Laying a high voltage cable in the ground. Cable laying in the ground

Julia

Hello! A high-voltage cable was laid underground in our yard between two multi-storey buildings, at present the territory has been asphalted and a parking lot has been made. Are the actions legal? Thanks for the help.

Answer:

The cable laying under the asphalt parking lot was carried out in accordance with the current norms and requirements. When laying cables under asphalt pavements with heavy traffic, cable lines must be laid in pipes or blocks to a depth of at least 1 meter from the planning mark.

Cable laying in the ground under roads

PUE-6

2.3.17. The structures of underground cable structures must be calculated taking into account the mass of cables, soil, road surface and the load from passing traffic.

2.3.30

On streets and squares saturated with underground utilities, it is recommended to lay cable lines in the amount of 10 or more in a stream in collectors and cable tunnels. When crossing streets and squares with improved coatings and with heavy traffic, cable lines should be laid in blocks or pipes.

2.3.83

When laying cable lines directly in the ground, the cables must be laid in trenches and have backfilling from below, and backfilling from above with a layer of fine earth that does not contain stones, construction debris and slag.

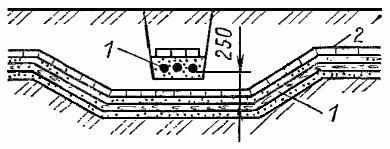

Cables throughout their entire length must be protected from mechanical damage by coating at a voltage of 35 kV and above with reinforced concrete slabs with a thickness of at least 50 mm; at voltages below 35 kV - with slabs or ordinary clay bricks in one layer across the cable route; when digging a trench with an earthmoving mechanism with a cutter width of less than 250 mm, as well as for one cable - along the route cable line.

The use of silicate, as well as clay hollow or perforated bricks is not allowed.

When laying at a depth of 1 - 1.2 m, cables of 20 kV and below (except for city power cables) may not be protected from mechanical damage.

Cables up to 1 kV should have such protection only in areas where mechanical damage is likely (for example, in places of frequent excavation). Asphalt pavement of streets, etc. are considered as places where digging is carried out in rare cases. For cable lines up to 20 kV, except for lines above 1 kV, supplying electrical receivers of category I *, it is allowed to use signal plastic tapes instead of bricks in trenches with no more than two cable lines that meet the technical requirements approved by the USSR Ministry of Energy. It is not allowed to use signal tapes at the intersections of cable lines with utilities and over-cable couplings at a distance of 2 m in each direction from the crossed communication or coupling, as well as at the approaches of lines to switchgears and substations within a radius of 5 m.

____________

* According to local conditions, with the consent of the owner of the lines, it is allowed to expand the scope of signal tapes.

The signal tape should be laid in a trench above the cables at a distance of 250 mm from their outer covers. When one cable is located in a trench, the tape should be laid along the axis of the cable, with a larger number of cables, the edges of the tape should protrude beyond the outermost cables by at least 50 mm. When laying more than one tape across the width of the trench, adjacent tapes must be laid with an overlap of at least 50 mm wide.

When using a signal tape, laying cables in a trench with a cable cushion device, sprinkling the cables with the first layer of earth and laying the tape, including sprinkling the tape with a layer of earth along the entire length, must be carried out in the presence of a representative of the electrical installation organization and the owner of the power grid.

2.3.84

The depth of cable lines from the planning mark should be at least: lines up to 20 kV 0.7 m; 35 kV 1 m; at the intersection of streets and squares, regardless of voltage 1 m.

Cable oil-filled lines 110 - 220 kV must have a laying depth from the planning mark of at least 1.5 m.

It is allowed to reduce the depth to 0.5 m in sections up to 5 m long when lines are introduced into buildings, as well as at their intersections with underground structures, provided that the cables are protected from mechanical damage (for example, laying in pipes).

The laying of cable lines 6 - 10 kV on arable land should be carried out at a depth of at least 1 m, while the strip of land above the route can be occupied by crops.

2.3.97

When cable lines cross railways and roads, cables must be laid in tunnels, blocks or pipes across the entire width of the exclusion zone at a depth of at least 1 m from the roadbed and at least 0.5 m from the bottom of drainage ditches. In the absence of an exclusion zone, the specified laying conditions must be met only at the intersection plus 2 m on both sides of the roadbed.

When cable lines cross electrified and subject to electrification on DC* railways blocks and pipes shall be insulating (see 2.3.90). The crossing point must be at least 10 m away from switches, crosses and places where suction cables are attached to the rails.

