How to make more out of DC. How to make alternating current from direct current?

"Belorussian State University computer science and radio electronics”

Department of Information Security

« ELECTRICAL CONVERTERS »

Inverter– converts direct current into alternating current.

Converter– converter DC voltage to constant, but at a different level (with intermediate conversion of the input voltage to alternating voltage and transformation to the desired level).

The central link is the DC-AC voltage converter.

Various schemes of such devices are used:

Transistor and electronic tubes;

Built on transistors with saturable cores;

Relaxation generators, triggers, multivibrators;

Single-cycle, push-pull and bridge circuits;

Thyristor simple and bridge circuits (in powerful devices).

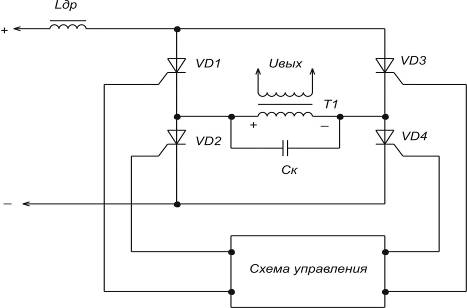

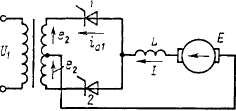

Simple scheme push-pull thyristor inverter

Figure 1 - simple circuit of a push-pull thyristor inverter

From T2 control pulses are sent to the thyristor circuit.

From a constant source, voltage is supplied to the input of the circuit. It goes through

to VD anodes. charges to double the input voltage. If you now apply pulses to VD2, VD1 immediately closes, recharges, all signs in T1 will change to the opposite and current will flow through VD2.As can be seen from the operation of the circuit, on the switching capacitance

at the moment the thyristor closes, a voltage equal to twice the supply voltage is applied, which is a disadvantage for the circuit.It is eliminated by the bridge circuit of the thyristor inverter.

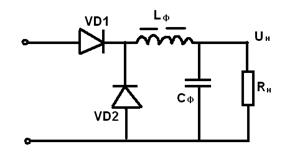

Bridge circuit of a thyristor inverter

Figure 2 - Bridge circuit of a thyristor inverter

The control circuit opens VD1 and VD4 first, and then, when the capacity is charged to

, at this moment, if you open other thyristors, VD1 and VD4 will instantly close.In this circuit, only the voltage of the power source acts on the closed thyristors.

Thyristor rectifiers are effective promising inverters. They are used at significant power and are currently used to replace electrical machine units that convert energy direct current backup batteries in alternating current, in guaranteed power supply devices (UGP) of equipment at communications enterprises.

DC-DC converters

Often when eating electronic devices Power supplies are low-voltage, and significant voltages are required to power the consumption circuits. In this case, they resort to voltage conversion. For this purpose, inverters and converters are used. Electromagnetic transducers, vibration transducers and static transducers are used on semiconductor devices.

Electromagnetic converters produce a sinusoidal voltage, while semiconductor and vibration converters produce a rectangular voltage. Currently, there are static converters with an output voltage that is close to sinusoidal in shape. Disadvantage of the electromagnetic converter: large dimensions and weight. Vibration converters are low-power and unreliable. Therefore, semiconductor converters with small dimensions and weight, high efficiency and operational reliability are most widely used.

The construction of converters based on thyristors and transistors should be related to the magnitude of the supply voltages, the required power, and the nature of the load change.

Transistor voltage converters

They are divided according to the method of excitation into 2 types: self-excited and power amplified converters.

Transistors can be switched on according to the circuit with OE, OK, OB, but switching on with OE is most widely used, since in this case the maximum power gain of the transistors is realized and, even more so, self-excitation conditions are easily achieved.

Converters with self-excitation are made at powerful, up to several tens of watts, using single-cycle and push-pull circuits. The simplest circuit of a single-ended converter is a relaxation oscillator with feedback.

With reverse switch. diode. With direct switching. diode.

When the supply voltage is connected through a resistor, a reference potential is applied to the base of the transistor. The transistor opens and a current flows through the primary winding Wk of the transformer, which causes a magnetic flux in the magnetic circuits of the transistor. The voltage that appears on the winding Wk is transformed in the feedback winding Wb, the polarity of the connection of which is such that it helps to unlock the transistor. When the collector current reaches its maximum value: Ik=Ib*h21e, the increase in magnetic flux will stop, the polarity of the voltages on the transformer windings changes to the opposite and an avalanche-like process of turning off the transistor occurs. The voltage on the secondary winding of the transformer has a rectangular shape.

The polarity of the connection of the rectifier power diode on the secondary winding of the transformer determines the method of transferring energy to the load. The diode opens when the transistor closes, the capacitor is charged, which maintains a constant current in the load.

When the diode is connected directly, the energy transfer from the power source Uп to the load Rн occurs during the time period tu when the transistor and power diode VD1 are open. The energy stored in the throttle is W = 0.5*Lph*In^2*tu. The smoothing filter capacitor Cf is charged by the rectified voltage to Up.

During the pause tp, when the transistor is closed, the current circuit In is closed through the inductor Lf and the blocking diode VD2, as in a pulse stabilizer with serial regulation.

In single-cycle converters, the transformer operates with magnetization, to combat which a core with a charge can be used. However, it is not suitable when using torus. transistor. In our case, a blocking capacitor is used, which during the pause tp is discharged through the winding W1, reversing the magnetization of the core with the discharge current.

Capacity Cbl. It is selected from the condition that at the maximum duty cycle φmax, the duration of the pause tп is not less than a quarter of the period of the oscillatory circuit L, Cbl.

Such a converter with a reverse diode provides decoupling and protection of the output voltage from interference along the input power lines.

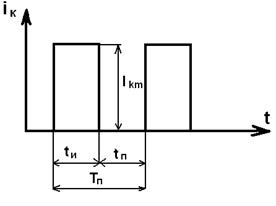

Transistor converters are determined by the following formulas:

Up=Up(Ikm/2In-W1/W2)

tu = Ikm*L1/Up

tп = Ikm*L2/Un*W2

φ = fп*Iкм*L1/Uп = tu/(tu+tп)

Push-pull converters with a step-down transformer have the best weight and size indicators.

Transformers are made on a magnetic core with a rectangular hysteresis loop. Positive OS is also used here. The generator works as follows. When the supply voltage Up is turned on, due to non-identical parameters, one of the transistors, for example VT1, begins to open and its collector current increases. The OS windings Wb are connected so that the EMF induced in them completely opens the transistor VT1 and closes the transistor VT2.

Switching of transistors begins at the moment of saturation of the transistor. As a result, the transf. induced in all windings. The voltages decrease to zero and then change their polarity.

Now a negative voltage is applied to the base of the previously open transistor VT1, and a positive voltage is supplied to the base of the previously closed transistor VT2 and it begins to open. This regenerative process of forming the output voltage front occurs very quickly. Subsequently, the processes in the scheme are repeated.

The switching frequency depends on the value of the supply voltage, the parameters of the transformer and transistors and is calculated by the formula: fп=((Up-Uke us)*10000)/4*B*s*Wк*Sc*Kc.

The switching frequency depends on the value of the supply voltage, the parameters of the transformer and transistors and is calculated by the formula: fп=((Up-Uke us)*10000)/4*B*s*Wк*Sc*Kc. This mode is more economical than when switching due to the limiting collector current and the operation of the converter is more stable.

Such converters are used as master oscillators for power amplifiers and as autonomous low-power power supplies. Main advantages: simplicity of the circuit, as well as insensitivity to short circuits in the load circuit.

The disadvantage of a converter with a saturable core is the presence of collector current surges at the moment of switching transistors, which increases losses in the converter.

The voltage across a closed transistor can reach the value:

Ukem = (2.2: 2.4) Upmax

two voltages are the sum of Up + EMF on the idle winding, in addition, voltage surges during switching are taken into account. To reduce the latter, shunt diodes are sometimes included in the circuit.

When converting high powers, converters using a power amplifier are most widely used. Self-excited converters can be used as a master oscillator. The use of such converters is advisable if it is necessary to ensure a constant frequency and voltage at the output, as well as a constant shape of the alternating voltage curve when the load of the converter changes.

