Electrical resistance measurement. DC Resistance Measurement - AC Motor Testing

Choice of measurement methoddepends on expected measured resistance values and required accuracy. Main DC resistance measurement methods are indirect, direct evaluation method and bridge.

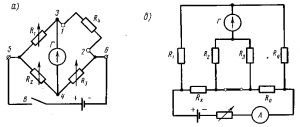

Figure 1. Schemes of probes for measuring large (a) and small (b) resistances

Figure 2. Schemes for measuring large (a) and small (b) resistances ammeter-voltmeter method In the main circuits of the indirect method, voltage and current meters are used.

Figure 1, a shows a circuit suitable for measuring resistances of the same order with the input resistance Rv of a voltmeter Rn. Having measured the voltage U0 with a short-circuited Rx, the resistance Rx is determined by the formula Rx \u003d R and (U0 / Ux-1).

Figure 1, a shows a circuit suitable for measuring resistances of the same order with the input resistance Rv of a voltmeter Rn. Having measured the voltage U0 with a short-circuited Rx, the resistance Rx is determined by the formula Rx \u003d R and (U0 / Ux-1).

When measured according to the scheme of Fig. 5.1, b resistors of high resistance are connected in series with the meter, and small - in parallel.

For the first case, Rx = (Ri + Rd)(Ii/Ix-1), where Ii is the current through the meter with Rx short-circuited; for the second case

![]()

where Ii is the current through the meter in the absence of Rx, Rd is an additional resistor.

A more universal method is the ammeter - voltmeter, which makes it possible to measure resistances under certain modes of their operation, which is important when measuring non-linear resistances (see Fig. 2).

For the scheme of Fig. 2, a

![]()

For the scheme of Fig. 2b

Relative methodological measurement error:

Ra and Rv are the resistances of the ammeter and voltmeter.

Rice. 3. Circuits of ohmmeters with serial (a) and parallel (b) measurement circuits

Rice. Fig. 4. Bridge circuits for measuring resistance: a - single bridge, b - double.

From the expressions for the relative error, it can be seen that the circuit in Fig. 2, a provides a smaller error when measuring high resistances, and the circuit in fig. 2, b - when measuring small.

The measurement error using the ammeter-voltmeter method is calculated by the formula

![]()

where gv, ga are the accuracy classes of the voltmeter and ammeter; Up, Ip - measurement limits of the voltmeter and ammeter.

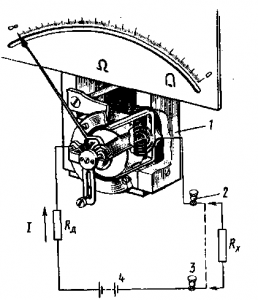

Direct measurement of DC resistance is done with ohmmeters. If the resistance values are more than 1 ohm, ohmmeters with a serial measurement circuit are used, and for measuring low resistances - with a parallel circuit. When using an ohmmeter, in order to compensate for changes in the supply voltage, it is necessary to set the arrow of the device. For a series circuit, the arrow is set to zero when the measured resistance is shunted. (Shunting is performed, as a rule, by a button specially provided in the device). For a parallel circuit, before starting the measurement, the arrow is set to "∞".

To cover the range of small and large resistances, build ohmmeters in parallel-series circuit. In this case, there are two reading scales Rx.

The highest accuracy can be achieved using the bridge measurement method. Medium resistances (10 Ohm - 1 MΩ) are measured using a single bridge, and small ones using a double one.

The measured resistance Rx is included in one of the arms of the bridge, the diagonals of which are connected to the power source and the null indicator, respectively; as the latter, a galvanometer, a microammeter with zero in the middle of the scale, etc. can be used.

Fig 5. Schemes for measuring large (a) and small (b) resistances to alternating current

The equilibrium condition for both bridges is determined by the expression

Shoulders R1 and R3 are usually performed in the form resistance stores (store bridge). R3 is used to set a number of R3/R2 values, usually multiples of 10, and R1 is used to balance the bridge. The reading of the measured resistance is made according to the value set by the handles of the resistance stores. Balancing the bridge can also be done by smoothly changing the ratio of resistors R3 / R2, made in the form of a reochord, at a certain value of R1 (linear bridge).

For repeated measurements of the degree of correspondence of resistances to a certain given value Rн, apply unbalanced bridges. They are balanced at Rx=Rn. On the scale of the indicator, you can determine the deviation of Rx from Rn as a percentage.

For repeated measurements of the degree of correspondence of resistances to a certain given value Rн, apply unbalanced bridges. They are balanced at Rx=Rn. On the scale of the indicator, you can determine the deviation of Rx from Rn as a percentage.

They work on the principle of self-balancing automatic bridges. The voltage that occurs during unbalance at the ends of the diagonal of the bridge, after amplification, acts on the electric motor that stirs the slider of the reochord. When balancing the bridge, the engine stops, and the position of the reochord determines measured resistance value.

Electrical resistance is conditionally divided into small (no more than 1 Ohm), medium (from 1 to 10 5 Ohm), and, accordingly, large (over 10 5 Ohm). They can also be measured in various ways. When measuring small ones, the voltmeter-ammeter method is used, as well as the bridge method. For averages, the methods of a voltmeter-ammeter, bridge (single bridges), compensation and direct evaluation methods (ohmmeters) are applicable. To measure large resistances, they are used, which implement the method of direct evaluation.

Because in this case I A ≈I R relative to R and the equality I V «I R will be satisfied. With an average value of R, the following scheme is recommended:

Since in this case U V ≈U R due to Accordingly, applying Ohm's law, we get:

Due to the presence of internal resistances in the devices, an error occurs, which is the main disadvantage of this method. But when measuring small R, the resistance of the voltmeter will be equal to R V > 100R, and for measuring medium R ammeter R A<100R, то в таком случае суммарная погрешность не будет более 1%.

