Choke for a drl 250 lamp. Ultraviolet - we get it at home quickly and for a penny

Topic: connection diagram, characteristics, device, operation of the DRL lamp.

DRL lamp(Arc Mercury Lamp) - a high-pressure arc mercury phosphor lamp. This is one of the varieties of electric lamps, which is widely used for general lighting of large areas such as factory floors, streets, sites, etc. (where there are no special requirements for the color rendering of lamps, but high light output is required from them). DRL lamps have a power of 50 - 2000 W and were originally designed to work in electrical networks alternating current with supply voltage 220 V. (frequency 50 Hz.). To operate the lamp, a ballast in the form of an inductive choke is required.

Now, as for the DRL lamp device. An arc mercury lamp (DRL) consists of three main functional parts: a base, a quartz burner and a glass bulb.

plinth is designed to receive electricity from the network, by means of connecting the lamp contacts (one of which is threaded, and the second is point) with the contacts of the cartridge, after which alternating electricity is transferred directly to the electrodes of the DRL lamp burner itself (electric arc mercury lamp).

Quartz burner is the main functional part of the DRL lamp. It is a quartz flask, which has 2 electrodes on the sides. Two of them are basic and two are additional. The burner space is filled with an inert gas "argon" (to isolate the heat exchange between the burner and the medium) and a drop of mercury.

glass flask is the outer part of the lamp. A quartz burner is placed inside it, to which conductors are suitable from the contact base. Air is pumped out of the flask and nitrogen is pumped into it. And another important element that is in a glass bulb is 2 limiting resistances (connected to additional electrodes). The outer glass flask is coated with a phosphor on the inside.

The first versions of DRL lamps had only two electrodes, which required an additional trigger device to ignite the DRL lamp (through a high-voltage pulsed breakdown of the gas gap of a quartz burner). This type of lamp was discontinued and replaced with a four-electrode analog, for which only a choke is needed.

The main characteristics of DRL lamps:

DRL lamp operation : mains voltage is applied to the lamp, it is supplied to the gap between the main and additional electrode, which are located on one side of the quartz burner and to the same pair located on the other side of the burner. The second gap, between which the mains voltage is concentrated, is the distance between the main electrodes of the quartz burner, located on opposite sides of it.

The distance between the main and additional electrodes is small, which makes it easy to ionize this gas gap when voltage is applied. The current in this section is necessarily limited by the resistances in the circuit of additional electrodes before the wire conductors enter the quartz burner. After ionization has occurred at both ends of the quartz burner, it is gradually transferred to the gap between the main electrodes, thereby ensuring further burning of the DRL lamp.

The maximum burning of the DRL lamp occurs after about 7 minutes. This is due to the fact that in the cold state, the mercury in the quartz burner is in the form of a drop or deposit on the walls of the flask. After starting, mercury slowly evaporates under the influence of temperature, gradually improving the quality of the discharge between the main electrodes. After all the mercury has gone into vapor (gas), the DRL lamp will reach its nominal operating mode and maximum light output. It should also be added that when the DRL lamp is turned off, it cannot be turned on again until the lamp has completely cooled down. This is one of the disadvantages of the llama, since it becomes dependent on the quality of the power supply.

The DRL lamp is quite sensitive to temperature and therefore an external glass bulb is provided in its design. It performs two functions: firstly, it serves as a barrier between the external environment and the quartz burner, preventing the burner from cooling down (nitrogen inside the bulb prevents heat transfer), and secondly, since not the entire visible spectrum is emitted during the internal discharge (only ultraviolet and green color), then the phosphor lying in a thin layer on inside glass bulb, converts ultraviolet light into a red light spectrum. As a result of the combination of blue, green and red radiation, a white glow of the DRL lamp is formed.

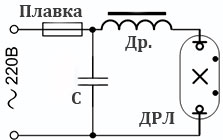

Four electrode lamps are connected to the mains through a choke. The inductor is selected in accordance with the power of the DRL lamp. The role of the inductor is to limit the current that feeds the lamp. If you turn on the lamp without a choke, it will instantly burn out, because too much electric current will pass through it. It is desirable to add a capacitor (not electrolytic) to the connection diagram. It will affect the reactive power, and this will save electricity twice.

Four electrode lamps are connected to the mains through a choke. The inductor is selected in accordance with the power of the DRL lamp. The role of the inductor is to limit the current that feeds the lamp. If you turn on the lamp without a choke, it will instantly burn out, because too much electric current will pass through it. It is desirable to add a capacitor (not electrolytic) to the connection diagram. It will affect the reactive power, and this will save electricity twice.

Choke DRL-125 (1.15A) \u003d capacitor 12 microfarads. (not less than 250 V.)

Choke DRL-250 (2.13A) = capacitor 25 microfarads. (not less than 250 V.)