The intersection of cables with the tracks of electrified rail transport should be carried out at an angle of 75 - 90 ° to the axis of the track.

_____________

* Agreed with the Ministry of Railways.

The ends of the blocks and pipes must be insulated with jute braided cords coated with waterproof (crumpled) clay to a depth of at least 300 mm.

When crossing dead-end industrial roads with low traffic intensity, as well as special routes (for example, on slipways, etc.), cables, as a rule, should be laid directly in the ground.

When crossing the route of cable lines by a newly constructed non-electrified railway or a motor road, it is not required to re-lay existing cable lines. At the intersection, reserve blocks or pipes with tightly sealed ends should be laid in the event of repair of cables in the required number.

In the event of a cable line transitioning into an overhead line, the cable must exit to the surface at a distance of at least 3.5 m from the bottom of the embankment or from the edge of the canvas.

2.3.99

When cable lines cross entrances for vehicles to yards, garages, etc. cables should be laid in pipes. In the same way, cables must be protected at the intersection of streams and ditches.

Read also:

Elena Good afternoon! Tell me, please, in what cases is it possible to lay a cable in the ground in steel tubes? And in what literature can one read about it? Answer: Cable laying in the ground is carried out in asbestos-cement pipes, ...

Dmitry Tell me, please, the answer to the question: power (VVG) and low-current cables are laid in HDPE pipes on the territory of the cottage. Is it necessary at the places of their intersection with gas or heat pipelines according to the document ...

Nadezhda Please tell me how far a high-voltage cable should be removed from a residential building, laid underground? Is there any SNiP for laying such a cable? Answer: When laying a cable in the ground, the distance ...

Alexey Hello! Such a situation: a wooden 2-storey school combined with a kindergarten (1st floor of a kindergarten, 2-school), air entry, the support stands about five meters from the school to the fence of the school territory, that is, on the school ...

Sergey Neighbor in the garden plot laid a power cable in the ground, from the overhead line pole to his house right under the fence. Can this wiring be done? In winter, fence posts will “play” and can ...

6 Comments on ”Are they allowed to lay cable under an asphalted car park?”

-

Hello Ivan!

Your question has been redirected to . You can register on the forum and discuss "" in more detail with the forum participants. Hello, Alexander!

Your question has been redirected to . You can register on the forum and discuss in more detail "

The question is, there are existing cables 2 x 0.4 kW and 2 x 10 kW (underground), mountains. the network does not mind us crossing them, building a building with 2-story floors and a concrete floor. It turns out that the cables will pass under the building, there is no basement, they demand to provide an intersection solution for issuing a building permit. Are there any standard solutions?

The cable is one of the main elements of power supply for businesses or residential facilities. Cable laying methods are selected based on the cost and speed of work, as well as technical project- by air, in blocks, pipes, in a trench, using supports or trays.

Placing the cable in an earthen trench is one of the cheapest types of cable installation. Laying high-voltage cable in the ground is designed and implemented in such a way as to exclude the possibility of mechanical damage to the cable during operation. Laying an electrical cable in the ground gives a big plus to the organization of cable cooling at the expense of the earth.

Cable laying technology

According to the technology, the cable is laid with a small margin in case of mechanical displacement of the soil and taking into account deformation with temperature changes. In practice, this means wavy laying of the cable, if it is placed in a trench, and the creation of a sag, if the cable is carried along structures. The creation of cable rings for stock is unacceptable. In the case of vertical laying, rigid fastening is used in the form of gaskets made of sheet rubber, polyvinyl chloride or elastic material, calculated for the corresponding temperature range.

Installation is carried out in two stages - the creation of support structures for laying and direct work on laying the cable and connecting it to the outlets. I lay cables at a height of more than 2 meters.

Cable laying standards

According to the norms, the cable must be laid to a depth of at least 0.7 meters. It is allowed to place no more than 6 cores in one trench (at a voltage of 6-10 kW) and no more than two, at a voltage of 35 kW. The width of the trench should be chosen based on the convenience of work, however, it should be at least 20 cm at voltages up to 10 kW, and at least 30 cm at 35 kW. With more than 20 cables, it is justified to organize their placement in the tunnel.

Tests

The cable is delivered to the facility in its original packaging - a drum. After removing the outer casing of the drum, it is necessary to assess the condition of the insulation shell of the outer turns for smudges, cracks, displacements or gaps between the turns of the armored tape. The cable damaged during transportation is removed, and the remaining one is tested with increased voltage.

Laying a control cable in the ground must be accompanied by a test of its characteristic impedance in order to detect faults or damage during installation.

