Cable marking vvgng. Deciphering the marking of the power cable VVGng (A) -LS

In the modern world, in every house, production shop, public institution, life and work are based on the use of electricity that flows through electric mains - wires and cables. In addition to the main purpose that they perform, the wires must comply with safety requirements in the fire sector. One of these conductors are cables of the brand VVG, VVGng, VVGp, VVGeng, NGTu, NGu (section 2x1, 2x4, 3x2, 3x4, 3x6, 4x4, 4x6, 4x10, 5x10), having a difference from the others, the permissible service life is long.

Decoding VVGng

Now there is a large selection of wires, cables that have a different insulating coating, section. Technical characteristics are determined by the marking applied to the wire. VVGng also has such a marking. What is a VVGng cable?

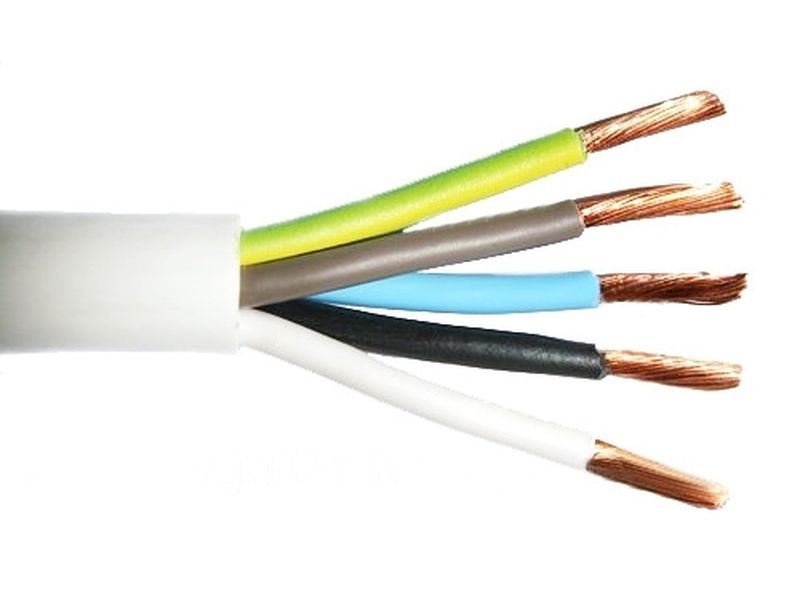

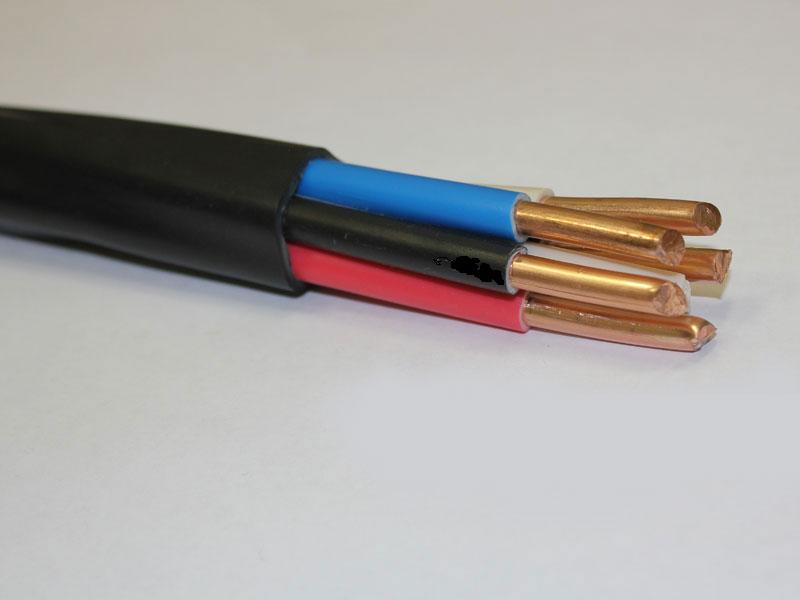

VVGng can have from 1 to 5 wires (cores) in a round or sector shape.