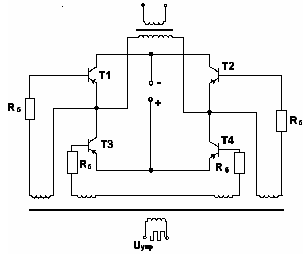

In the case of high input voltage, bridge power amplifiers are used.

Suppose that during the first half-cycle transistors T1, T2 operate simultaneously. In the second T2,T3. The supply voltage is applied to the primary winding of the transistor, its polarity changes every half cycle. The voltage across the closed transistor is equal to the voltage of the power source. The output transistor operates in an unsaturated mode; it is made of a material with a non-rectangular hysteresis loop.

Suppose that during the first half-cycle transistors T1, T2 operate simultaneously. In the second T2,T3. The supply voltage is applied to the primary winding of the transistor, its polarity changes every half cycle. The voltage across the closed transistor is equal to the voltage of the power source. The output transistor operates in an unsaturated mode; it is made of a material with a non-rectangular hysteresis loop. Thyristor converters

Thyristors, unlike transistors, have one-way control. To block thyristors in converter circuits, reactive elements are used, mainly in the form of switching capacitors.

To ensure the blocking of thyristors, it is necessary that the energy of the switching capacitor be sufficient so that during the recharging process the reverse voltage on the thyristors drops sufficiently slowly and has time to ensure the restoration of their blocking properties.

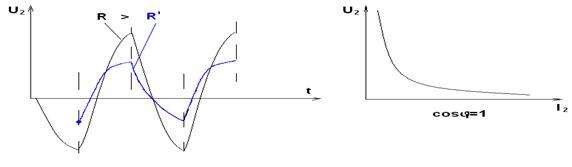

The disadvantage of such an inverter is the strong dependence of the output voltage on the load current.

To reduce the influence of the nature and magnitude of the load on the shape and magnitude of the output voltage, circuits with freewheeling diodes are used, which in turn are necessary to return the reactive energy accumulated in the inductive load and reactive switching elements in the converter power source.

Power supply with transformerless input

A feature of such sources is the use of an input voltage conversion process using high frequency.

The absence of a power transistor at the input and the use of transistors at an increased frequency significantly improves the weight and size characteristics.

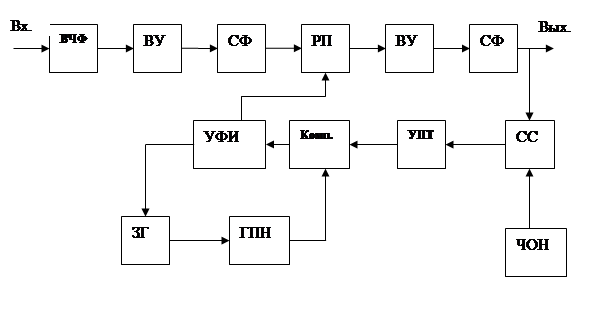

The functional diagram of the IPBV based on an adjustable converter has the following form:

VChF - prevents interference from IPBV from penetrating into the input circuits and vice versa.

VU - rectifying device,

SF – smoothing filter;

RP – adjustable converter;

ZG – synchronizing master oscillator;

GPN – sawtooth voltage generator.

The operation of IPBV with input voltage stabilization using PWM is easy to imagine by examining the voltage diagrams in individual sections of the circuit.

In order to simplify adjustment, the converter is usually built according to a single-cycle circuit, ensuring the recovery of part of the energy accumulated in the reactive elements into the input voltage source. At the output of the converter at voltages of 5 - 10V, a rectifier with a midpoint is installed. In order to reduce the switching time of power transistors, circuits are used at their inputs that provide a significant excess of the blocking voltage relative to the negative one.

LITERATURE

1. Ivanov-Tsyganov A.I. Electrical devices of radio systems: Textbook. - Ed. 3rd, revised and additional-Mn: Higher school, 200

2. Alekseev O.V., Kitaev V.E., Shikhin A.Ya. Electrical devices/Ed. A.Ya. Shikhina: Textbook. – M.: Energoizdat, 200–336 p.

3. Berezin O.K., Kostikov V.G., Shakhnov V.A. power supplies for radio-electronic equipment. – M.: Tri L, 2000. – 400 p.

4. Shustov M.A. Practical circuit design. Power supplies and stabilizers. Book 2. – M.: Altex a, 2002. –191 p.

1.3. Conversion alternating current

to constant and constant to variable

Electricity is generated at power plants by synchronous generators, i.e. alternating current generators, which can be conveniently converted by transformers and transmitted over long distances. Meanwhile, there are a number of technological processes that require direct current: electrolysis, battery charging, etc. Therefore, there is often a need to convert alternating current to direct current and vice versa.

Widespread at the beginning of the 20th century. electrical machine converters (single-armature converters and motor-generator sets) have given way to more compact and silent semiconductor rectifiers. Thanks to high

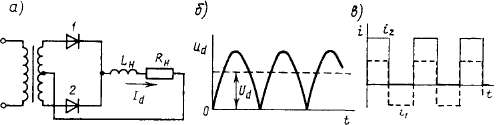

Rice. 1.12. Push-pull single-phase rectifier

Due to the performance indicators and small dimensions of semiconductor rectifiers, there has been a tendency to replace DC generators with synchronous generators that have a semiconductor rectifier at the output. Thus, new classes of machines appeared - transformers and synchronous ones - constantly working with rectifiers. However, the operation of an electric machine on a rectifier has features that must be taken into account when designing these machines and analyzing the processes occurring in them.

AC Conversion V constant produced using semiconductor valves having one-way conductivity. In Fig. 1.12 and 1.13 show the most common rectifier circuits: single-phase (Fig. 1.12, a) and three-phase (Fig. 1.13, a) and voltage and current curves (Fig. 1.12.5. V, rice. 1.13.6, V respectively). Current can pass through semiconductor valves (diodes) only when a positive potential is applied to the anode (in the direction of the apex of the triangle in Fig. 1.12, a), and therefore the voltage across the load is pulsating.

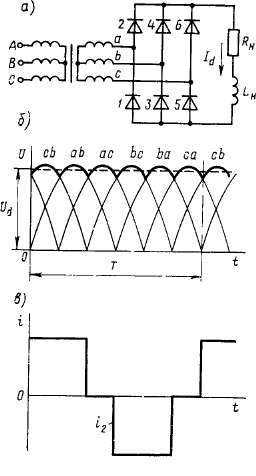

Rice. 1.13. Three-phase bridge rectifier

With single-phase rectification, the voltage ripples across the load are very significant, and the frequency of the alternating component is 2 times higher than the frequency of the alternating current (Fig. 1.12, b). With three-phase bridge rectification, the circuit turns out to be six-cycle and the voltage ripple is small - less than 6% of the constant component (Fig. 1.13, b).

The current in the load circuit is usually smoothed more than the voltage, since the load circuit often contains inductance, which represents a large resistance for the alternating component of the current and a small one for the direct one.

If we consider the current in the load /<* полностью сглаженным, то по обмоткам трансформатора проходит ток, имеющий вид прямоугольников (рис. 1.12,6 и 1.13, V), containing higher harmonics that increase the heating of the windings. In addition, when using rectification circuits with a zero point, there is a constant current component in the windings (Fig. 1.12.6). Because of this, the effective value of the current increases sharply and it is necessary to take measures against the creation of permanent magnetization of the rod. To prevent this phenomenon, for example, in single-phase transformers, either armored structure (Fig. 1.14), or all the windings of the transformer are placed on each rod, dividing them in half.

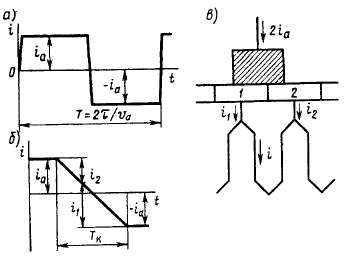

Great influence on the operation of the rectifier (Fig. 1.15, o) current switching has the effect of switching from one valve to another.

Due to the presence of inductances in the current-carrying circuit and the inductance caused by leakage fluxes of the transformer, the current from one valve does not transfer to another instantly, but over the switching period Гк, which corresponds to the switching angle at(Fig. 1.15, b).

