off with an increase in reliability.

Since connectors of this type are resistant to vibrations and shocks, they can be used on appropriate networks: on mobile objects, structures near railways, etc.

in connectors type ST The physical contact of the coupled light guides is ensured by a ceramic tip 2.5 mm in diameter, which has a convex end surface 2 mm in diameter. In order to protect against damage to the end of the OF when scrolling at the time of installation, a side key is used, which is included in the groove of the socket; the plug is fixed on the socket with a bayonet lock.

in connectors type ST The physical contact of the coupled light guides is ensured by a ceramic tip 2.5 mm in diameter, which has a convex end surface 2 mm in diameter. In order to protect against damage to the end of the OF when scrolling at the time of installation, a side key is used, which is included in the groove of the socket; the plug is fixed on the socket with a bayonet lock.

These connectors are characterized by simplicity and reliability in operation, ease of installation and relatively low price. However, there are also negative sides: these connectors are sensitive to sharp forces applied to the cable and to significant shock and vibration loads, since the tip is a single unit with the body and shank. Due to this disadvantage, the use of such connectors on moving objects is limited. Currently, this type of connectors is widely used in the optical subsystems of local networks.

To eliminate such a disadvantage of FC and ST connectors as the need for a rotational movement when connecting to an adapter, a connector was developed type SC. Its body is rectangular in cross section. There is no rigid connection of the tip with the body and shank.

To eliminate such a disadvantage of FC and ST connectors as the need for a rotational movement when connecting to an adapter, a connector was developed type SC. Its body is rectangular in cross section. There is no rigid connection of the tip with the body and shank.

Connecting and disconnecting this connector is done linearly (push-pull), so that the tips of the connectors are protected from scrolling relative to each other when fixed in the adapter. The opening of the locking mechanism occurs only when the connector is pulled out by the body. Disadvantages of SC connectors: higher price and lower mechanical strength compared to FC and ST connectors. SC type connectors are used to a limited extent on moving objects.

The standard 2.5 mm ceramic core protrudes far beyond the case. The plastic case is equipped with a key that prevents the core from rotating around its axis when screwed into the adapter. Application of connectors DIN type: in test equipment, as well as equipment for telecommunications.

The standard 2.5 mm ceramic core protrudes far beyond the case. The plastic case is equipped with a key that prevents the core from rotating around its axis when screwed into the adapter. Application of connectors DIN type: in test equipment, as well as equipment for telecommunications.

Design features: the key protrudes beyond the metal body (non-technological design), ceramic core of non-standard diameter - 2 mm. Fixing the connectors on the socket is carried out using a union nut.

- E-2000

in connectors type E-2000 one of the most complex designs. Connecting and disconnecting such a connector is done linearly (push-pull). The opening of the locking mechanism occurs only when the connector is pulled out by the body using a special key insert. It is almost impossible to accidentally turn off such a connector without a key: a load is needed to destroy the latch of its body.

in connectors type E-2000 one of the most complex designs. Connecting and disconnecting such a connector is done linearly (push-pull). The opening of the locking mechanism occurs only when the connector is pulled out by the body using a special key insert. It is almost impossible to accidentally turn off such a connector without a key: a load is needed to destroy the latch of its body.

The tip of the E-2000 type connector is a multilayer ferrule with a diameter of 2.5 mm. The housings of both connectors and adapters are made of durable polymer. The main innovation is plastic shutters: they act as plugs when the adapter is disconnected, and also prevent dust from entering the optical contact plane.

This type of connector has improved optical performance and stable temperature characteristics, as well as high reliability. The square section of the housing allows easy implementation of duplex connectors.

High Density Connectors

Based on the analysis of the advantages and disadvantages of the considered connectors, their new types were created. With similar operating parameters, they should have provided greater space savings to increase the density of mounting on front panels.

The dimensions of the RJ-45 type connector became the basis for the dimensions of the adapters, which made it possible to use common design solutions for the installation of RJ-45 and optical connectors of the developed designs.

Connector design type LC relatively simple: the ceramic core, which has a diameter of 1.25 mm, is not connected to the plastic case. Fixation is made by means of a latch (similar to RJ-45). Combining a pair of connectors into a duplex is easy.

Connector design type LC relatively simple: the ceramic core, which has a diameter of 1.25 mm, is not connected to the plastic case. Fixation is made by means of a latch (similar to RJ-45). Combining a pair of connectors into a duplex is easy.

- MT-RJ

Connectors are being made type MT-RJ exclusively in the form of duplex pairs, and therefore cannot be considered universal. Their production is technologically complex.

The body of the connectors contains a pair of metal guides, in which two optical fibers are pre-installed. The optical fibers of the cable are welded to the pre-installed fibers. The cable is fixed after installation by turning the locking key.

Application: in switches, hubs, routers.

- VF-45

An implementation called SJ is possible.

An implementation called SJ is possible.

Connector connection type VF-45 produced linearly (push-pull). The shank of the connector for ergonomics is inclined at an angle of approximately 45 ° from the plane of the connection of the fibers, in other words, lowered down. This ensures a high mounting density. Ceramic ferrules are replaced by a V-groove, which reduces the cost of manufacturing the connector.

The self-latching shutter, which is equipped with a connector, prevents dust from entering the optical contact surface.

Application: in switches, routers, hubs.

This is approximately half the size of the SC. Due to the reduction in size, the locking mechanism in these connectors may be less reliable.

The tip and centralizer are made of ceramic and have a diameter of 1.25 mm. The body is made of plastic, and the parts are polymer and metal.

The proposed optical connectors can be found in.