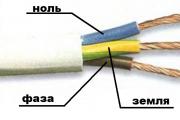

Cores (wires) can be of 1 wire or stranded. The wires are sheathed with insulation, which is colored in whole or in part in accordance with accepted standards. The cores can be copper or aluminum. In the VVGng cable with aluminum conductors, the abbreviation A is additionally placed at the beginning.

Marking is deciphered:

- IN– wire insulation material is made of polyvinyl chloride (thermoplastic polymer, resistant to alkalis, many acids, does not burn, has low frost resistance). There is a polymer insulation made of polyethylene. The designations look like P and Pv.

- Pv- external insulation, the shell is made of polyvinyl chloride. External coatings are distinguished: Shv (there is a protective hose), Shp (made of polyethylene), P (polymer shell).

- G- strands are bare. The wires inside do not have a protective steel braid. If there is armor, then this is indicated by the symbol B.

- NG– does not support combustion at group laying.

VVGng is a cable with external PVC insulation with PVC-coated copper conductors, without armor.

Application and decoding of VVGng a ls

In addition to determining the level of fire safety, cables are tested for striking moments: evaporation of corrosive gases, smoke generation. According to the results of the experiments, additional markings are assigned.

The description of the testing methods is set out in the state standards on Testing electrical and optical cables under flame conditions:

- Category AF/R – GOST R IEC 60332-3-21;

- Category A - GOST R IEC 60332-3-22;

- Category B - GOST R IEC 60332-3-23.

When tested, the cable is exposed to the fire of a gas burner, the test time, installation method and other parameters are different. After the end of the experiment, the length of the burnt area is measured and, if the indicator does not exceed the norm, then the corresponding marking is assigned.

A larger volume of combustible materials does not give a greater spread of combustion. The cable with the highest load in the test, but with the same result, is safer and more durable.

An index can be added to the abbreviation VVGng, about:

- Reduced emission of smoke and gas during thermal exposure - LS.

- Flame retardant with reduced emission of gas and smoke - FRLS.

- The absence of corrosive gaseous chemical elements emitted during smoldering or combustion - HF.

Due to its characteristics, VVGng A LS is used in conditions of high humidity levels, it is used for open, hidden wiring. The purpose for use is to lay a power line in domestic and industrial conditions. Mechanical loads must not be allowed.

Specifications VVGng ls

Physical characteristics, the weight of the cable will depend on the number of cores and the material used. Specifications may vary slightly, depending on the number, cores, cross-section.

The main technical characteristics are:

- Rated (working) mains voltage 660, 1000 V;

- Minimum and maximum temperature during operation -50/+50 °С;

- Humidity of atmospheric air no more than 98%;

- The minimum temperature for carrying out work is up to -15 ° C;

- The maximum possible heating of wires at an overload of 90 °C;

- Maximum continuous temperature up to 70 °С;

- The limiting temperature of the cores, with the condition of not igniting when closed, is 350 ° C;

- A bending radius less than 10 diameters is not allowed;

- The term of work is 30 years.

All of these characteristics are common. When buying and installing, you should be guided by the data of the manufacturer. Often used when laying wiring in rooms is a multi-wire cable VVGng 3 × 1.5.

Use and technical characteristics of the cable VVGng 3x1.5

Used in dry rooms, cable racks. Do not use for underground laying, in conditions of high humidity. When marking, indicate the number of cores, their type and shape, cross-sectional area. After the abbreviation VVGng, numbers are indicated indicating the number of cores and the cross-sectional area.

Then the letter is put:

- O - single wire strands;

- M - multiwire;

- C - sectoral shape of the cores;

- K is round.