For simplicity, we assume that the load current ID perfectly smoothed. Then the sum of the currents through the first and second valves i a\ And iai during the switching process is unchanged:

Rice. 1.14. Schematic drawing of an armor transformer

At the moment of commutation, when the EMF value passes through zero and changes sign, the transformer winding becomes short-circuited and an equation can be written for its circuit

During switching, the voltage across the load is CLg = 0.5(e 2a + +e 2 b) and in a single-phase rectifier is equal to zero (Fig. 1.15, b). Consequently, due to commutation, the rectified voltage decreases and its ripple increases. Since the commutation angle y is greater, the greater the load current Id and inductive reactance x a, To improve the quality of the rectifier, it is desirable that the machine feeding it have a small inductive reactance. In a transformer x a equal to the inductive reactance due to leakage fluxes, and is determined from the experience of a short circuit in a synchronous generator

Where Ha" And x q"- supertransient inductances along the longitudinal and transverse axes, respectively, taking into account the presence of current in the damper winding.

Thus, synchronous generators designed to operate on a rectifier must be designed to operate with non-sinusoidal current and have a damper winding.

The power factor of a generator operating on an unregulated rectifier is

Rice. 1.16. Single-phase inverter circuit

where v«0.9 is the distortion coefficient; >φ «0.5у - current shift angle relative to the first voltage harmonic.

Converting DC to AC produced using inverters that use controlled valves: transistors, thyristors, etc.

The circuit of a single-phase inverter is shown in Fig. 1.16. The inverter valves are switched on alternately every half-cycle so that the direction of the current in the secondary winding of the transformer is opposite to the direction of the EMF in this winding, i.e., so that energy is transferred from the direct current source to the alternating current network.

Inverters have a relatively complex automatic control system, which leads to an increase in their cost and a decrease in reliability compared to uncontrolled rectifiers.

In addition, the inverter may experience a mode through combustion, when the current in the winding is in phase with its EMF. This mode is possible either if there is a malfunction in the control system, or if the switching angle is too large. During through combustion, the current usually increases to an unacceptable value and usually the semiconductor valves fail. The large number of elements in the control system and the possibility of an emergency through-combustion mode make the reliability of inverters significantly lower than that of uncontrolled rectifiers: the mean time between failures is reduced by 50... 100 times.

The idea of powering asynchronous and synchronous motors from inverters is promising. By changing the switching frequency of the valves, you can change the frequency of the voltage at the motor stator terminals and thereby economically (without resistance) regulate the angular speed. This method of speed control is called frequency control. However, the low reliability of systems with inverter-frequency converters prevents their widespread use.

Currently, frequency variable speed control is used only in special conditions where DC motors immersed in liquid cannot operate: ship engines, oil pipelines, ball mill motors, etc.

Rice. 1.17. Design of a DC machine

There are experimental samples with frequency regulation in crane and traction electrical equipment.

A DC machine has a kind of converter-collector, which is a rectifier in generator mode, and a frequency converter in motor mode.

The design of a direct current machine is similar to the design of an inverted synchronous machine, in which the armature winding is located on the rotor and the magnetic poles are stationary. When the armature (rotor) rotates, an EMF is induced in the winding conductors, directed as shown in the cross section in Fig. 1.17, a.

In conductors located on one side of the line of symmetry separating the poles, the emf is always directed in one direction, regardless of the angular velocity. During rotation, some conductors go under the other pole, other conductors take their place, and in space, under a pole of one polarity, the picture is almost motionless, only some conductors are replaced by others. Therefore, it is possible to obtain a practically constant EMF from this part of the winding.

Constant EMF is obtained using sliding contact between the winding and the external electrical circuit.

The conductors are connected in turns with pitch usht, as in AC machines, and then the turns are connected in series one after the other, a closed winding is formed.

In half of the winding (in a two-pole machine), an EMF of one sign is induced, and in the other - of the opposite sign, as shown in the equivalent winding diagram (Fig. 1.17, b). Along the contour of the winding, the EMF in its parts is directed counter and mutually balanced. As a result, when the generator is idling, i.e., in the absence of an external load, no current passes through the armature winding.

The external circuit is connected to the armature through brushes installed on the geometric neutral.

To improve contact, the brushes are made in the form of rectangular graphite bars, and they slide over the surface of the commutator, which is assembled from copper plates isolated from each other.

In large machines the beginning and end of each turn are connected to the commutator plates; in small plate machines

less than the number of turns, and therefore a part of the winding of several turns is soldered between the two plates - a section.

Under load, a current passes through the armature conductors, the direction of which is determined by the direction of the emf.

Due to the fact that the load current is constant, in the turns of the armature winding the current has a shape close to rectangular (Fig. 1.18, a).

When a turn passes from one parallel branch to another, it is short-circuited by a brush for a time called switching period(Fig. 1.18, b)

T K =bJv KOn ,(1.66)

Where b sch- brush width; and Kol - linear speed of a point located on the surface of the collector.

In the simplest case, when the brush is narrower than the collector plate, for the section closed by the brush (Fig. 1.18.0),

Rice. 1.18. Switching current diagrams

Where iiRi=AUi And i 2 R2=AU 2- voltage drop in the brush contact with the first and second collector plates, respectively; Rc- active resistance of the section; L pe3 - the resulting inductance of the section; e k- EMF from an external field. Neglecting iR c due to small size Rc, we get

The resulting basic commutation equation(1.68) coincides with the commutation equation in the rectifier(1.61). The solution to this equation is easy to obtain by assuming that

So that when the first plate leaves the brush, there is no current break, at the moment of time t = TK the current through the first plate should be equal to zero: 11(Gk)=0=21 a -|-ek.sr7 1 k/^res, whence

This condition for sparkless commutation is reduced to the fact that in all modes the commutation angle at was unchanged:

y=*T K =2vJ>JD a v Koll =2b"jD a , (1.71)

Where D a- anchor diameter; v a - linear speed of a point located on the surface of the anchor; b"sh=bshO a/O KO l- brush width reduced to the armature diameter.

To fulfill this condition, the EMF in the EMF commutation zone e k is created by special additional poles, the winding of which is connected in series to the armature circuit, and their magnetic circuit is made unsaturated.

The switching process in rectifiers, inverters and DC machines is similar. In both cases, the process of changing the current during the switching period is determined by the value and shape of the EMF in the short-circuited circuit. Therefore, one cannot liken the collector to a mechanical rectifier, as is sometimes done.

The presence of a collector also introduces its own characteristics: the design of the machine becomes more complicated and operation becomes more expensive. However, these disadvantages of electric machines are compensated by their main advantage: in motor mode, random commutation failures usually lead to slight burnout of the commutator and brushes, and not to emergency mode capsizing, as in inverters.

As a result, the reliability of a DC commutator machine is much higher than the reliability of the “asynchronous motor-frequency converter” system, its efficiency is 3...5% higher, the machine is much cheaper, has smaller dimensions and weight.

These advantages make it necessary to give preference to a DC machine, limiting the use of an asynchronous motor with frequency regulation to the narrow scope of specific devices (motors operating in liquids, etc.).

Unfortunately, power outages in our homes are becoming a tradition. Will the child really have to do his homework by candlelight? Or just an interesting film on TV, I’d like to watch it through. All this can be fixed if you have a car battery. You can assemble a device called a DC-AC converter (or, in Western terminology, a DC-AC converter) to it.

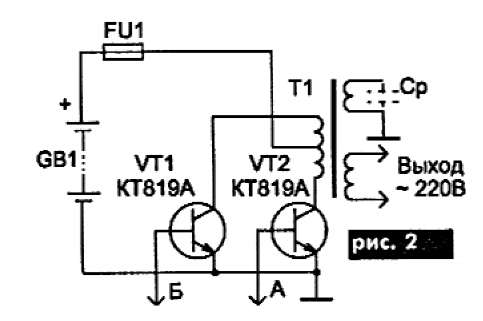

Figures 1 and 2 show two main circuits of such converters. The circuit in Fig. 1 uses four powerful transistors VT1...VT4 operating in switch mode. In one half-cycle of a voltage of 50 Hz, transistors VT1 and VT4 are open. Current from battery GB1 flows through transistor VT1, the primary winding of transformer T1 (from left to right in the diagram) and transistor VT4. In the second half-cycle, transistors VT2 and VT3 are open, the current from battery GB1 goes through transistor VT3, the primary winding of transformer TV1 (from right to left according to the diagram) and transistor VT2. As a result, the current in the winding of transformer TV1 is variable, and in the secondary winding the voltage rises to 220 6. When using a 12-volt battery, the coefficient K = 220/12 = 18.3.