Direct evaluation method

To implement this method, you must use an ohmmeter, the circuit of which is below:

This device consists of an IM measuring mechanism (the type of mechanism is magnetoelectric), the scale of which is graduated in ohms. There is also a DC power supply U and an additional resistor R d. The measured resistance R X is connected to the output terminals A and B. Accordingly, the current will flow in the circuit:

![]()

Where R D, R I, R X - additional resistor and resistance of the measuring mechanism and, accordingly, the object to be measured. In this case, the angle of deviation of the arrow of the device will be equal to:

![]()

Where S 1 is the sensitivity of the current meter.

If clamps A and B are opened (), then the angle of deviation of the instrument needle will be equal to zero α=0, and if they are shorted (R=0), then the deviation angle will be maximum. Therefore, the ohmmeter has a reverse scale - zero on its right.

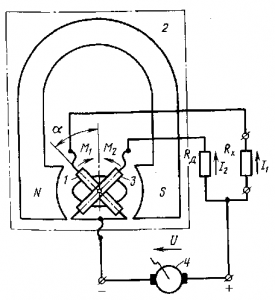

Ohmmeters are quite convenient in practical use, but they have a rather high error (accuracy class 2.5). This is due to the instability of the power supply and the unevenness of the scale. In order to eliminate the cause of the uneven scale in ohmmeters, ratiometric measuring mechanisms began to be used:

Such devices are called megohmmeters. To obtain a power source in megohmmeters, small generators with a voltage of up to 2500 volts and manually driven are used. In electronic megohmmeters, batteries or an external power source connected through a special device power supply can be used as a source. Megohmmeters are used to measure high resistances, such as the insulation resistance of conductors. For measurements above 10 9 Ohm, special electronic devices are used, which are called teraohmmeters.

bridge method

Devices used to implement such a measurement are called measuring bridges. A four-arm or single bridge contains two diagonals and four arms:

The bridge is formed by three resistors, the values of which are known - R 2, R 3, R 4 and, accordingly, the resistance, the value of which must be measured R x. It is necessary to connect a power source to one of the diagonals of the bridge, in this case, the source E 0 connected to terminals a and b, and the other zero indicator NI (terminals c and d), which acts as an indicator of the symmetry of the bridge. When the potentials at points c and d are equal, then the deviation in the NI current flows I NI = 0 and its deviation is also zero. The bridge is in balance. The following relationships will be fulfilled: I 1 = I 2 , I 3 = I 4 , R x I 1 =R 3 I 3 , R 2 I 2 =R 4 I 4 . Taking into account the equality of currents and term-by-term dividing the last two equations, we obtain:

![]()

From this expression, we can select the desired resistance:

The arm R 2 is called the comparison arm, and the ratio arms R 3 and R 4, respectively.

The single bridge method measures only average resistances. It is not recommended to measure small and large resistances with them. The lower measurement limit of the bridge (ohm units) is limited by the influence of the resistance of the wires and contacts that are connected to the ac arm in series with the measurement object R x. The upper limit (10 5 ohms) is limited by the shunt action of leakage currents.

Compensation method

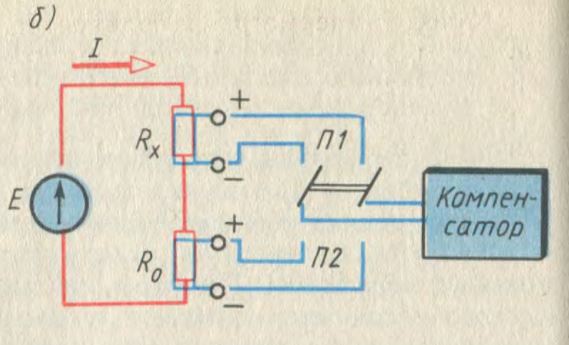

It is used to obtain increased measurement accuracy. Below is a diagram of such an installation:

This circuit includes a DC compensator, a two-position switch (P2 and P1), an exemplary resistor R 0, as well as a power source E and a measured resistor R x. By measuring the voltage drop across each of the resistors at two different switch positions, they determine - U R 0 \u003d R 0 I and U R X \u003d R X I. From these expressions, the following formula can be obtained:

When performing measurements, it is necessary to maintain the current I constant and not allow its value to change in order to ensure measurement accuracy.

Measurement by ammeter and voltmeter method. The resistance of any electrical installation or section of an electrical circuit can be determined using an ammeter and a voltmeter, using Ohm's law. When the devices are turned on according to the scheme of fig. 339, and not only the measured current I x passes through the ammeter, but also the current I v flowing through the voltmeter. So the resistance

R x \u003d U / (I - U / R v) (110)

where R v is the resistance of the voltmeter.

When the devices are turned on according to the scheme of fig. 339, b, the voltmeter will measure not only the voltage drop Ux at a certain resistance, but also the voltage drop in the ammeter winding U A \u003d IR A. Therefore

R x \u003d U / I - R A (111)

where R A is the resistance of the ammeter.

In cases where the resistances of the devices are unknown and, therefore, cannot be taken into account, it is necessary to use the circuit in Fig. 339,a, and when measuring high resistances - with the circuit of fig. 339b. In this case, the measurement error, determined in the first circuit by the current I v , and in the second by the voltage drop UA, will be small compared to the current I x and voltage U x .