When laying the cable at negative temperatures, it is necessary to take into account the ambient temperature. Under the condition of installing a cable heated in the room, the speed of its installation on the street is selected from the following temperatures:

- From 0 to minus 10 degrees - installation time is no more than an hour;

- From minus 10 to 20 degrees - installation time is no more than 40 minutes;

- At temperatures below 20 degrees - the installation time is no more than 30 minutes.

At temperatures below 40 degrees, laying a cable of any brand is prohibited. Cable laying in the ground, inspection of electrical equipment, electrical testing, installation and many other works related to electrical equipment can be carried out by the 10 Kilovolt company. At your service - a staff of highly qualified specialists and their invaluable experience.

Video: laying a high-voltage cable in the ground

Conditions and benefits of underground cabling

Laying cables in the ground is the most economical. In addition, unlike overhead lines, cable installation in the ground is not subject to heavy snowfalls, storm winds and is not damaged by fallen trees. Cable lines, to a lesser extent than air lines, are subject to dangerous and interfering electromagnetic influences created in communication, signaling, automation and telemechanics circuits by various power lines and contact networks electric railways, as well as the effects of atmospheric surges (lightning discharges).

Cable lines provide better continuity, high quality and reliability of communication and signaling devices, are more durable and cheaper to operate, although their construction is more expensive. Damage on cable lines occurs much less frequently than on overhead lines.

For cable lines laid in the ground, armored cables should be used predominantly. The metal sheaths of these cables must have an outer jacket to protect them from chemical attack. If unarmored cables are laid, then it is required to first lay asbestos-cement or PVC pipes, which will reliably protect it from

accidental mechanical damage during subsequent excavations. If the cable is armored, then its use will also require the laying of pipes at the intersection of railway and tram rails, highways and dirt roads, under the carriageways of streets, at intersections with underground structures and other cables so that the ends of the pipes extend 1 m outside the intersection, as well as when entering the cable into a building or structure.

Cables are protected when they are laid in rocky soils at a depth of 0.5 m, in orchards and orchards, when ten or more signal and other cables are laid in one trench, as well as when power cables with an operating voltage higher than 1 kV. In these cases, the cable is covered with concrete slabs or a layer of red brick for protection.

The whole procedure for underground cable laying includes several stages:

- selection and coordination of the cable laying route,

- marking and breakdown of the route,

- trench digging

- arrangement of bedding (pillow) from shallow earth without stones or sand,

- laying of protective pipes (if provided by the project),

- preparation of the cable for laying,

- cable laying (if the cable is laid in pipes, then pulling the cable in pipes),

- installation of couplings,

- backfilling the cable with fine earth without stones or sand,

- protection of the cable with red clay bricks or asbestos-cement boards,

- laying a signal and warning tape (if provided by the project),

- drawing up an act of hidden works,

- electrolaboratory tests of the cable line and backfilling of the trench with soil.

All these electrical work must be carried out in the order in which they are listed.

The choice of route for laying the cable

The cost of construction of cable lines and networks, their durability, as well as reliability and uninterrupted operation depend on the correct choice of the route. The route of underground cable lines is chosen based on the fact that the length of the cable laid between the given points is the smallest and the convenience of the cable laying and its further work is ensured. maintenance and operation.

Any electrical installation work related to excavation of the earth and laying the cable into the ground must be started only after obtaining permits for laying the cable, since other engineering systems can be laid in the ground, and you can damage them, or lay the cable in violation of existing standards.

If earthworks are carried out in settlements, then before they begin, the customer is obliged to issue a permit from the territorial administration to carry out the work provided for by the project and transfer it to the contractor.

The contractor is obliged, on the basis of a permit, to obtain a work order.

The order specifies:

a) last name, first name, patronymic and position of the person responsible for the work;

b) the term for the completion of construction work at the facility, linked to the submitted project for the production of works;

c) organizations responsible for the restoration of road surfaces, replanting of green spaces and the timing of these works;

d) organizations whose representatives must be called to the site before the start of earthworks.

Working documentation, an order for the right to carry out work and a copy of a written notification document must be located at the place of work.

Earthworks within the security zones of existing underground structures (power and communication cables, pipelines, etc.), as well as above-ground structures at their intersection (railways, highways), when laying a cable along the side of the road, etc., are allowed only if written permission of the organization operating these facilities and in the presence of its representative, as well as the responsible work executor. The execution of works in such places must be agreed and reflected in the project documentation.