A pulse generator with a frequency of 50 Hz can be built on transistors, logic chips and any other element base. Figure 1 shows a pulse generator based on the KR1006VI1 integrated timer (DA1 chip). From output DA1, pulses with a frequency of 50 Hz pass through two inverters using transistors VT7, VT8. From the first of them, pulses arrive through the current amplifier VT5 to the pair VT2, VT3, from the second - through the current amplifier VT6 to the pair VT1, VT4. If, as VT1...VT4, you use transistors with a high current transfer coefficient ("superbeta"), for example, type KT827B or powerful field-effect transistors, for example, KP912A, then current amplifiers VT5, VT6 can not be installed.

The circuit in Fig. 2 uses only two powerful transistors VT1 and VT2, but the primary winding of the transformer has twice as many turns and a midpoint. The pulse generator in this circuit is the same; the bases of transistors VT1 and VT2 are connected to points A and B of the pulse generator circuit in Fig. 1.

The operating time of the converter is determined by the battery capacity and load power. If we allow the battery to be discharged by 80% (lead batteries allow such discharge), then the expression for the operating time of the converter takes the form:

T(h) = (0.7WU)/P, where W is the battery capacity, Ah; U - rated battery voltage, V; P - load power, W. This expression also takes into account the efficiency of the converter, which is 0.85...0.9.

Then, for example, when using a car battery with a capacity of 55 Ah with a rated voltage of 12 V and a load on an incandescent light bulb with a power of 40 W, the operating time will be 10...12 hours, and with a load on a television receiver with a power of 150 W, 2.5-3 hours.

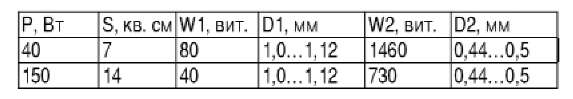

Let us present the data of transformer T1 for two cases: for a maximum load of 40 W and for a maximum load of 150 W.

In the table: S - cross-sectional area of the magnetic circuit; W1, W2 - number of turns of the primary and secondary windings; D1, D2 - diameters of the wires of the primary and secondary windings.

You can use a ready-made power transformer, do not touch the network winding, but wind up the primary winding. In this case, after winding, you need to turn on the mains winding and make sure that the voltage on the primary winding is 12 V.

If you use VT1...VT4 as powerful transistors in the circuit in Fig. 1 or VT1, VT2 in the circuit in Fig. 2 KT819A, then you should remember the following. The maximum operating current of these transistors is 15 A, so if you count on a converter power of over 150 W, then you need to install either transistors with a maximum current of over 15 A (for example, KT879A), or connect two transistors in parallel. With a maximum operating current of 15 A, the power dissipation on each transistor will be approximately 5 W, while without a heatsink the maximum power dissipation is 3 W. Therefore, on these transistors it is necessary to install small radiators in the form of a metal plate with an area of 15-20 cm.

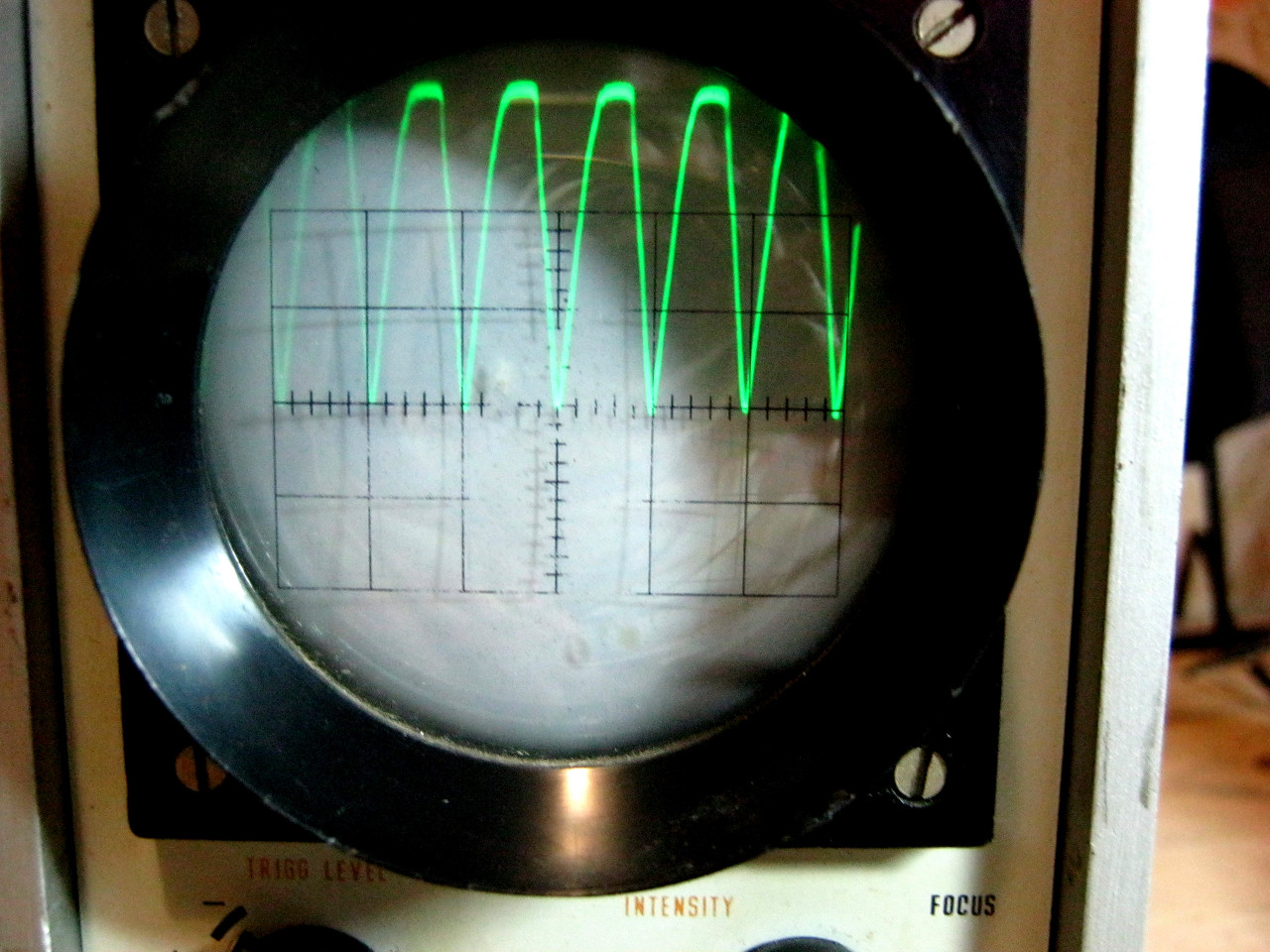

The output voltage of the converter has the form of multipolar pulses with an amplitude of 220 V. This voltage is quite suitable for powering various radio equipment, not to mention light bulbs. However, single-phase electric motors with a voltage of this form do not work well. Therefore, you should not include a vacuum cleaner or tape recorder in such a converter. A way out of the situation can be found by winding an additional winding on the transformer T1 and loading it onto the capacitor Cp (shown with a dotted line in Fig. 2). This capacitor is chosen to be of such a size as to form a circuit tuned to a frequency of 50 Hz. With a converter power of 150 W, the capacitance of such a capacitor can be calculated using the formula C = 0.25 / U2, where U is the voltage generated on the additional winding, for example, at U = 100 V, C = 25 μF. In this case, the capacitor must operate on alternating voltage (you can use metal paper capacitors K42U or similar) and have an operating voltage of at least 2U. Such a circuit absorbs part of the power of the converter. This part of the power depends on the quality factor of the capacitor. Thus, for metal-paper capacitors, the dielectric loss tangent is 0.02...0.05, so the converter efficiency decreases by approximately 2...5%.