VVGng 3 × 1.5 OS - a cable with external PVC insulation, with 3 single-wire copper cores coated with PVC, without armor, each section 1.5 mm², have a sector shape. The number of wires in the cable can be up to 5, therefore, the designations can be 5×1.0, 3×6.0, 2×1.0, 4×6.0. Where the first digit indicates the number of conductive cores, and the second about the cross-sectional area of \u200b\u200beach.

List of technical characteristics of the cable VVGng ls

The cable is multi-core, namely, it has 3 conductive cores covered with PVC insulation. Polyethylene terephthalate film (PET) is used as belt insulation of the core bundle. All elements are placed in a PVC hose that protects against environmental influences.

Characteristics in accordance with the requirements of state standards of the power cable VVGng 3 × 1.5:

- It is operated at a temperature from -50 to +50 °C.

- Bending radius when laying at least 5-82 mm.

- The NG marking indicates the possibility of placement in a group with other conductors, which will not increase the level of fire hazard.

- Work with it is carried out at the lowest possible temperature up to minus 15 ° C.

- It is operated in regions with a cold and temperate climate with a possible placement in the open air (marking UHL1 according to GOST on the climatic design of the product - the impact of external environmental factors on the outer shell).

Heating of the conductive core during short circuit for 4 seconds to +160 °С. In emergency mode for no more than 1000 hours for the entire period of operation, the heating temperature is up to +80 °C. Insulating plastic (polyvinyl chloride or PVC) does not lose its original shape.

The operating temperature of the wire is +70°C.

The voltage in the connected network must be no more than 660 V and a frequency of 50 Hz. With air laying, trench, rated current 21 A and 28 A, respectively. Electrical resistance direct current 12.1 ohm. Physical indicators: approximate outer diameter 11 mm, thickness of the insulating layer from 0.6 mm, sheath from 1.5 mm, cross-sectional area of each copper wire 1.5 mm². Weight 1 km - 93 kg.

With the help of the VVGng 3 × 1.5 cable, laying is possible in air spaces - on flyovers, in gutters of building structures, open indoors and in a closed way.

Methods for laying wire VVGng

The scope of the cable is different. Like any electric main, a VVGng type cable can be laid in an open and closed way. The open method is allowed on the street, on the surfaces of buildings made of non-combustible materials.

Eg:

- Concrete;

- Brick;

- Gypsum;

- Over a plastered wall, etc.

It is also allowed to lay on suspended structures (cable). These structures must be very reliable, since they must exclude any mechanical influence on the cable (sagging, stretching). If mechanical impact on the electric cable is possible, it is necessary to provide additional protection for it, or if the wiring goes along wooden surfaces, then pipes, metal hose, corrugation and other types of protection are used. The hidden method of pulling the cable is most common in residential areas. It is laid in the voids of the room structures, strobes, then covered with plaster on top. With such a laying of the electrical cable, the risk of damaging it is very low, and therefore, additional protection is not needed. Only in buildings made of wood are protective pipes and other materials used to reduce the risk of fire.

To connect any electrical equipment at work or at home, you need a wire corresponding to the expected load section. The most commonly used cable is VVG, the use of which is possible in an open and closed way of laying.

This cable has several types of marking, the decoding of which indicates the version. Consider the main symbols and technical characteristics that the wire of this brand has.

Cable types

It will be useful for novice electricians to find out what varieties the wire of the VVG brand has, and what is the decoding of the marking:

- The standard version of VVG is double PVC insulation, which does not have additional protective characteristics;

- The protective winding of the VVGng wire is made of non-combustible PVC material;

- The use of halogen-free PVC as insulation gives the VVG cable with the additional abbreviation ng-ls such a property as smokeless melting or burning. It is recommended to use in public places where there is a high probability of poisoning people;

- For laying in conditions with a high risk of fire, the use of a cable marked ng-frls is prescribed. This type of electrical wiring is fire resistant, and does not smoke when ignited. Asphyxiating gases are also not emitted.

This type of wire is used for open mounting or in closed channels in places with increased fire safety requirements.