Measurement of resistance by electric bridges. The bridge circuit (Fig. 340, a) consists of a power source, a sensitive device (galvanometer G) and four resistors included in the bridge arms: with an unknown resistance R x (R4) and known resistances R1, R2, R3, which can be measured during measurements change. The device is connected to one of the diagonals of the bridge (measuring), and the power source is connected to the other (supplying).

The resistances R1 R2 and R3 can be selected such that when contact B is closed, the readings of the device will be equal to zero (in such a

In which case it is customary to say that the bridge is balanced). However, the unknown resistance

R x \u003d (R 1 / R 2) R 3 (112)

In some bridges, the ratio of the arms R1/R2 is set constant, and the balance of the bridge is achieved only by adjusting the resistance R3. In others, on the contrary, the resistance R3 is constant, and the balance is achieved by selecting the resistances R1 and R2.

Measurement of resistance by a DC bridge is carried out as follows. An unknown resistance R x is connected to terminals 1 and 2 (for example, the winding of an electrical machine or apparatus), a galvanometer is connected to terminals 3 and 4, and a power source (dry galvanic cell or battery) is connected to terminals 5 and 6. Then, by changing the resistances R1, R2 and R3 (which are used as resistance stores, switched by the corresponding contacts), the bridge is balanced, which is determined by the zero reading of the galvanometer (with closed contact B).

There are various designs of DC bridges that do not require calculations, since the unknown resistance R x is read off the scale of the instrument. The resistance boxes mounted in them make it possible to measure resistances from 10 to 100,000 ohms.

When measuring low resistances with conventional bridges, the resistances of the connecting wires and contact connections introduce large errors into the measurement results. To eliminate them, double DC bridges are used (Fig. 340, b). In these bridges, the wires connecting a resistor with a measurable resistance Rx and some reference resistor with a resistance R0 with other bridge resistors, and their contact connections are connected in series with the resistors of the corresponding arms, the resistance of which is set to at least 10 ohms. Therefore, they practically do not affect the measurement results. The wires connecting the resistors with resistances R x and R0 are included in the power circuit and do not affect the equilibrium conditions of the bridge. Therefore, the accuracy of measuring low resistances is quite high. The bridge is made so that when adjusting it, the following conditions are met: R1 = R2 and R3 = R4. In this case

R x \u003d R 0 R 1 / R 4 (113)

Double bridges allow you to measure resistance from 10 to 0.000001 ohms.

If the bridge is not balanced, then the arrow in the galvanometer will deviate from the zero position, since the current of the measuring diagonal at constant values of the resistances R1, R2, R3 and e. d.s. current source will depend only on the change in resistance R x . This allows you to calibrate the galvanometer scale in units of resistance R x or any other units (temperature, pressure, etc.) on which this resistance depends. Therefore, an unbalanced DC bridge is widely used in various devices for measuring non-electric quantities by electrical methods.

Various AC bridges are also used, which make it possible to measure inductance and capacitance with great accuracy.

Measurement with an ohmmeter. The ohmmeter is a milliammeter 1 with a magnetoelectric measuring mechanism and is connected in series with the measured resistance R x (Fig. 341) and an additional resistor R D in the DC circuit. With constant e. d.s. source and resistance of the resistor R D current in the circuit depends only on the resistance R x. This allows you to calibrate the instrument scale directly in ohms. If the output clamps of the device 2 and 3 are short-circuited (see the dashed line), then the current I in the circuit is maximum and the arrow of the device deviates to the right by the largest angle; On the scale, this corresponds to a resistance equal to zero. If the circuit of the device is open, then I \u003d 0 and the arrow is at the beginning of the scale; this position corresponds to a resistance equal to infinity.

The device is powered by a dry galvanic cell 4, which is installed in the device case. The device will give correct readings only if the current source has a constant e. d.s. (the same as with the graduation of the instrument scale). Some ohmmeters have two or more measurement limits, such as 0 to 100 ohms and 0 to 10,000 ohms. Depending on this, a resistor with a measured resistance R x is connected to different terminals.

Measurement of high resistances with megohmmeters. To measure the insulation resistance, megohmmeters of the magnetoelectric system are most often used. As a measuring mechanism, they used a logometer 2 (Fig. 342), the readings of which

hori do not depend on the voltage of the current source supplying the measuring circuits. Coils 1 and 3 of the device are in the magnetic field of a permanent magnet and are connected to a common power source 4.

An additional resistor R d is connected in series with one coil, a resistor with resistance R x is connected to the circuit of the other coil.

The current source is usually a small DC generator 4 called an inductor; the generator armature is rotated by a handle connected to it through a gearbox. Inductors have significant voltages from 250 to 2500 V, due to which large resistances can be measured with a megohmmeter.

When the currents I1 and I2 flowing through the coils interact with the magnetic field of a permanent magnet, two oppositely directed moments M1 and M2 are created, under the influence of which the moving part of the device and the arrow will occupy a certain position. As shown in § 100, the position of the movable

part of the ratiometer depends on the I1/I2 ratio. Therefore, when R x changes, the angle will change? arrow deviation. The megohmmeter scale is calibrated directly in kiloohms or megohms (Fig. 343, a).

To measure the insulation resistance between the wires, it is necessary to disconnect them from the current source (from the network) and connect one wire to terminal L (line) (Fig. 343, b), and the other to terminal 3 (ground). Then, by rotating the handle of the inductor 1 of the megohmmeter, the insulation resistance is determined on the scale of the ratiometer 2. The switch 3 available in the device allows you to change the measurement limits. The voltage of the inductor, and hence the frequency of rotation of its handle, theoretically does not affect the measurement results, but in practice it is recommended to rotate it more or less evenly.