To avoid battery failure, it does not hurt to equip the converter with a discharge indicator. A simple diagram of such a signaling device is shown in Fig. 3. Transistor VT1 is a threshold element. While the battery voltage is normal, transistor VT1 is open and the voltage at its collector is below the threshold voltage of the DD1.1 chip, so the signal generator audio frequency Doesn't work on this chip. When the battery voltage drops to a critical value, transistor VT1 is turned off (the shut-off point is set by variable resistor R2), the generator on the DD1 chip starts working and the acoustic element HA1 begins to “squeak”. Instead of a piezoelectric element, a low-power dynamic loudspeaker can be used.

After using the converter, the battery must be charged. For charger you can use the same transformer T1, but the number of turns in the primary winding is not enough, since it is designed for 12 V, but at least 17 V is needed. Therefore, when manufacturing the transformer, an additional winding for the charger should be provided. Naturally, when charging the battery, the converter circuit must be turned off.

V. D. Panchenko, Kiev

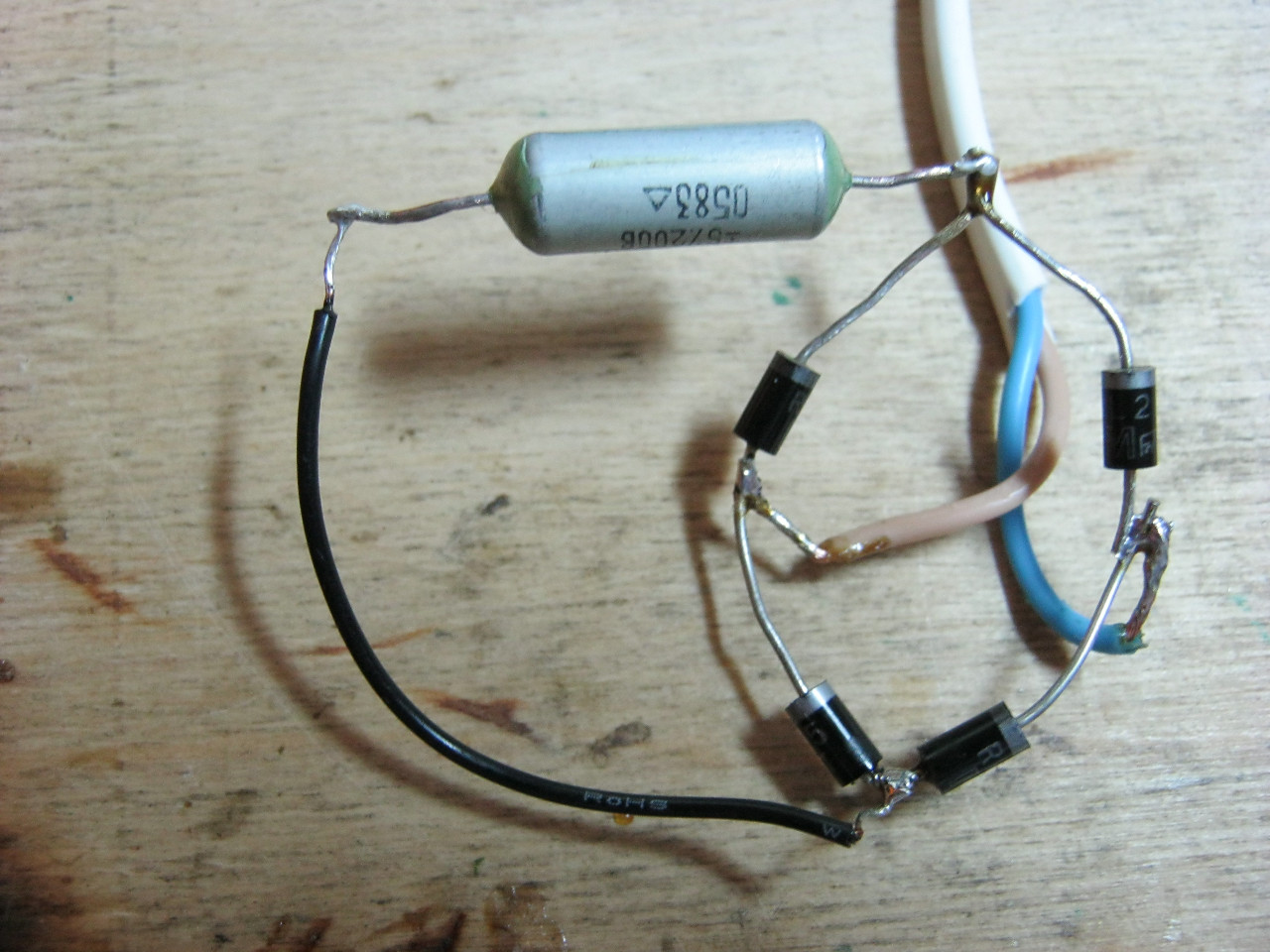

Author: elremont from 08/22/2013In this tutorial, I'm going to talk about silicon diodes, diode bridges, and how to convert AC to DC. This is a symbol for a diode and pictures. The stripe on the end of the diode tells you how to place it in your circuit, but what is a diode?

A diode is a device that allows current to flow in only one direction. This is useful to remember when comparing diodes to water taps, which only allow water to flow in one direction. So if you let AC voltage or current through the diode, the negative voltage will be blocked and you will be left with only the positive half wave. This process is called current rectification...it doesn't just work with sine waves. This will also work with square waves, triangle waves, or any other signals that have a negative half cycle. Wait a minute...

If you zoom in and superimpose the signals on top of each other, you can see that the voltage has decreased! This is because there is no such thing as a perfect diode. All diodes have a forward voltage drop, denoted "Vf". This means that whenever current flows forward through the diode, there will be a voltage drop, which is usually around 0.7 volts. The exact value depends on the temperature, current and type of diode, but for now let's just assume it's 0.7V. So the silicon diode won't even open until there is 0.7V at its terminals and once it opens there will always be a voltage drop of 0.7V across the diode. Test this experimentally to see what I mean: With a negative input voltage, the diode cannot turn on, so you get nothing at the output. 0.3 volts at the input is still not enough to turn on the diode, so again you will get nothing. 0.9 volts at the input is enough to turn on the diode, but due to the voltage drop you only have 0.2V left. And at 10 volts, minus 0.7 volts, you get 9.3 volts.

Sometimes the voltage drop across the diode is a problem... sometimes it's not... For an example I'll show you, at 10 volts peak to peak at the input it's almost imperceptible.

But if I try to rectify a 0.5V current, such as the signal coming from my MP3 player, then the 0.7V drop becomes a problem and it doesn't work. To cope with this problem, one must use advanced technologies such as super diodes. But for now, you don't need to worry about that. No device is 100% efficient, so let's talk about power. Can you predict whether the diode will heat up? Well, the energy loss in a diode is determined by Vf and the current flowing through the diode. For a typical silicon diode with Vf = 0.7 V, when passing one milliamp, only 0.7 mW is lost to heat, so this is not a problem. But at 3A it generates 2.1W of heat, which is quite a lot, so you'll have to use a larger diode or use a diode with a low forward voltage drop, such as a Schottky diode. I'll look at them in another video. By the way, no matter what anyone tells you, when connected in parallel, the diodes will not be able to carry more current.

What happens if one diode closes? The heat that was released on it will be released on other diodes. Old diodes are not ideal, but I don't want to talk about switching high-speed diodes. I use 1N4007 diodes, they are designed for power electronics with low frequency AC 50 - 60 Hz, like in your home.

Now let's see what happens when I increase the frequency. After about 15 kHz the diode becomes useless as it begins to conduct in the reverse direction. This is because it takes a certain amount of time for the diode to switch between an open state, allowing current to flow forward, and a closed state. Different diodes will have different switching speeds. So, if I replace the 1N4007 with a 1N4148, it will work well, up to 100 kHz and even more. To work with radio frequencies, you need to use diodes that switch even faster. So when you're designing something, you have to think about your diode's maximum reverse voltage, forward voltage, current rating, and switching speed. Google will always help you find reference information on diodes. It’s good that in most cases it is not necessary to know the theory of diode operation. So let's use diodes to build something. The most common use of diodes is to convert alternating current to direct current to power various devices you have in your home. I'm going to show you how to build a simple regulated source DC power supply is very similar to this one. I'll start with low current and then I'll show you how to improve the design to handle higher power loads. We start by converting the mains voltage to a lower, safer alternating voltage. I'll show you how to do this in my transformers tutorial. With no load, my transformer gives me a nice clean sine wave of about 39 volts peak to peak at 60 Hz. I installed a 1N4007 diode and measured the voltage before and after the diode, you can see the negative voltage cutoff. Technically I converted AC to DC with just one diode because I removed all the negative voltage. But that's not very good DC, is it? Half the time you have a weird voltage hump and half the time we have nothing at all.