The most commonly used type of wire is VVGng - the technical characteristics and reasonable price make this type of electrical cable the best option in any field. It can be used not only in wooden buildings, but also in wet conditions.

Cable marking designation

Now let's look at what the abbreviation means, which is applied to the VVG cable. Deciphering the symbols makes it easy to determine all the properties and technical characteristics that this wire possesses.

If the conductors of the cable are made of aluminum, the letter (A) is placed in front of all designations. For copper wires, the additional designation does not apply.

The insulation material of conductive conductors has the following designation:

- P - insulation made of polymeric materials;

- B - polyvinyl chloride;

- Pv - material based on polyethylene.

Deciphering the following marking letter allows you to find out what the cable sheath is made of:

- B - PVC outer sheath;

- Shv - a protective sheath in the form of a hose;

- P - the wire has a polymer outer insulation;

- Shp - external insulation made of polyethylene hose.

Also, any wire has a letter designation of the degree of protection:

- B - armored;

- D - there is no additional protection, the cable belongs to the category of flexible products.

Fire safety marking

Separately, the marking indicating the category of fire safety of the cable is considered. Deciphering this abbreviation will allow you to determine which group the wire belongs to and where it can be installed:

- ng - this wire does not support open combustion;

- ng-ls - cable with low smoke emission during the melting of insulating materials;

- ng-hf - when melting the wiring, there is no emission of gases that cause corrosion;

- ng-frls - the wire does not support open combustion, and when melted, it emits a minimum content of smoke and gas;

- ng-frhf - this cable has all the protective properties of previous types of wiring.

Note! All products marked ng are intended for group laying. A wire without such an abbreviation is designed for single laying in closed strobes.

In addition, it should be noted that the VVG cable most often has a round cross-section of conductive cores: it is more convenient to use and suitable for widespread use in everyday life or production. Sometimes there is a cable with additional markings in the form of a small letter "p". This means that the conductors have a flat cross section. As a rule, such conductors are designed for high power and are used in industry.

Main characteristics

Now consider the main technical characteristics that the electrical wire has.

Design

The main criterion for the design features of the cable is the number of cores through which the current passes. Depending on the purpose, these veins can be from two to five. In addition, the cores can be made from one (monolithic) wire or from several thin wires twisted together.

The insulation of each conductor is made in different colors, in accordance with international requirements. If there is a grounding conductor, it is indicated by multi-colored insulation and may have a smaller cross section.

As already noted, the most popular cable with a round cross section. But products are also produced that have a sector (flattened or oval), as well as a flat shape of conductive wires.

Cross section of conductors

The cross section of the cores is 1.5–240 mm 2. Here is the recommended cross section for domestic purposes:

- For the lighting circuit, a 1.5 mm 2 wire is used;

- For connecting sockets - at least 2.5 mm 2;

- With a separate connection of powerful consumers (boilers, electric furnaces), it is recommended to use a VVG cable with a conductor cross section of 4 mm 2.

Note! The weight of the cable depends on the cross-section of the cores, the material of the braid and the degree of armor. The mass of 1 km of wire is taken as a basis and varies from 28.5 kg to 10.25 tons.

Operational and technical characteristics

Consider the main indicators that are inherent in the VVG cable:

- Electric current frequency: 50 Hz;

- Permissible voltage - 220, 660 and 1000V;

- The maximum operating temperature is 70 °C. The insulation is able to withstand short-term (4 seconds) heating up to 250 °C during a short circuit;

- Operating conditions are considered to be temperatures from -50 to +50 ° C, relative humidity - up to 98%;

- The insulation resistance is calculated for an operating temperature of 20 °C and depends on the diameter of the conductors: with a cross section of 1.5 mm2, it is 12 MΩ/km. If the cross section is more than 10 mm 2, the calculated resistance will be 0.005 MΩ / km;

- The service life of the cable is 30 years. The warranty is provided for 5 years, and if the wire is not properly stored, it is reduced to two years.