The construction organization is obliged, no later than three days before the start of earthworks, to notify in writing about the forthcoming work, and one day before, to call representatives of interested organizations to the place of work to clarify the location of their structures and agree on measures to prevent damage to these structures. Prior to the arrival of representatives, excavation is prohibited.

The route before digging a trench should be inspected to identify places on the route containing substances that have a destructive effect on the cable sheath (salt marshes, lime, water, bulk soil containing slag or construction waste, areas located closer than 2 m from sewage, cesspools and garbage pits etc.). If it is impossible to bypass these places, the cable should be laid in clean neutral soil in asbestos-cement pipes with their additional sealing. When filling the cable with neutral soil, the trench should be further expanded on both sides by 0.5-0.6 m and deepened by 0.3-0.4 m.

underground cable laying and cable duct in settlements, it is advisable to produce along the streets,

In cities and towns, the laying of cables in the ground (in trenches) is carried out along the impassable part of the streets (under the sidewalks), in the yards and technical lanes in the form of lawns, with shrub plantings, which have the least load of other underground structures (water supply, sewerage, gas pipeline, power cables etc.), so as to less disturb traffic during the work on laying the cable line and its operation. On streets and squares saturated with underground utilities, it is recommended to lay cable lines in collectors and tunnels. When crossing streets and squares with improved coatings and with heavy traffic, cable lines should be laid in blocks or pipes.

Preliminary drilling should be carried out to accurately determine the underground structures intersected by the route of the laid communication cable or cable duct.

Pit holes should have a length of 1 m along the axis of the future trench. In the event that underground structures run parallel to the future route, the pits must be dug perpendicular to its axis every 20 m. The length of each pit must exceed the width of the designed trench on each side by at least 0.3 m.

If underground structures not specified in the working drawings are found during earthworks, work must be immediately stopped until the purpose of these structures is clarified and further work is agreed with their owners.

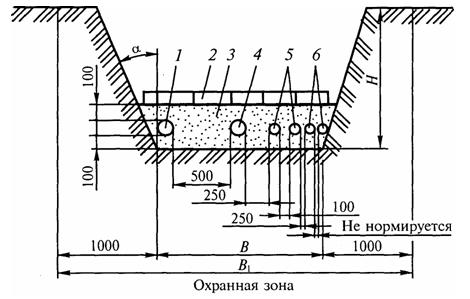

When laying in the ground in parallel with other operated cables or utilities near buildings and structures, clear distances (at least) must be observed;

- between cables up to 10 kV - 0.1 m (the same distance for parallel laying of newly laid cables);

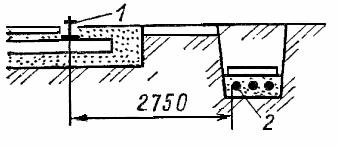

- from 35 kV cables - 0.25 m (Fig. 1.1);

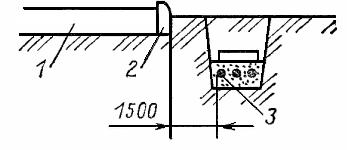

- from cables operated by other organizations and communication cables - 0.5 m (Fig. 1.2);

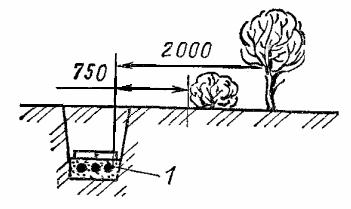

- from the cable to forest plantations - at least 3 m, from tree trunks - 2 m and from artisanal plantings - 0.75 m (Fig. 1.3);

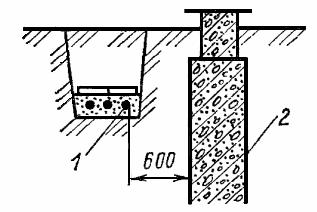

- from the foundations of buildings and structures - 0.6 m (Fig. 1.4);

- from pipelines, water supply, sewerage, drainage, low and medium pressure gas pipelines - 1 m (Fig. 1.5);

- from high pressure gas pipelines and heat pipelines - 2 m (Fig. 1.6);

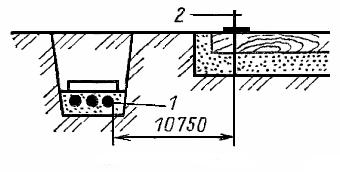

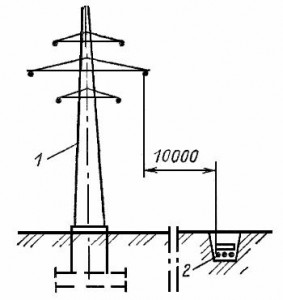

- from the electrified railway - 10.75 m (Fig. 1.7);

- from tram tracks - 2.75 m (Fig. 1.8);

- from the road from the edge - 1 m;

- from the curb stone - 1.5 m (Fig. 1.9);

- from the extreme wire of the 110 kV overhead line - 10 m (Fig. 1.10);

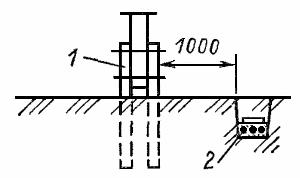

- from the support of the 1 kV overhead line - 1 m (Fig. 1.11).