If you need a little more stability to power the payload, we'll add a capacitor to straighten things out. I start with 1uF, but the larger the capacitance the better because you will have more energy storage. This is more like the truth! I now have a perfect 18.7 volt DC source. Whenever you make a constant voltage power supply, the best you can see on the oscilloscope screen is a constant stable voltage. Unfortunately, the only reason why everything looks perfect now is only because I didn't have time to connect the load. The capacitor is charged through the diode, and now there is nothing that can discharge the capacitor. So let's see what happens when I add a 4.7k ohm resistor as a load. Ohm's Law predicts that there should only be 4mA of load (which is very little), but look what happens. You see here that when the input voltage is positive, the diode allows current to flow, thus charging the capacitor. But as soon as the input voltage becomes negative, the diode blocks the reverse flow of current and the only source of energy is a 1 µF capacitor. And as you can see, its energy is quickly consumed even at low load. So what should we do about it? Let's increase the size of our energy reservoir so that it is enough to power us until the next positive half-wave. Let's replace the tiny 1uF capacitor with a large 470uF capacitor and see what happens.

This works very well! We now have a DC power supply that can supply a few milliamps of current which is enough to power some sensors and operational amplifiers. Okay, let's modernize it up a notch. With a ten ohm load, this circuit should draw much more current. Well, that's crap... we're back to the situation where the tension sags in every beat. The average voltage is 8 volts, with a current of about 0.8 amperes, but the magnitude of the voltage ripple is enormous. Imagine if we tried to connect something to these... the voltage would constantly drop so low that it would never stay constant! So even 470 uF as an energy storage device is no longer enough. We can try to solve the problem head-on and add even more capacity.

So let's see how the circuit works with 3400uF. Well... that's better... Now we get an average voltage of about 12.5 volts at a current of about 1.25 A, but we're seeing 5 volts of AC ripple, which is a lot. You can continue to add capacity indefinitely to reduce the amount of sag between cycles. But for loads of a few amps this becomes impractical and expensive. But there is a little trick. If we take four diodes and arrange them in this way, we get a “diode bridge”. Here's how it works: In the first half of the sine wave, the positive wave of the sine wave arrives at the top wire, these two diodes open and allow current to pass. Next, the diodes close, blocking any possible changes in the direction of the current. Now in the second half of the sine wave, where the top wire becomes negative with respect to the bottom wire, the other two diodes open and the other two close. So instead of wasting the bottom half of the AC waveform by cutting it off and never using it, you simply flip it around and redirect it. And at the output you get a direct current with a ripple of 120 Hz instead of 60 Hz.

And just like before, you can process the output signal with capacitors to get a nice smooth voltage. You can buy ready-made bridge rectifiers, but they are easy to build yourself. Here is my bridge rectifier connected to the transformer. I made it from four 1N4007 diodes and I spent about 4 cents on them. Look at how the voltage changes from positive to negative at 60 Hz and now it never goes below zero volts and we get these positive constant voltage half-waves at 120 Hz. This is called full rectification because we are using both waves of AC. Now let's go back to our ten ohm prototyping board and see how the bridge rectifier performs with 470uF of capacitance compared to the single diode we tested earlier.

We now have an average of 11.6 volts instead of the 8 volts we were previously getting from a single diode. And you can see that this is because the bridge rectifier charges the capacitor twice as often because we are using both half-waves of the 60 Hz AC line. Now think about how big of a difference that is, considering those extra diodes only cost me three cents.

The workings of bridge rectifiers can be a little difficult to understand, but since they work so well, everyone uses them. Now let's compare one diode with 3400 uF and a bridge rectifier with 3400 uF. Now we're averaging 13.5 volts instead of 12.5 volts and we only have about one or two volts of ripple. In other words, the combination of a bridge rectifier with a large capacitance can convert a large AC supply current into a large usable DC supply current. Just keep in mind that your diodes and capacitors must be rated for the voltage you are working with.

What we have now is basically the same thing that's inside those cheap little unregulated AC-to-DC power supplies that are used to power radios, clocks, and other home gadgets. We could make a 9 volt version and it could power an older Sega or Nintendo. But I want to emphasize that these are all unregulated power supplies. This means that even if we successfully smooth out the voltage ripple, we will still be faced with the problem of changing the average voltage under load.

Without load it is 18.7 volts. And at 1 amp load you will get 13 volts. For some circuits this will not matter if they are designed to handle a wide range of voltages. But many devices, such as microcontrollers and other digital electronics will require a very stable voltage source, and for this you will need to create what is called an adjustable voltage source. I'll talk about voltage regulators in another video. Now you know what diodes do and how they convert alternating current to direct current.

_

You've probably all wondered: "How to get a constant voltage from an alternating voltage?" Well, it’s time I think I’ll reveal this secret :-), although it can’t be called a secret. In this article I will show you the basics, but what voltage to get is up to you to decide. It turns out that in reality all this is much simpler than it seems.

Let's first clarify what we mean by "constant voltage". As Wikipedia tells us, constant voltage (also known as direct current) is a current whose parameters, properties and direction do not change over time. Direct current flows in only one direction and its frequency is zero. We looked at the DC oscillogram in the article Oscilloscope. Operating Basics. And here is the actual DC voltage oscillogram:

As you remember, horizontally on the chart we have time(X axis), and vertically voltage(Y axis).

To transform a variable single phase voltage one value into a single-phase alternating voltage of a smaller (or larger) value, we use a simple single-phase transformer. And in order to transform into constant pulsating voltage, you and I connected the Diode bridge after the transformer. The output received a constant pulsating voltage. But with such tension, as they say, you can’t change the weather.

But how can we get out of the pulsating constant voltage

get the most real constant voltage?

To do this, we need only one radio component: capacitor. And this is how it should be connected to the diode bridge:

This circuit uses an important property of the Conder: charging and discharging. The whole joke is that the Conder with a small capacity quickly charges and quickly discharges. Therefore, in order to get an almost straight line on the oscillator, we must insert a capacitor of decent capacity.

Let's take a practical look at why we need to install a large-capacity condenser. In the photo below we have three conders. All have different capacities.

Let's look at the first Conder. We measure its nominal value using our LC meter. Its capacity is 25.5 nanoFarads or 0.025 microFarads.

We connect it to the diode bridge according to the diagram above

And we take readings from the Conder with an oscil.