Choke DRL-400 (3.25A) = 32 microfarad capacitor. (not less than 250 V.)

P.S. The DRL lamp contains droplets of mercury inside, if the quartz bulb breaks, then the mercury vapor will scatter in a room of 25 sq.m. Handle the DRL lamp with care.

Since high-pressure lamps DRL 250 have a rather long service life and high efficiency compared to incandescent lamps, they are successfully used to illuminate summer cottages, the courtyard of a private house, and sometimes even garages inside.

They have proven their reliability, quality of lighting for years, and all this for a small amount. Buying a DRL 250 lamp is not difficult. It is on sale both in specialized stores and in the markets.

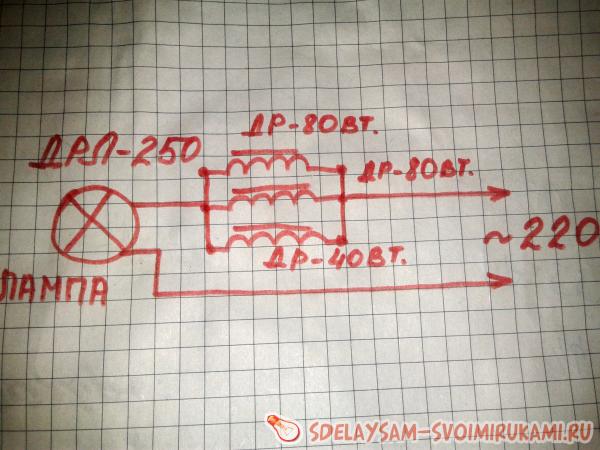

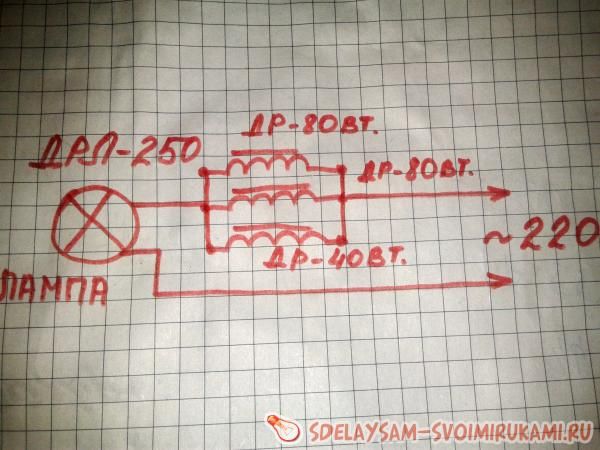

The problem may be the inductor, which is included in the lamp power circuit. Since it consists of copper wire, its cost, even used one, is quite high. Therefore, this article will describe how to make a choke for this lamp from other commonly encountered materials. For example, from the three chokes of the once common fluorescent lamps. Such chokes were used in lamps for LD 40 lamps, respectively, they had a choke of 40 watts. Also lamps for LD 80 lamps in which the chokes are rated at 80 watts. To replace the choke for a 250 watt DRL lamp, you will need two 80 watt chokes and one 40 watt choke. Their connection diagrams can be seen in the figure.

It can be seen here that all chokes are connected in parallel, that is, chokes connected in parallel form one common ballast.

One wire coming from the 220 socket connects to one end of the chokes, and the other wire in the 220 socket goes straight to the lamp. The wire from the output of the chokes goes to the second contact of the lamp. The option of mounting the chokes on the luminaire body can be seen in the photographs.

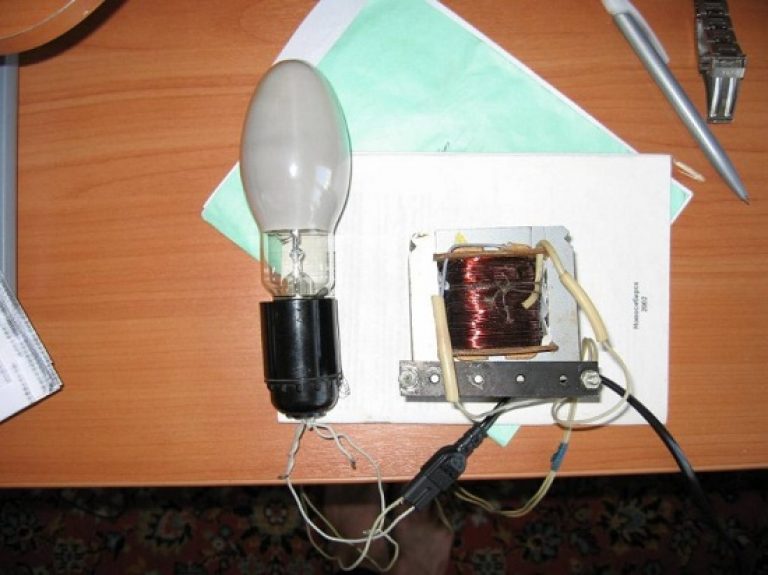

You can also see how the wires are connected here. It is very important to take care that the contacts on the terminals of the chokes have a good connection, otherwise they will spark and heat up. In the photo you can see how such a throttle works and starts the DRL 250 lamp.