When measuring the insulation resistance between the windings of an electrical machine, they are disconnected from each other and one of them is connected to terminal L, and the other to terminal 3, after which, by rotating the inductor handle, the insulation resistance is determined. When measuring the insulation resistance of the winding relative to the body, it is connected to terminal 3, and the winding is connected to terminal L.

RESISTANCE MEASUREMENT METHODS

Electrical resistance is the main electrical characteristic of a conductor, a value that characterizes the resistance of an electrical circuit or its section to electric current. Also, resistance can be called a part (it is often called a resistor) that provides electrical resistance to current. Electrical resistance is due to the conversion of electrical energy into other forms of energy and is measured in ohms.

Resistance (often denoted by the letter R) is considered, within certain limits, a constant value for a given conductor and can be defined as

Where

R - resistance;

U is the difference in electrical potentials at the ends of the conductor, measured in volts;

I - current flowing between the ends of the conductor under the action of a potential difference, measured in amperes.

For the practical measurement of resistance, many different methods are used, depending on the measurement conditions and the nature of the objects, on the required accuracy and speed of measurements. For example, there are methods for measuring resistance at direct current and at alternating current, measuring high resistances, small and ultra-small resistances, direct and indirect, etc.

The purpose of the work is to identify the main, most common in practice, methods of measuring resistance.

DC resistance measurement

The main methods for measuring DC resistance are the indirect method, the direct evaluation method, and the bridge method. The choice of measurement method depends on the expected value of the measured resistance and the required measurement accuracy. Of the indirect methods, the most universal is the ammeter-voltmeter method.

Ammeter-voltmeter method

This method is based on measuring the current flowing through the measured resistance and the voltage drop across it. Two measurement schemes are used: measurement of high resistances (a) and measurement of low resistances (b). According to the results of measuring current and voltage, the desired resistance is determined.

For circuit (a), the desired resistance and the relative methodological error can be determined by the formulas:

Where Rx is the measured resistance, and Ra is the resistance of the ammeter.

For circuit (b), the required resistance and the relative methodological measurement error are determined by the formulas:

It can be seen from the formula that when calculating the desired resistance according to the approximate formula, an error occurs, because when measuring currents and voltages in the second circuit, the ammeter also takes into account the current that passes through the voltmeter, and in the first circuit, the voltmeter measures voltage in addition to the resistor also on the ammeter .

From the definition of relative methodological errors, it follows that measurement according to scheme (a) provides a smaller error when measuring large resistances, and measurement according to scheme (b) - when measuring low resistances. The measurement error by this method is calculated by the expression:

“The instruments used in the measurement must have an accuracy class of no more than 0.2. The voltmeter is connected directly to the measured resistance. The current during measurement should be such that the readings are read on the second half of the scale. In accordance with this, the shunt is also selected, which is used to be able to measure the current with a class 0.2 device. To avoid heating the resistance and, accordingly, reducing the measurement accuracy, the current in the measurement circuit should not exceed 20% of the nominal value.

The advantage of the circuits of the method of measuring with an ammeter and a voltmeter is that the same current can be passed through the resistor with the measured resistance as in the condition of its operation, which is important when measuring resistances, the values of which depend on the current.

Method of direct assessment.

The direct evaluation method involves measuring the DC resistance with an ohmmeter. An ohmmeter is a direct-reading measuring device for determining electrical active (active resistances are also called ohmic resistances) resistances. Typically, the measurement is made using direct current, however, some electronic ohmmeters can use alternating current. Varieties of ohmmeters: megaohmmeters, teraohmmeters, gigaohmmeters, milliohmmeters, microohmmeters, differing in the ranges of measured resistances.

According to the principle of operation, ohmmeters can be divided into magnetoelectric - with a magnetoelectric meter or magnetoelectric logometer (megaohmmeters) and electronic, which are analog or digital.

“The operation of a magnetoelectric ohmmeter is based on measuring the strength of the current flowing through the measured resistance at a constant voltage of the power source. To measure resistances from hundreds of ohms to several megaohms, the meter and the measured resistance rx are connected in series. In this case, the current I in the meter and the deviation of the moving part of the device a are proportional: I = U/(r0 + rx), where U is the power supply voltage; r0 - meter resistance. For small values of rx (up to several ohms), the meter and rx are connected in parallel.

The ratiometric megaohmmeters are based on a ratiometer, to the shoulders of which are connected in different combinations (depending on the measurement limit) exemplary internal resistors and the measured resistance, the reading of the ratiometer depends on the ratio of these resistances. As a source of high voltage necessary for such measurements, such devices usually use a mechanical inductor - a manually operated electric generator; in some megohmmeters, a semiconductor voltage converter is used instead of an inductor.

The principle of operation of electronic ohmmeters is based on the conversion of the measured resistance into a voltage proportional to it using an operational amplifier. The measured resistor is connected to the feedback circuit (linear scale) or to the input of the amplifier. The digital ohmmeter is a measuring bridge with automatic balancing. Balancing is performed by a digital control device by selecting precision resistors in the bridge arms, after which the measuring information from the control device is fed to the display unit.

“When measuring low resistances, an additional error may occur due to the influence of transient resistance at the connection points. To avoid this, the so-called four-wire connection method is used. The essence of the method is that two pairs of wires are used - a current of a certain strength is supplied to the measured object by one pair, a voltage drop proportional to the current strength and object resistance is applied to the device using the other pair from the object. The wires are connected to the terminals of the measured two-terminal network in such a way that each of the current wires does not directly touch the voltage wire corresponding to it, while it turns out that the transient resistances at the contacts are not included in the measuring circuit.

DC Resistance Bridges

Single bridges are widely used to measure DC resistance. Single bridges are called four-arm bridges powered by a DC source. There are a number of designs of these devices with different characteristics. The error of the bridge depends on the measurement limits and is usually indicated in the bridge passport.