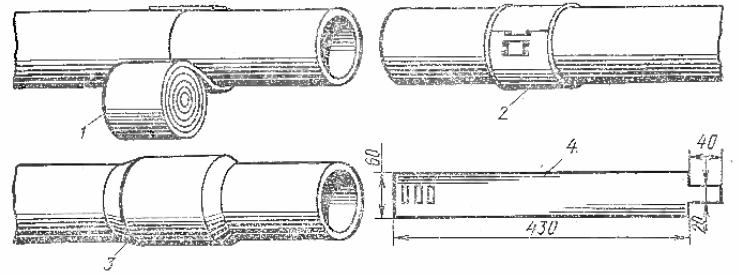

Rice. 1.1. Laying 1-10 kV cables in parallel with 35 kV (20 kV) cables:

1 - cable 20 kV;

2 - cable 35 kV;

3 - cable 10 kV;

4 - sand;

5 - reinforced concrete slabs

Rice. 1.2. Laying cables 1-10 kV with communication cables and power cables up to 10 kV operated by other organizations:

1 - cable 10 kV; 2 - cable 1 kV; 3 - communication cable or power cable of another organization; 4 - sand; 5 - bricks or slabs

Rice. 1.3. Laying cables near shrubs and trees:

1 - cable 1-10 kV

Fig 1.4. Laying cables near the foundation of the building and structures:

1 - cable 1-10 kV; 2 - foundation

Rice. fifteen. Laying cables parallel to pipelines, water pipes, sewerage, drainage, low and medium pressure gas pipelines:

1 - pipeline; 2 - cable 1-10 kV

Rice. 16. Laying cables near heating mains and high pressure gas pipelines:

1 - tray; 2 - cable 1-10 kV

Fig 1.7. Laying cables in parallel with an electrified railway:

1 - cable 1-10 kV; 2 - rail head

Rice. 1.8. Laying cables in parallel with tram tracks:

1 - rail head; 2 - cable 1-10 kV

Rice. 1.9. Laying cables parallel to the road:

1 - roadbed; 2 - curb stone; 3 - cable 1-10 kV

Rice. 1.10. Laying cables next to an overhead power line with a voltage of 110 kV:

1 - VL support; 2 - cable 1-10 kV

Rice. 1.11. Laying cables near the overhead power line up to 1 kV:

1 - VL support; 2- cable 1-10 kV

It is allowed to reduce the listed distances in cramped conditions, but this must be specified in the project and measures must be taken to protect cables in pipes or blocks.

When crossing other cable lines or utilities and structures, clear distances must be at least:

- from cables with voltage up to 10 kV - 0.25 m (Fig. 1.9);

- from pipelines, heat pipelines, gas pipelines - 0.5 m (Fig. 1.10);

- from the bed of railways, tramways, highways - 0.6 m.

Rice. 1.12. Crossing of cable routes with voltage up to 10 kV:

1 - cable up to 10 kV; 2 - bricks

Rns. 1.13. Crossing of cables with pipelines, water and gas pipelines:

1 - cable up to 10 kV; 2 - pipeline

In case of accidental damage to any underground structure, the responsible work executor is obliged to immediately stop work in this place, take measures to ensure the safety of workers, and report the incident to his supervisor and to the emergency service of the operating organization.

If gas is found in trenches or pits, work in them must be immediately stopped, and people removed from the danger zone. Work can be continued only after the cessation of further gas supply.

All structures damaged during the development of trenches (cuvettes, spillways, ditches, canals, embankments, improved coatings, fences, etc.) must be restored.

On arable lands, the fertile soil layer should be recultivated. The scope and conditions for performing reclamation work are determined by the project documentation.

Signal cables can be laid without restriction in the same trench with power cables with operating voltage up to 500 V

Signal cables, when crossing them with power cables and other underground structures, should also be laid at a distance of 0.5 m from these structures;

if this distance cannot be maintained according to local conditions, then it is allowed to reduce it to 0.3 m. At the same time, at the intersection of the signal cable with power cables, it must be laid in an asbestos-cement pipe. The distance between signal cables crossing each other must be at least 0.1 m.