This design has been made and tested with good results. In addition to mounting chokes on fixtures, you can make a separate box in which they will be located, and bring the wires from it to the lamp. This assembly option will cost much less than buying a special throttle. I would like to remind you that according to the rules for installing DRL lamps, they must be at a height of at least three meters. Since it is believed that they emit a lot of ultraviolet light, and this is undesirable for human skin.

That's all. Try and you will succeed.

The word throttle has been heard by many. However, few people know what it means. What device is called a choke? What does it look like? What functions does it perform?

Throttle usually invisible to humans. That is why few people know about its existence. And this despite the fact that at present none of the varieties of mercury lamps can work without it. A choke is a device that can rightfully be called the main part of ballasts installed in modern lighting devices.

From German, the word throttle can be translated as a limiter. This is its first task - to limit the amount of voltage that is applied to the electrodes of the lamp when it is working. The second function is to create for a short period of time high voltage required to turn on the lamp.

The principle of operation of the inductor is the process of a short-term appearance of voltage in the coil at the moment an electric current passes through it. The values of current and voltage are carefully calculated and differ for certain models of these devices. These parameters help to break through the gaseous medium with the help of a discharge of electrical energy. After turning on the lamp, the throttle becomes a limiter. A working lamp is no longer needed great importance voltage. This feature made it more economical than other types of lamps.

Different lamps need different chokes. For example, a choke to a HPS lamp will not function with mercury lamps. This is due to the difference in the amount of current and voltage needed to start, which ensures the full operation of the lamp. But MGL lamps will work with both types of chokes. True, in each individual variant, the brightness and color temperature of the lamp will change.

An interesting fact is that the life of the inductor is much longer than the life of the lamp itself (if you follow all the operating rules). Over time, the lamp "gets old". As a result, the ballast begins to heat up and even overheat. This leads to the fact that the system simply turns off or a short circuit occurs. Therefore, it is important to change when their service life ends. To avoid problems, you can sometimes measure the voltage value in the lamp. This way you can avoid failure PRA, which costs much more than a lamp. Currently, lamps with a built-in automatic fuse are becoming more and more popular.

According to their purpose, chokes are divided into several types. They can be single phase or three phase. They can work with 220V and 380V networks. Due to their design, which provides for the presence of special protection, some types of chokes can work outdoors or in extreme conditions.

For long and high-quality operation of the throttle, it is important that it fully meets all the requirements stated for it.

Since DRL 250 high-pressure lamps are distinguished by their durability, reliability and high efficiency compared to standard incandescent lamps, they are often used to create lighting in summer cottages, in courtyards of private houses, garages, etc. By themselves, such lamps are quite simple to purchase at any specialized store, they have a very reasonable price and are very common. The problem is that the inductor that is included in the lamp power circuit is made of copper and can cost much more. Therefore, the author decided to try to make a similar throttle on his own.

Materials and tools that the author used to create home-made chokes for the DRL 250 lamp:

1) 40 watt chokes from the lamp LD 40

2) 80 watt chokes from LD 80 lamps

3) wires

4) blowtorch

5) soldering accessories

Let us consider in more detail using the example of photographs how to assemble a home-made choke for DRL 250 lamps.

As mentioned above, conventional chokes for the DRL 250 lamp are quite expensive, as they consist of copper wire. So he decided to make it himself from cheaper similar materials. As such materials, the author chose other chokes from less powerful fluorescent lamps.

Before using DRL 250 lamps, the author used LD 40 and LD 80 lamps, which have 40 and 80 watt chokes, respectively. Therefore, it was decided to create a throttle for the DRL 250 from them. After making some calculations, the author found that for one DRL 250 inductor, at least two 80-watt inductors and one 40-watt inductor are needed.

Below is a diagram of their connection:

As can be seen from the diagrams, all chokes are connected in parallel, thus forming a common ballast. This is important, since when the chokes are connected in series, the inductance will add up and the inductive reactance will increase accordingly. Therefore, when connected in series, the current will be limited at the level of a 20-watt lamp.

The author connected one of the wires coming from the outlet of a standard 220 V outlet to one of the ends of the inductor, and put the other wire from the outlet directly onto the lamp. The wire that comes from the output of the chokes, the author connected to the second contact of the lamp. The practical application of such a scheme is presented in the photographs below:

In these photos it is also noticeable how the wires are connected. The author notes that it is necessary to make sure that the contacts on the terminals of the inductors have a good enough connection, otherwise they will spark and heat up, which can lead to breakage.