Structurally, bridges are designed in the form of portable devices; they are designed to work with their own or external zero indicator. When measuring low resistances, the measurement result is significantly affected by the resistance of the contacts and connecting wires, summed with the measured resistance. To reduce this influence, special methods are used to connect Rx to the bridge, for which the bridge has four clamps:

When measuring resistances from 10 to 1000000 Ohm, terminals 1 and 2, as well as 3 and 4 are closed with jumpers and the resistor with the measured resistance is connected to terminals 2 and 3. The resistance Rx is measured together with the resistance of the wires and contacts with which it is connected to terminals 2 and 3. When measuring low resistances (those less than 10 ohms), the error introduced by the connecting wires and contacts can be large. You can reduce it by connecting the measured resistor to 4 clamps - 1 and 2, 3 and 4. In this case, the jumpers between points 1 and 2, 3 and 4 are removed, and points A and 4, B and 1 are connected to each other.

In this case, the resistance of the wire from Rx to terminal 2 enters the arm with resistance R, and the resistance of the wire from Rx to terminal 3 enters the arm with resistance R1. The resistances R and R1 are much greater than the resistances of the wires.

When measuring very small resistances, the considered bridge has large errors due to low sensitivity. Increasing the sensitivity by increasing the supply current is limited by the allowable power dissipated in the arms of the bridge. Double bridges are deprived of this shortcoming.

The most common circuit, in which the influence of wires and contacts is minimized, is the double bridge circuit:

The resistances of the bridge arms are indicated by R with the corresponding indices, and the resistances of the connecting wires and contacts by R'1, R'2, etc.

If we accept the resistance of the connecting wires and contacts included in the resistance values indicated by letters with the corresponding indices. When the bridge is in equilibrium, the following conditions are met:

Solving these equations for Rx we find:

It follows from this equation that if the condition R1/R2 = R3/R4 is fulfilled, then the second term of this equation will be equal to zero and the measured resistance Rx can be determined from the equality:

“Double bridges are made with fixed or variable shoulder ratios. The galvanometer at the moment of equilibrium can be closed to a small resistance, therefore, when choosing a galvanometer, devices with a small external critical resistance and possibly greater voltage sensitivity should be preferred. In order to expand measurement limits in industrial instruments, double bridges are combined with single bridges, providing wide measurement limits.

Measurement of very high resistances

There are several methods for measuring high resistances. One of them is the direct deflection method, in which the current flowing through the measured resistance under the influence of a known voltage is directly determined by a sensitive galvanometer connected in series with the resistance. The voltage across the resistance is determined by reading a voltmeter connected in parallel with the resistance. The value of the desired resistance is found on the basis of Ohm's law by dividing the voltage by the amount of current flowing through it. The difference between this method and the ammeter-voltmeter method is only in the replacement of the ammeter with a galvanometer.

This same method underlies commercially available direct-reading megohmmeters. The measuring mechanism in them, as a rule, is of the magnetoelectric type (due to its accuracy, low own consumption and uniformity of the scale). For a certain operating voltage, the device is calibrated directly in units of resistance. Due to the limited sensitivity of megaohmmeters, the operating voltage of megaohmmeters is high (up to 2500 V).

It is very common to measure high resistances using potentiometric circuits. In this case, the measurement limits can be much larger, and the equipment is more reliable and durable than with the direct deflection method. Most industrial megohmmeters and teraohmmeters use the potentiometric method. The measured Rx and the reference Ro resistance form a divider fed from a stable constant voltage source U. The voltage drop across the reference resistance is measured with a voltmeter V with a high input resistance. At a certain voltage value U, each reading u of the voltmeter corresponds to a well-defined value of the measured resistance:

Rx = (U - u)Ro/u,

and the voltmeter is calibrated in units of resistance.

When implementing the potentiometric method of measurement, two problems arise: the manufacture of a stable exemplary resistance and the choice of a high-resistance and sensitive voltmeter. At large limits, resistance measurements Ro can only be non-wire. Potentiometric circuits differ only in the method of measuring the voltage across the reference resistance.

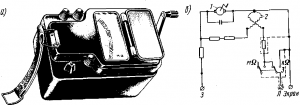

AC resistance measurement

Immittance meter

An immitance meter (or RLC meter) is a radio measuring device designed to determine the parameters of the impedance or conductivity of an electrical circuit. The RLC in the name "RLC meter" is made up of the widely used circuit names of the elements whose parameters this device can measure: R - Resistance, C - Capacitance, L - Inductance.

Among the main methods for measuring the parameters of electrical circuits are bridge methods and the method associated with the use of Ohm's law ratios on alternating current.

The principle of operation of bridge meters of immittance is based on the use of a measuring bridge, for balancing which the device contains sets of exemplary active and reactive resistances. Such devices can only operate at fixed frequencies. The implementation of digital instruments for measuring the parameters of electrical circuits based on bridge methods is accompanied by a noticeable complication of their circuitry and automation of balancing processes.

“Instruments based on the use of Ohm's law ratios are simpler from the point of view of circuit implementation and automated obtaining of the measurement result. The principle of measurement of such immitance meters is based on the analysis of the passage of a test signal (usually sinusoidal) with a given frequency through the circuit being measured, which has a complex resistance. The operating frequency voltage from the internal generator is supplied to the measured object. Voltage, current and phase shift between them are measured in a selected section of the circuit. The measured values are used to calculate the parameters of the circuits.”

measuring line

This is a device for studying the distribution of an electric field along a microwave transmission line. The measuring line is a segment of a coaxial line or waveguide with an indicator moving along it, marking the nodes (antinodes) of the electric field. Using a measuring line, the distribution of the electromagnetic field strength is studied, from which the standing wave coefficient is determined as the ratio of the wave amplitudes in the antinode and the node and the phase of the reflection coefficient by the displacement of the node. Knowing these parameters, the impedance can be found from the impedance circle diagram. Measurements are made using a measuring generator as a signal source. To read the readings, as a rule, a galvanometer or a voltage ratio meter is used. Measuring lines are used at frequencies from hundreds of megahertz to hundreds of gigahertz.