Marking and breakdown of the route, preparation of trenches for cable laying

Before laying the cable, the route is laid out, which is selected during the design process, taking into account the least amount of construction work, the maximum use of mechanisms, the convenience of maintenance and the minimum cost of work to protect cables from corrosion, dangerous influences and damage from lightning strikes. The breakdown of the route is carried out in accordance with the working drawings, deviation from which is allowed only upon agreement with the customer or the design organization.

The cable laying route is chosen as straight as possible. Areas with calcareous soils, sewage, landfills and other places that are dangerous in terms of corrosion should be bypassed. The locations of existing underground structures are determined by technical documentation or using cable finders and by drilling.

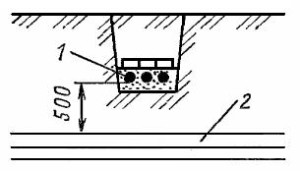

On the slopes of ravines, steep ascents and descents over 30° and up to 45°, the trench should be dug in a zigzag pattern (“snake”), with a maximum deviation from the axial straight line of 1.5 m over a length of 5 m. With slopes from 30° to 45° a cable is laid with conventional armor, and with slopes over 45 ° - with wire armor.

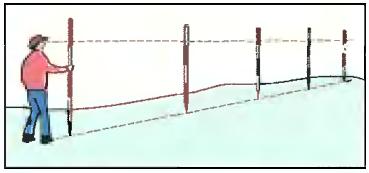

The marking and breakdown of the route of the underground cable line is carried out in accordance with the working drawings with the help of milestones and / or pegs in the center of the future trench and at its turns, as well as in straight sections after about 50 m along its length, stakes are driven in, which serve as starting points points for laying out the trench.

If the route comes in places where there are no permanent landmarks, the breakdown is done as follows. In the centers of excavation of two adjacent pits for the viewing device, the first milestone is installed with a height of 3 to 4 m with a red flag, after 40-50 m, the second milestone is placed (in the turning or main intermediate center) so that it can be seen from the side of the first milestone, and in this way, two points are obtained on the axis of the trench, the third milestone is made in the interval between milestones No. 1 and 2. Then, milestone No. 3 is installed between the first and second milestones so that it is in alignment (on the same line) with the first and second milestones. The third and subsequent milestones are installed from the side of the first one every 40 to 50 m.

The installation sites of milestones are fixed with pegs. The pegs used for laying out the tracks should have a length of 30 to 40 cm and a diameter of 3 to 4 cm. To drive a peg, a nest is prepared with a crowbar. Pegs should be driven into the ground to a depth of 100 to 150 mm.

At a distance equal to half the width of the trench from the pegs, a cord should be pulled, indicating the line of one of the edges of the trench.

If there are permanent landmarks, the route can be staked out without sighting by milestones. The final route is marked with a fender cord, applying two parallel lines with chalk or paint, which determine the required trench width.

In the event that the breakdown reveals a discrepancy between the working drawings and the need to perform work with a deviation from the design data, the construction organization must invite representatives of the customer and the design organization to resolve the issue of changing the route, which is documented by an act or correction of the working drawing, which must be certified signatures of representatives of the customer, design and interested organizations.

The following must be taken into account when staking trails:

a) the crossing of streets by underground structures of the GTS should be carried out at an angle of 90 ° to the axis of the street, only if this is not possible, a deviation from the right angle is allowed within no more than 45 °;

b) the intersection of rail tracks (railway and tram) by underground structures of the GTS should be carried out only at an angle of 90 °;

c) in gardens, parks and squares, the breakdown of routes should be carried out in the presence of a representative of the landscape gardening and green building, taking into account the least damage to green spaces.

When laying out the route for laying cables in the ground, it is necessary to observe the distances from the ground and underground structures specified in the project documentation.

When working within the security zones of underground utilities, the responsible performer of the work is obliged to instruct, against receipt, the foreman and machinists working on the mechanisms about the conditions for the production of work, show the places where underground utilities pass according to the drawings and in kind, designate the boundaries within which it is forbidden to work with the help of earthmoving mechanisms, as well as to use percussion mechanisms.

If the cable route is planned in places where there are already existing cables or other underground structures that are not accurately indicated on the street drawing, then before proceeding with the excavation of the trench, it is necessary to check the location of these structures in relation to the route. For this purpose, test holes are torn along the entire route - pits, which should have a length of 1 m along the axis of the future trench. In the event that underground structures run parallel to the future route, the pits must be dug perpendicular to its axis every 20 m. The length of each pit must exceed the width of the designed trench on each side by at least 0.3 m.