Properly store the cable on wooden spools indoors. In this case, the coils can be both open and closed. When storing reels under a canopy, they are covered with wooden shields!

Laying methods

There are two ways to lay an electrical wire like VVG: open and hidden.

public method

The VVG cable has technical characteristics that allow its open laying on a non-combustible base (concrete, gypsum, brick and other materials).

Also, the cable is laid in a suspended way: on poles, supports, etc. In this case, to prevent stretching under its own weight, steel wire reinforcement (the so-called wire rod) is used. It is practiced to lay a cable inside a metal or corrugated pipe.

Hidden laying method

This method is used in residential areas. The best option is to install electrical wiring before applying a layer of plaster on the walls. With already plastered surfaces, it is required to punch strobes for laying the wire. With this method, mechanical damage is unlikely.

For concealed wiring in wooden or frame houses, corrugated pipes are used, inside which wiring is placed. This significantly increases the fire safety of electrical wiring and the building as a whole.

underground installation

It is forbidden to lay the VVG cable in the ground without additional protection. Sealed boxes, flyovers, pipes, and so on are used as protective structures.

In conclusion, let's say a few words about the manufacturers that produce these products. Almost every cable production plant produces VVG brand wire: it is in demand. Electricians have no complaints about the products of such manufacturers as Moskabel, Energokabel, Sevkabel. We also note that the products of these particular factories are counterfeited most often, so purchase an electrical wire at trusted outlets.

The VVGng (A) -LS cable is a wire that does not distribute combustion, which allows it to be used not only for transmission, but also for the purpose of redistributing electrical energy. These processes are carried out on stationary equipment, characterized by an electric current frequency of up to fifty hertz and a rated voltage of up to six hundred sixty or a thousand volts. Such a cable is characterized by a very extensive scope in various climatic zones, at an impressive height, in water bodies - almost anywhere, if, of course, its damage is prevented. Such a cable is especially relevant for rooms where there is a significant risk of fire - for example, at industrial facilities working with combustible or hazardous compounds.

The marking explains to us what are the main characteristics of a particular cable. Let's try to decipher it together. VVG is vinyl-vinyl-naked. This means that there are several layers of polyvinyl in the product and there is no special protective layer. If you see a combination of the letters "ng", this indicates that if there is a fire hazard, the cable will not support a fire. The letter "a" in brackets is the type of non-proliferation of combustion in accordance with a certain GOST. This suggests that even if the cables are laid in bundles, they will not spread combustion, while classical VVGs have a similar characteristic only in the case of a single laying. But be careful, if the letter "a" is located in front of the abbreviation, it is designed to inform the user that copper was not used to release the cable. The letters ls, frlsltx, etc. are often added to the marking, but in reality this is a similar cable.

Different types of VVGng (A) -LS cable may differ in their characteristics. So, for example, the allowable current indicator can range from twenty-one amperes to several hundred, it all depends on the type of cable and its location.

VVG (a) cable, also known as VVG (a) power wire, also known as VVGng cable, is a flame retardant wire that is used for the transmission and distribution of electricity, which occurs in stationary installations that have an electric current frequency of 50 Hz and a rated voltage of up to 660 or 1000 V. is exceptionally wide - it is used in any climatic conditions, at high altitude, in water - in fact, anywhere, unless, of course, damage is allowed. Especially often this subtype is used in places where there is an increased risk that a fire will occur - for example, in enterprises working with combustible or explosive components.

Decoding cable VVG (a)

The marking allows us to understand in more detail what a given cable is. Here is its transcript: "VVG" means "vinyl-vinyl-naked", which refers us to the presence of two layers of polyvinyl chloride, as well as the absence of a specialized protective layer. Well, “ng”, if it is used in the marking, means that the cable, in the event of a fire hazard, will not spread combustion. The letter "a", very often placed in brackets, means the category of flame retardance according to. In particular, this means that even when laid in bundles, these cables do not spread combustion, while traditional VVG can boast of this only with a single laying. Do not confuse this letter with the “a” that is placed before the abbreviation and means that the cable is not copper. In this case, it is definitely copper. Often ls, frls, frlsltx, frhf are added to the marking, but in fact this is one cable.