“The line consists of three main units: a segment of the transmission line with a longitudinal narrow slot, a probe head and a carriage with a mechanism for moving the probe head along the line. The probe head is a resonator excited by a probe - a thin wire immersed through a slot into the inner cavity of the waveguide. The immersion depth of the probe in the line is regulated by a special screw located on top of the probe head. A semiconductor detector is placed inside the resonator and is connected to an indicator device. When the probe moves along a line inside which there is an electromagnetic field, an electromotive force is induced in the probe, which is proportional to the field strength in the cross section of the probe location. This e. d.s. excites the resonator, creating electromagnetic oscillations in it. To reduce the distorting effect of the probe on the electromagnetic field in the line and increase the sensitivity of the line, the cavity resonator of the probe head is tuned to resonance with the frequency of electromagnetic oscillations.

A device called an impedance meter is also used to measure the impedance of a circuit. Impedance meters are less sensitive than measuring lines, but they are much smaller, especially in the lower frequency range. The standing wave coefficient, as in the measuring lines, is determined from the ratio of the low-frequency indicator readings at extreme signal values. The impedance of the object under study is found from a circular impedance diagram based on the values of the standing wave coefficient and the phase of the reflection coefficient.

conclusions

There are many different methods for measuring resistance. All of them are different from each other. And in each case it is necessary to choose an individual method for measurement. The most common method of indirect measurement of resistance is the method of measuring through an ammeter and a voltmeter. It is used in a variety of devices for measuring resistance to both direct and alternating current. However, it is not always possible to use ordinary voltmeters and ammeters to measure voltage and current, since they can give an error, for example, when measuring very low resistances due to the presence of resistance in the connecting wires and contacts. Therefore, for a competent measurement of resistance, it is important to choose a method in which the measurement error will be minimal.

METHODS FOR MEASURING CAPACITANCE AND INDUCTANCE

Measuring instruments for direct assessment of the value of the measured capacitance include microfaradmeters, the action of which is based on the dependence of the current or voltage in the alternating current circuit on the value of the measured capacitance included in it. The capacitance value is determined on the scale of the pointer meter.

More widely, balanced AC bridges are used to measure the parameters of capacitors and inductances, which make it possible to obtain a small measurement error (up to 1%). The bridge is powered by generators operating at a fixed frequency of 400-1000 Hz. As indicators, rectifier or electronic millivoltmeters, as well as oscilloscope indicators, are used.

The measurement is made by balancing the bridge as a result of alternating adjustment of its two arms. The readings are taken from the limbs of the handles of those shoulders with which the bridge is balanced.

As an example, consider measuring bridges, which are the basis of the EZ-3 inductance meter (Fig. 1) and the E8-3 capacitance meter (Fig. 2).

Rice. 1. Diagram of a bridge for measuring inductance

Rice. Fig. 2. Bridge circuit for measuring capacitance with small (a) and large (b) losses

When the bridge is balanced (Fig. 1), the inductance of the coil and its quality factor are determined by the formulas Lx = R1R2C2; Qx = wR1C1.

When balancing bridges (Fig. 2), the measured capacitance and loss resistance are determined by the formulas

Measurement of capacitance and inductance using the ammeter-voltmeter method

To measure small capacitances (not more than 0.01 - 0.05 μF) and high-frequency inductors in the range of their operating frequencies, resonant methods are widely used. The resonant circuit usually includes a high-frequency generator, inductively or through a capacitance connected to the measuring LC circuit. As resonance indicators, sensitive high-frequency devices are used that respond to current or voltage.

Using the ammeter-voltmeter method, relatively large capacitances and inductances are measured when the measuring circuit is powered from a low-frequency source of 50 - 1000 Hz. For measurements, you can use the diagrams in Fig. 3.

Figure 3. Schemes for measuring large (a) and small (b) resistances to alternating current

According to the readings of the instruments, the impedance

From these expressions, one can determine

When active losses in a capacitor or inductor can be neglected, the circuit of Fig. 4. In this case

Rice. 4. Schemes for measuring large (a) and small (b) resistances using the ammeter - voltmeter method

Measuring the mutual inductance of two coils

The mutual inductance of two coils can be measured using the ammeter-voltmeter method (Fig. 5) and the series-connected coil method.

Rice. 5. Measurement of mutual inductance using the ammeter-voltmeter method

The value of mutual inductance when measured by the ammeter-voltmeter method

When measuring according to the second method, the inductances of two in series are measured

connected coils with consonant LI and counter LII inclusion of coils. Mutual inductance is calculated by the formula

The device of single measuring bridges of direct current

A single DC bridge consists of three exemplary resistors (usually adjustable) R1, R2, R3 (Fig. 1, a), which are connected in series with the measured resistance Rx in the bridge circuit.

Power is supplied to one of the diagonals of this circuit from the EMF source GB, and a highly sensitive galvanometer RA is connected to the other diagonal through the switch SA1 and the limiting resistance Ro.

Rice. 1. Schemes of single measuring DC bridges: a - general; b - with a smooth change in the ratio of the shoulders and an abrupt change in the comparison shoulder.