The depth of the pits, if the structures being sought are not found, must exceed the depth of the trench by 0.2 m. The pitting must be carried out in the presence of a representative of the organization operating the underground structures.

Underground structures opened during drilling and during the development of trenches must be protected by a special box and suspended in the manner indicated in the working drawings.

The route of the laid underground cable can be clarified with a special cable detector. With a cable laying depth of up to 2 m, the device determines its location with an accuracy of 10 cm and works regardless of road surfaces.

When crossing trenches with existing underground utilities, mechanized soil development is allowed at a distance of no more than 2 m from the side wall and no more than 1 m above the top of the pipe, cable, etc. The soil remaining after mechanized development is finalized manually without the use of percussion tools and with the adoption measures to prevent damage to these communications.

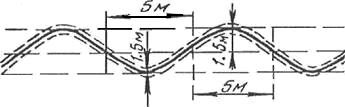

The suspension scheme of communications crossing the trench is shown in fig.

Rice. 1.14. Suspension of communications crossing the trench

a - one or more cables;

6 - cable ducts in asbestos-cement pipes;

c - pipeline;

1 - cable pipe;

2 - a box of boards or shields;

3 - log or timber; 4 - suspension-twisting;

5 - cable;

b - asbestos-cement pipes of cable ducts;

7 - I-beam; 8 - crossbars from channels;

9 - pendants made of round steel;

10 - linings;

11 - pipeline crossing the trench

The depth of the cable trench depends on where it will run.

If the cable is laid under the road on which the transport moves, then the depth of the route must be at least 1.25 meters. It is necessary to dig a trench carefully, since there may be engineering systems in the ground that are not plotted on the geo-base scheme, such an incident is very common. If the cable route runs in an urban environment, in close proximity to buildings, structures or at intersections with utilities located in the ground, digging is done only manually.

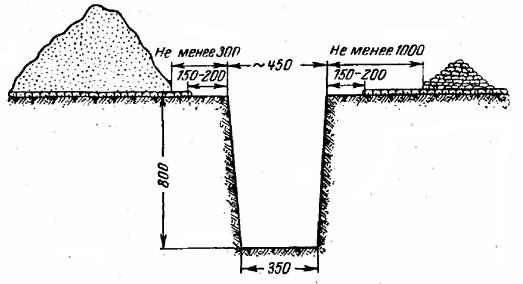

The depth of the trench should not be less than 70 cm, the width of the trench depends on the number of cables to be laid.

The depth of laying communication cables in soils of categories I-III should be at least 0.8 m, and in rocky soils - at least 0.5 m in the absence of an alluvial soil layer and 0.7 m if it is present. In settlements, the depth of the cable trench is increased to 1.0-1.2 m. The classification of soils is given in GOST 25100.

When digging a trench by hand, it is dug so that the side walls of the trench have some slope. This makes it easier to dig a trench and prevents the walls from crumbling.

The width of the trench in the upper part will depend on the angle of repose and depth; when laying one or two cables, it is taken equal to from 0.3 to 0.45 m along the bottom and, accordingly, 0.4-0.5 m along the top of the trench.

Trenches up to 1 m deep in non-caving soils can be dug without slopes.

Before digging a trench, foreign objects, temporary structures, construction debris, stones, asphalt pavements are removed from the intended route, and the area is also planned. The asphalt pavement is notched with chisels (not crowbars) along the width of the trench. If the pavement is paved with cobblestone, it is developed on each side 150-200 mm wider than the trench to prevent stones from falling into the trench, which can cause damage to workers or damage the cable laid in the trench.

For free passage of workers along the edge of the trench during excavation, the earth ejected from the trench is located on one side of the trench at a distance of at least 0.3 m from its edge, and asphalt, cobblestone and other materials - on the other side at a distance of 1 m.

When digging a trench, make sure that road signs, green spaces, etc. are not covered.

The bottom of the trench is leveled and cleaned of stones and rubble, and before rolling out and laying the cable in stony and rocky soils, it is covered with a layer of sand or loosened soil up to 10 cm thick. This layer is called the “lower bed”. Arrangement of bedding (pillow) from fine earth (sand) without stones is carried out along the entire length of the trench. To do this, along the entire trench, fine earth or sand should be prepared for backfilling the trench. In soft soils, beds can be omitted and the pipes are laid on the leveled soil of the bottom of the trench.