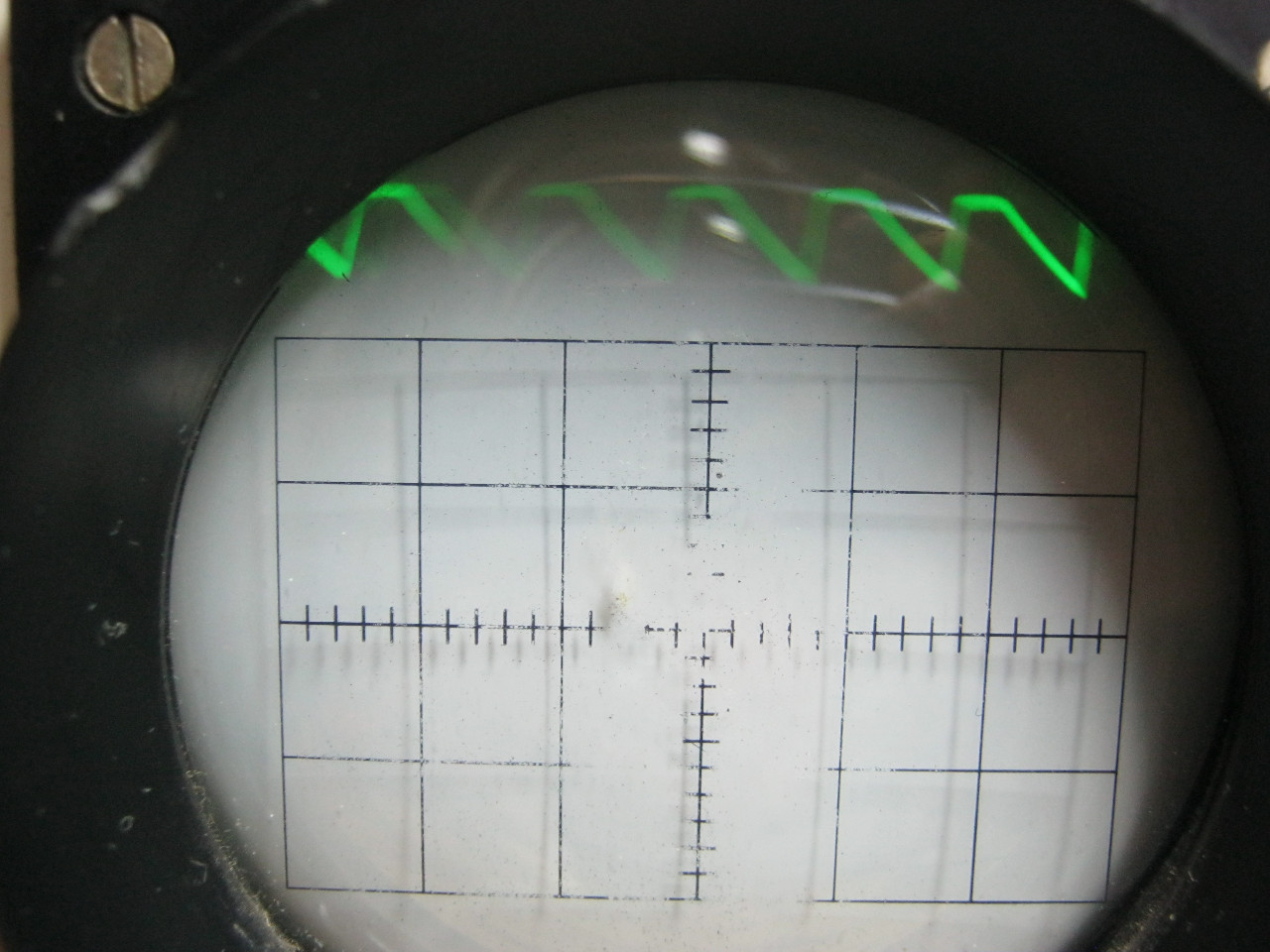

And here is the oscillogram from the Conder.

Nope... this is not a DC waveform. The pulsations still remained.

Well, let's take a container with a larger capacity.

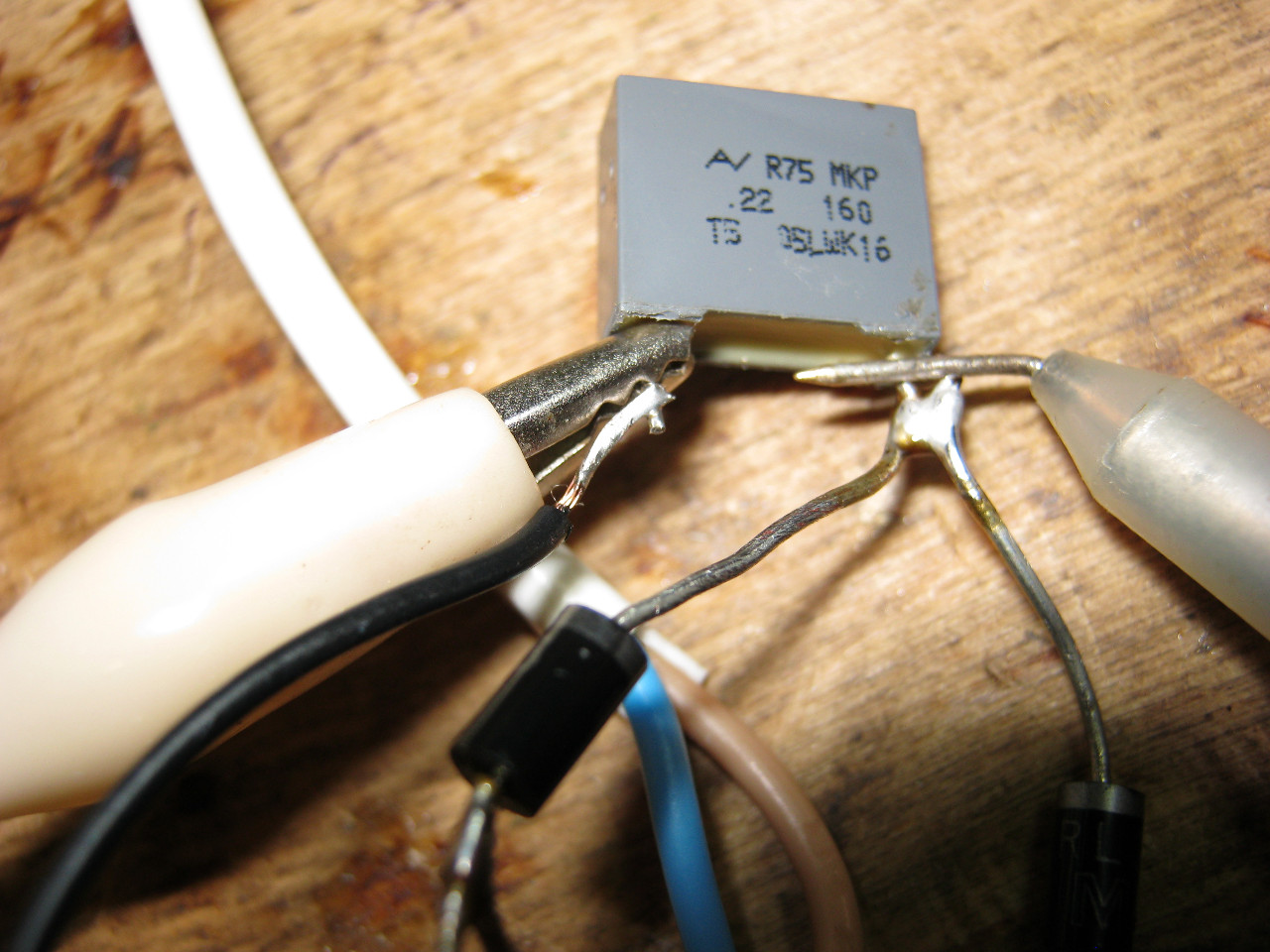

Let's measure its capacity. This turns out to be 0.226 microFarad.

We hook it to the diode bridge in the same way as the first condenser and take readings from it.