The scheme works as follows. When power is applied, currents I1 and I2 pass through the resistors Rx, Rl, R2, R3. These currents will cause voltage drops Uab, Ubc, Uad and Udc in the resistors.

If these voltage drops are different, then the potentials of the points φa, φb and φc will not be the same. Therefore, if the galvanometer is turned on with switch SA1, then a current equal to Ig = (φb - φd) / Ro will pass through it.

The task of the measurer is to balance the bridge, that is, to make the potentials of the points φb and φd the same, in other words, to reduce the galvanometer current to zero.

To do this, they begin to change the resistance of the resistors Rl, R2 and R3 until the galvanometer current becomes zero.

When Ig=0, it can be argued that φb = φd. This is only possible when the voltage drop Uab - Uad and Ubc = Udc.

Substituting in these expressions the values of voltage drops Uad = I2R3, Ubc = I1R1, Udc = I2R2 and Uab = I1Rx, we obtain two equalities: I1Rx = I2R3, I1R1 = I2R2

Dividing the first equality by the second, we get Rх / R1 = R3 / R2 or Rх R2 = R1 R3

The last equality is the condition for balancing a single DC bridge.

It follows from this that the bridge will balance when the products of the resistances of the opposite arms are the same. From here, the measured resistance is determined by the formula Rх = R1R3 / R2

In real single bridges, either the resistance of the resistor R1 (it is called the comparison arm) or the ratio of resistances R3 / R2 is changed.

There are measuring bridges in which only the resistance of the comparison arm changes, and the ratio R3 / R2 remains constant. Conversely, only the ratio R3/R2 changes, while the resistance of the comparison arm remains constant.

The most widespread are measuring bridges, in which the resistance R1 changes smoothly and in jumps, usually a multiple of 10, the ratio R3 / R2 changes (Fig. 1, b), for example, in common measuring bridges P333.

Each measuring bridge is characterized by a limit of resistance measurements from Rmin to Rmax. An important parameter of the bridge is its sensitivity Sm = SgSsh, where Sg=da/dIg is the sensitivity of the galvanometer, Scx=dIg/dR is the sensitivity of the circuit.

Substituting Sg and Scx into Sm, we get Sm= da/ dR.

Sometimes they use the concept of the relative sensitivity of the measuring bridge:

Sm \u003d da / (dR / R).

where dR / R is the relative change in resistance in the measured arm, da is the angle of deviation of the galvanometer needle.

Depending on the design, magazine and linear (rheochord) measuring bridges are distinguished.

In a magazine resistance measuring bridge, the arms are made in the form of plug-in or lever multi-valued measures of electrical resistance (resistance stores), in reochord bridges, the comparison arm is made in the form of a resistance store, and the deviation arms are in the form of a resistor divided by a slider into two adjustable parts.

According to the permissible error, single DC measuring bridges have an accuracy class: 0.02; 0.05; 0.1; 0.2; 1.0; 5.0. The numerical value of the accuracy class corresponds to the largest allowable value of the relative error.

The error of a single DC bridge depends on the degree of commensurability of the resistances of the connecting wires and contacts with the measured resistance. The smaller the measured resistance, the greater the error. Therefore, double DC bridges are used to measure low resistances.

Double DC Bridge Device

The arms of the double (six-arm) measuring bridge are the measured resistance Rx (four-terminal to reduce the effect of transient contact resistances and connected to the network through a special four-terminal device), an exemplary resistor Ro and two pairs of auxiliary resistors Rl, R2, R3, R4.

Rice. 3 Diagram of a double measuring DC bridge

The equilibrium of the bridge is determined by the formula:

Rx \u003d Ro x (R1 / R2) - (r R3 / (r + R3 + R4)) x (R1 / R2 - R4 / R3)

This shows that if the two ratios of the arms R1/R2 and R4/R3 are equal to each other, then the subtrahend is equal to zero.

Despite the fact that the resistances R1 and R4 are set the same by moving the slider D, this is very difficult to achieve due to the spread in the parameters of the resistances R2 and R4.

To reduce the measurement error, the resistance of the jumper connecting the exemplary resistor Ro and the measured resistance Rx should be taken as small as possible. Usually a special calibrated resistor r is attached to the device. Then the subtrahend expression practically becomes equal to zero.

The value of the measured resistance can be determined by the formula: Rх = Ro R1/R2

Dual DC sensing bridges are designed to operate with variable arm ratios only. The sensitivity of the double bridge depends on the sensitivity of the zero pointer, the parameters of the bridge circuit and the value of the operating current. As the operating current increases, the sensitivity increases.

The most widespread are combined DC measuring bridges, designed to work according to single and double bridge circuits.

2

Systematic, progressive and random errors

Errors that do not change over time or are functions of certain parameters that do not change over time are called systematic errors. The main distinguishing feature of systematic errors is that they can be predicted and, due to this, are almost completely eliminated by introducing appropriate corrections.

A particular danger of permanent systematic errors is that their presence is extremely difficult to detect. The only way to detect them is to calibrate the instrument by re-qualification against exemplary measures or signals,

An example of systematic errors of the second type is the majority of additional errors that are time-invariant functions of the influencing quantities that cause them (temperatures, frequencies, voltages, etc.). These errors, due to the constancy of the influence functions in time, can also be predicted and corrected by introducing additional corrective converters that perceive the influencing value and introduce an appropriate correction into the measurement result.