Specifications VVGng (a)

At VVGng A can vary a number of parameters. For example, it can be the form factor of the cores (which can be round, triangular or flat), their number (from 1 to, as a rule, 5), their cross sections (from 1.5 mm 2 to 50 mm 2, and sometimes even more), nominal diameter (directly dependent on the cross-sections), mass (from several tens of kilograms to several tons per kilometer). The allowable current can vary from 21A to several hundred, depending on both the type of cable and its location. As you can see, there are a great many variations of this product, so before you buy a cable, you need to study in detail the description of its specific brand, it is this description that will save you time and nerves in the future. The price, again, varies depending on the complexity and size of the cable. But in comparison with other types of VVG, the cost remains at approximately the same level. But any cost is very much justified, because the cable will serve you in conditions of competent operation for more than thirty years, five of which will, as a rule, be guaranteed.

At VVGng A can vary a number of parameters. For example, it can be the form factor of the cores (which can be round, triangular or flat), their number (from 1 to, as a rule, 5), their cross sections (from 1.5 mm 2 to 50 mm 2, and sometimes even more), nominal diameter (directly dependent on the cross-sections), mass (from several tens of kilograms to several tons per kilometer). The allowable current can vary from 21A to several hundred, depending on both the type of cable and its location. As you can see, there are a great many variations of this product, so before you buy a cable, you need to study in detail the description of its specific brand, it is this description that will save you time and nerves in the future. The price, again, varies depending on the complexity and size of the cable. But in comparison with other types of VVG, the cost remains at approximately the same level. But any cost is very much justified, because the cable will serve you in conditions of competent operation for more than thirty years, five of which will, as a rule, be guaranteed.

Traditional Russian brands of cable and wire products usually have a letter designation and have a transcript.

Cables

VVG and AVVG

The first letter A - means the material of the core. A - aluminum, the absence of the first letter - copper

- IN- the first letter B means the insulation material. B - polyvinyl chloride (PVC);

- IN- the second letter B is the material of the cable sheath. B - PVC;

- G- naked, i.e. there are no additional protective layers (armor, etc.) on top of the shell.

VVG-P

A capital letter P after the main brand means a flat version of the cable.

VVGng(A)-LS and VVGng(A)

ng(A)-LS and ng(A) means performance in terms of fire safety indicators.

- If there is no designation ng - the cable is intended for single laying;

- ng- flame retardant in case of group laying;

- ng-ls- flame retardant with low smoke and gas emission;

- ng-HF- do not spread combustion, do not emit corrosive gaseous products during combustion and smoldering;

- ng-frls- flame retardant, fire resistant, with low smoke and gas emission.

The letter (A) means that the cable has an index of “flame retardant category A.

NYM

The German mark, therefore, is indicated in Latin letters.

- first letter N- Normenleitung - the cable is made according to German standards (VDE);

- second letter Y- Isolierung der Adern aus Polyvinylchlorid - PVC insulation;

- third letter M- Mantelleitung - with a protective sheath.

According to the design of the conductive cores:

- oh- single-wire core;

- pl- multi-wire.

for GOST R 53769-2010:

- O- single-wire core;

- m- stranded core;

- To- round vein;

- With- sector or segment core;

- N- zero core;

- PE- ground wire.

Example: NYM 3x1.5ok (N, PE) - with three conductors with a cross section of 1.5 sq. mm, single-wire round conductors, with a zero conductor and a conductor of grounding.

wires

PVA

- P- the wire;

- IN- PVC insulation;

- WITH- connecting.

SHVVP

- W- cord;

- IN- PVC insulation;

- IN- PVC sheath;

- P- flat execution.