The following photo shows how such a throttle works and that it is able to start the DRL 250 lamp:

According to the author, such a scheme is reliable enough for use. So he suggests in the future to use a separate box in which the chokes will be located, and simply bring the wires from it to the lamps. This assembly option cost the author less than buying a special choke for the DRL 250 lamp. The author also recalls that during testing, special attention should be paid to safety, and he also advises placing the lamps at a height of at least three meters, since he believes that they are studying quite a lot of ultraviolet.

General purpose high-pressure mercury lamps (DRL) are intended for indoor and outdoor lighting fixtures, electrical networks with a frequency of 50 Hz and a voltage of 220 volts.

For their use, appropriate ballasts are required.

1 Applications

The DRL lamp has a high luminous efficiency, resistance to mains voltage fluctuations, cheap ballasts that do not require pulse igniters, and a long service life.

It is used to illuminate:

- streets;

- area;

- industrial shops;

- warehouses.

1.1 How do DRL lamps work?

Initially, DRL lamps had two electrodes. This required another trigger, a high-voltage pulse test of the burner gap. The variety was discontinued, it was replaced by a 4-electrode version. To commit arson, you need to connect the throttle.

The main purpose of this element of the electrical circuit is to reduce the influence of range currents over a certain period of time. A choke is a type of inductor.

For operation, an alternating mains current is used. It goes to the gap between the additional and main electrodes, which are located on one side of the burner on the same pair of electrodes, they are located on the other side of the quartz burner. The connected current is concentrated in the gap between the main electrodes of the burner, they are located on opposite sides.

The distance between the electrodes is quite small. Due to this gap, the gas is easy to ionize, applying the desired voltage to it. The current that arose after a breakdown in the section is limited by electrical resistance. It is located in electrical circuit auxiliary electrodes that stand in front of the conductors entering the burner.

The discharge passes to the area between the electrodes of the quartz burner as soon as ionization begins at its ends. Next comes combustion.

The drl lamp reaches the maximum burning mode after 7 minutes. This happens due to the fact that unheated mercury is under the guise of plaque or droplets on the walls of the flask. After the start-up, the mercury lump evaporates under the influence of temperature, and the discharge between the working electrodes gradually improves.

After the transformation of mercury into a gaseous state, the lamp returns to its nominal operating mode. It must be remembered that after turning off, it will not turn on again until the lamp has completely cooled down.

The lamp is very sensitive to temperature, so it needs an external glass bulb.

It has 2 functions:

- Serve as a barrier between the burner and the medium.

- Convert ultraviolet to red light spectrum.

2 DRL lamp device

The DRL lamp has three main functional parts: a glass bulb, a quartz burner and a base. The outer part is a glass flask. Inside it is a quartz burner, to which conductors from the contact base are suitable. Air is pumped out of the flask and filled with nitrogen.

There are two limiting resistors in the bulb. The outer surface of the glass bulb inside is covered with a phosphor and a drop of mercury.

2.1 Wiring diagram for a mercury arc lamp

To connect the drl lamp, you need to use special ballasts. These devices are different from those used to connect fluorescent lamps.

After switching on, a discharge occurs between the main and additional electrodes. The gas ionized in the burner ensures the ignition of this discharge. between the main electrodes. After the lamp is ignited, the discharge between the auxiliary and main electrodes ends.

The inductor as a ballast device limits the lamp current and stabilizes it if there are deviations in the mains voltage.

Resistors will limit the current when the lamp is lit. The current at the moment of ignition exceeds the nominal by 2 - 2.6 times. As the burner warms up, the current decreases, and the voltage increases from 65 to 130 V. The ignition lasts 5-10 minutes. The temperature of the outer flask in the operating mode exceeds 200 degrees.

2.3 Lamps with DRL lamps

For outdoor street lighting To make it comfortable and convenient in the dark, use various lighting devices. Each of them differs in type, shape, power, light elements used, mounting methods and other characteristics. One of the most common— lamps drl.

These lighting fixtures are:

- power;

- brightness;

- durability;

- frost resistance;

- economy.

Two types of lamps are made for drl lamps, which best meet the scope of use. Console lamps are used for poles, they are mounted at an angle of 15 degrees relative to the horizontal. Designed for one or more lamps.

They have a built-in or external choke. Reflectors and housing are made of special sheet steel. The plafond has a protective glass dome or a metal grille.

Floor lamps are made in the form of a transparent or matte ball of glass or polycarbonate. The base is a pole, a decorative pipe or a support. Floor lamps with the shape of an inverted cone are also produced. The throttle is located inside the base of the ceiling. This is a decorative type of lamp, it is intended for decorating the lighting of the site.

The LPO luminescent lamp, which has a simple design, is perfect for lighting various rooms. Such a lamp can provide stable lighting in a wide voltage range.