Progressive (or drift) errors are unpredictable errors that change slowly over time. These errors, as a rule, are caused by the aging processes of certain parts of the equipment (discharge of power supplies, aging of resistors, capacitors, deformation of mechanical parts, shrinkage of paper tape in self-recording devices, etc.). A feature of progressive errors is that they can be corrected by introducing a correction only at a given point in time, and then increase again unpredictably. Therefore, unlike systematic errors, which can be corrected by a correction found once for the entire life of the device, progressive errors require continuous repetition of the correction and the more frequent, the smaller their residual value should be. Another feature of progressive errors is that their change in time is a non-stationary random process and therefore, within the framework of a well-developed theory of stationary random processes, they can only be described with reservations.

Random errors are called errors that are unpredictable either in sign or in size (or insufficiently studied) errors. They are determined by a set of reasons that are difficult to analyze. The presence of random errors (in contrast to systematic ones) is easily detected during repeated measurements in the form of a certain scatter in the results obtained. Thus, the main distinguishing feature of random errors is their unpredictability from one sample to another. Therefore, the description of random errors can only be carried out on the basis of probability theory in mathematical statistics.

However, since most of the components of the errors of the means and results of measurements are random errors, the only possible developed way to describe them is to use the provisions of the theory of probability and its further development in relation to the processes of information transmission in the form of information theory, and for processing the obtained experimental data, containing random errors - methods of mathematical statistics. Therefore, it is this group of fundamental sections of mathematics that is the basis for the development of the modern theory of error estimates for means, processes, and measurement results.

Examples of systematic additive errors are errors from an extraneous load on the balance pan, from inaccurate zeroing of the instrument before measurement, from thermo-EMF in DC circuits, etc. To eliminate such errors, many MIs provide a mechanical or electrical device for zeroing (zero corrector).

Examples of random additive errors are the error from the induction of a variable emf at the input of the device, errors from thermal noise, from friction in the supports of the moving part of the measuring mechanism, from unreliable contact when measuring resistance, the error from the influence of the planing threshold of devices with manual or automatic balancing, etc. .

The reasons for the occurrence of multiplicative errors can be:

changing the gain of the amplifier;

measurement of the stiffness of the membrane of the pressure gauge sensor or the spring of the device;

changing the reference voltage in a digital voltmeter, etc.

3

The accuracy class of the device is a generalized characteristic of the device, determined by the limits of permissible (basic and additional) errors, as well as other characteristics that affect the accuracy.

4

Signals coming from message sources (microphone, television camera, telemetry sensor, and others), as a rule, cannot be directly transmitted over a radio or optical frequency band channel. In order to carry out efficient signal transmission in any medium (atmosphere or glass fiber), it is necessary to transfer the spectrum of signals from the low-frequency region to the region of sufficiently high frequencies.

The procedure for transferring the spectrum from low frequencies to high frequencies is called modulation.

5

Кр=l/T T=Kр∙l, where Т is the oscillation period

Kp - sweep factor

l - length

T 8.55cm5 (µs/cm) = 42.75 (µs)

f=1/T , oscillation frequency

T=42.75(µs)=42.75〖10〗^(-6)(s)

f = 1/(42.75∙〖10〗^(-6))= 23391.8 (Hz) = 23.39 (kHz)

BRIEF THEORY

Ohm's law for a homogeneous section of a chain.

If at the ends of a homogeneous section of the circuit there is a potential difference Dj=j 2 -j 1 , then there is an electric current in the circuit. Current strength I, flowing through this section, is proportional to the potential difference DJ at the ends of the section and is inversely proportional to the resistance R this section of the circuit (or this conductor)

Value U = I×R called voltage drop across the conductor and numerically equal to the amount of heat released in the conductor when a unit electric charge passes through it.

For a homogeneous section (i.e., not containing emf), the potential difference at the ends of the section is numerically equal to the voltage drop in this section, i.e. . DJ = U.

If a conventional analog voltmeter (the deviation of the arrow of which is due to the current passing in the frame or coil) is connected to the points 1 and 2 section of the circuit, it will show the potential difference Dj between these points. The potential difference in this case will be equal to the voltage drop U on a voltmeter, i.e.

U = I V R V (2)

where R V- resistance of the voltmeter,

I V is the current flowing through the voltmeter.

conductor resistance.

If the circuit section is a conductor of length l constant cross section S, homogeneous chemical composition, then the resistance R this conductor is determined by the formula:

where r- resistivity of the material.

Resistivity is numerically equal to the resistance of a homogeneous conductor of unit length and unit section. It depends on the chemical composition of the conductor material, its temperature, and is measured in the SI system in Ohm × m. In practice, an off-system unit is often used - Ohm × mm 2 / m.

At room temperature, conductors made of chemically pure metals have the lowest resistivity. The specific resistance of alloys is large, which allows them to be used for the manufacture of resistors with high resistance (rheostats, heating elements, shunts and additional resistances). In table. 1 gives the resistivity values of some materials.

Table 1

Methods for measuring resistance.

The main methods for measuring DC resistance are: indirect method, direct evaluation method and bridge method. The choice of measurement method depends on the expected value of the measured resistance and the required accuracy. The most versatile of the indirect methods is the "ammeter-voltmeter" method, which consists in the practical use of Ohm's law for a homogeneous section of the circuit. Indeed, formulas (1) and (2) imply

those. measuring the potential difference U at the ends of the conductor and the magnitude of the current I flowing through him, you can determine the resistance R conductor.

Another method for measuring resistance is the bridge method, which is covered in another lab. Bridge circuits do not need to measure currents and voltages, so they give more accurate results.

The direct evaluation method involves measuring the DC resistance with an ohmmeter. But measurements with an ohmmeter give significant inaccuracies. For this reason, this method is used for approximate preliminary measurements of resistances and for testing switching circuits.

In this laboratory work, the method of "ammeter-voltmeter" is studied.