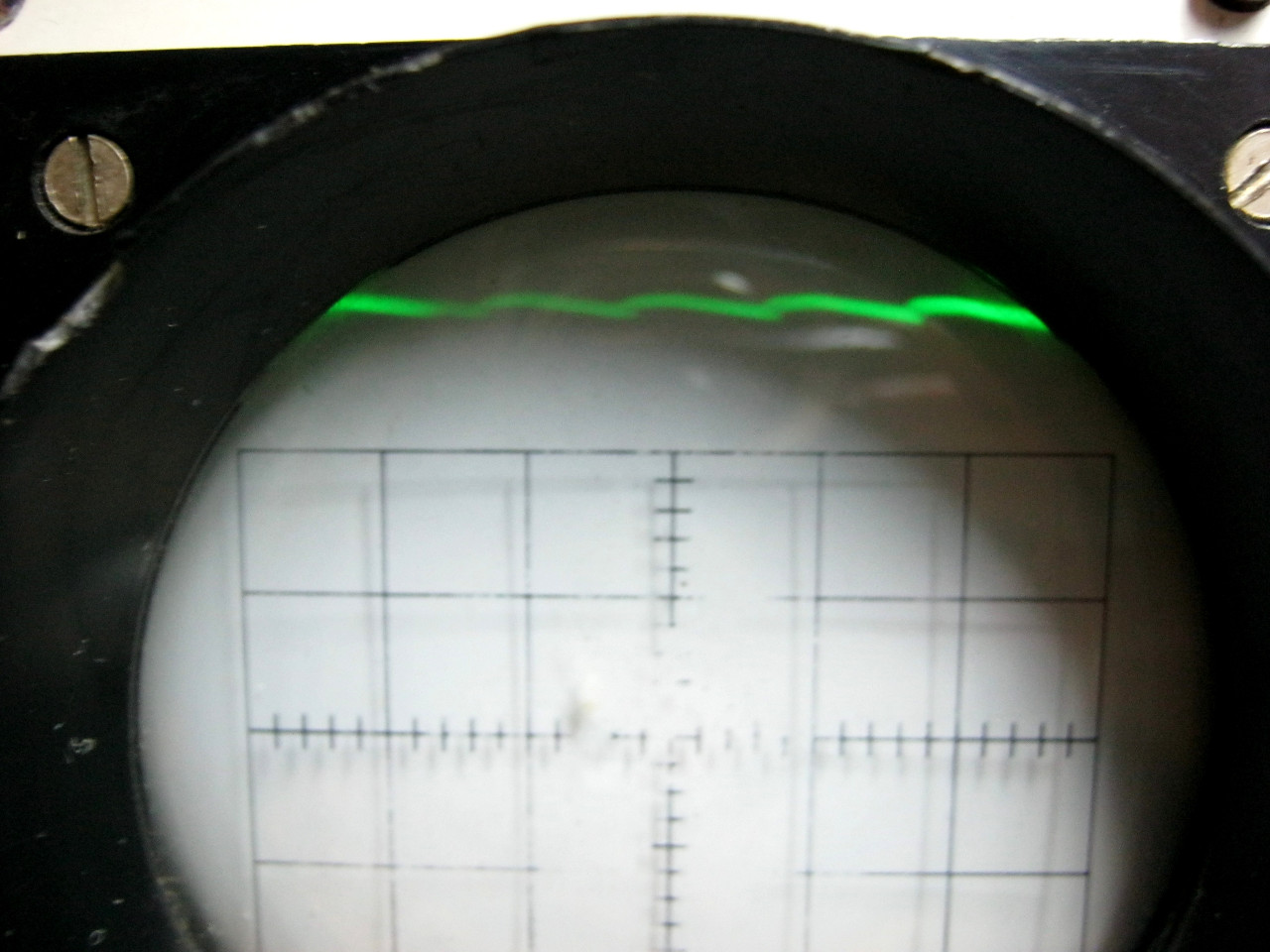

And here is the actual oscillogram.

Not... almost, but still not the same.

We take our third Conder. Its capacity is 330 microFarads. Even my LC meter cannot measure it, since my limit on it is 200 microfarads.

We hook it to the diode bridge and take an oscillogram from it.

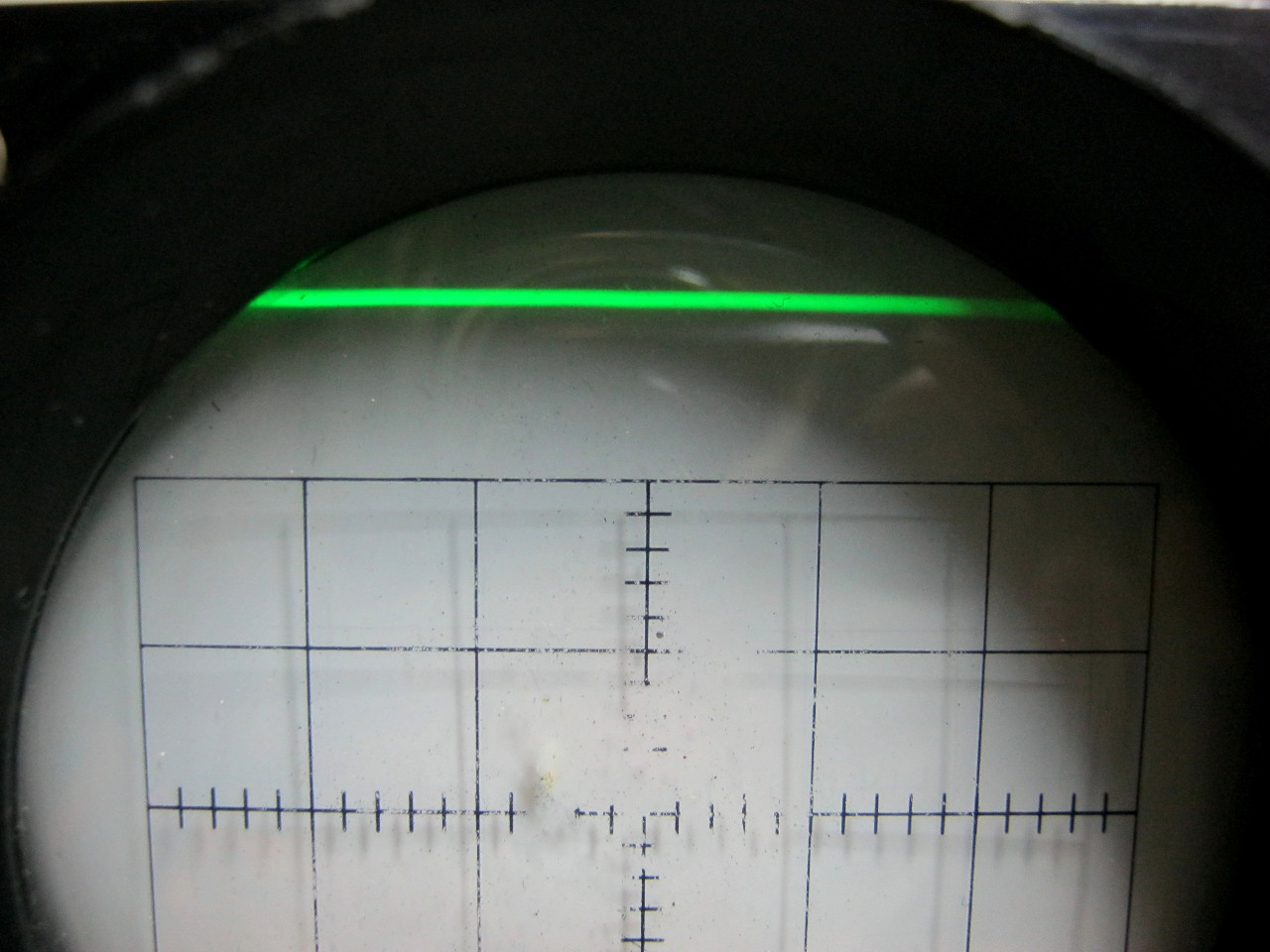

And here she actually is

Here you go. It's a completely different matter!

So, let's draw some conclusions:

The larger the capacitor at the output of the circuit, the better. But don’t overuse the capacity! Since in this case our device will be very large, because capacitors of large capacities are usually very large.

The lower the resistance the load at the output of such a power supply is, the greater the ripple amplitude will appear. In this case, it is best to use three-terminal voltage stabilizers, which produce the purest DC voltage.

Let's return to our question at the beginning of the article. How do you still get a direct current of 12 Volts at the output, say, for some trinkets? First you need to select a trans so that at the output it produces... 12 Volts? But they didn’t guess right! Co secondary winding trance we will receive effective voltage.

Where

U D- effective voltage

Umax- maximum voltage

Therefore, to get 12 Volts of constant voltage, the trance output must be 12/1.41 = 8.5 Volts. Now that's order. In order to obtain such tension on the trance, we must decrease or add the trance windings. Formula. Then we select diodes. We select diodes based on what we are going to power and what voltage and current should pass through the diodes. We are looking for suitable diodes using datasheets (technical descriptions for radio elements). We insert a condenser with a large capacity. We select the condenser based on the fact that the voltage on it does not exceed that written on its marking. The simplest constant voltage source is ready for use!

By the way, I got a 17 Volt constant voltage source, since the trance has 12 Volts at the output (multiply 12 by 1.41).

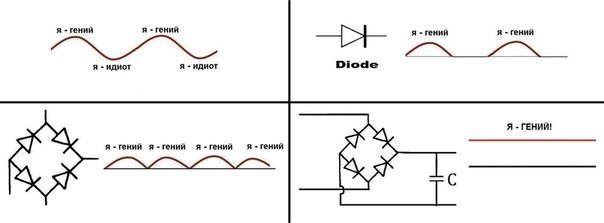

And finally, to make it easier to remember ;-)

We must read this article.