When digging trenches, it is necessary to ensure that the size of the torn area (especially in cities and towns) allows you to complete the work during the working day.

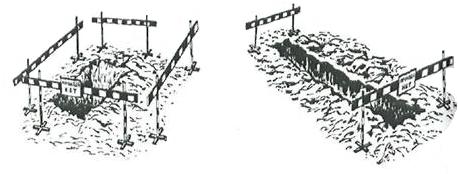

Fencing of work areas

In the course of work, a trench passing through city streets and driveways is fenced along its entire length. Warning inscriptions and signs are installed on the fences, and special lighting is installed at night and in the evening. The fences also indicate the name and telephone number of the organization performing the work. The fences are installed from the axis of the nearest rail of the tram tracks at a distance of 0.6 m, and from the railway tracks 2-2.5 m. In case of openings that require closing the passage, the direction of the detour should be clearly indicated. In places where pedestrians move, the trench is covered with temporary bridges 1 m wide made of durable boards with enclosing railings 1 m high.

Sites for earthworks in urban areas should be fenced with slingshots on portable racks, and, if necessary, or at the request of the territorial administration, with inventory boards or a blank fence. In agreement with the owner of the work site, signal plastic tapes can be used.

a) fencing of the pit and trench

b) fencing a trench dug on the sidewalk

If it is necessary to carry out earthworks on the carriageway, the organization performing these works must agree with the local traffic police on the scheme for fencing the place of work and placing road signs, indicating the types of work and the timing of their implementation. The place of work, which impedes the movement of transport, must be fenced off during the day with “quiet running” signs, and with the onset of darkness and in dense fog - with a red light signal. Light signals are installed at the ends of the trenches.

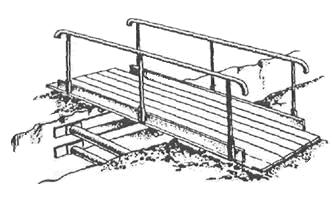

To ensure the normal passage of vehicles and pedestrians when digging streets, roads and passages over trenches, transport bridges and footbridges with railings should be installed. Transport bridges should be designed for the passage through the street of trackless vehicles with an axle load of 10 tons, and at the entrance to yards - 7 tons.

The pedestrian inventory bridge must have the following dimensions: a width of at least 0.75 m, a height with railings of -1.0 m.

The length of bridges and footbridges should cover the trench beyond the natural slope so that when they are used, the collapse of the walls does not occur.

Trenches and pits under transport bridges must be secured with spacers.

a) transport bridge

b) Footbridge

The place of work under the tram tracks must be fenced with special fences and signals installed at a distance provided for by the safety rules for the production of these works.

Prior to the start of work, it is necessary to determine the places for the passage of vehicles through the highway and the places for pedestrians to prepare in advance the required number of fences, signal signs and bridges.

If the trench crosses the passage, then first one side of the passage is torn off, pipes are laid and the trench is filled up, and then the same is done on the other side of the passage, which allows not to interrupt traffic.

Opening and restoration of road and street covers

Opening of street covers is carried out on an area determined by the size of the trenches, taking into account the norms for additional opening of covers given in the following table.

Norms for additional opening of street coverings:

When performing work in parks and squares, the upper vegetation cover is considered as a street cover.

Materials obtained from the opening of street covers, as well as other upper layers of soil, in order to avoid backfilling and clogging with soil removed from the trench, should be piled at a distance of at least 1 m from the edge of the trench on the side opposite to the soil dump.

Temporary paving of trenches on the roadway should be carried out by a construction organization performing earthworks immediately after their completion. The final restoration of street covers is carried out by specialized organizations under contracts with construction organizations.

Laying pipes in trenches

In cases where it is necessary to protect cables from mechanical damage, from the effects of aggressive soils and stray currents, they must be laid in pipes. For this purpose, steel, cast iron, asbestos-cement, ceramic and plastic pipes are used. The pipe material is determined in the project. It is allowed to replace one type of pipe with another, but this must be specified in the project.

Pipes must meet the following requirements:

- their inner surface must be smooth;

- pipe ends with inside must be rounded with a radius of at least 5 mm and not have protrusions, kinks, burrs;

- pipe connections must be strictly aligned;

- the ends of the pipes at the points of entry (exit) into the tunnels, the channels must be sealed flush with the inner surfaces of the walls.

Pipes should be laid with a slight slope of at least 0.2% (3-4 mm per 1 linear meter of pipeline) to drain condensate or water that may enter the pipeline. In areas with a sufficient natural slope, the pipeline can be buried equally along the entire length of the span. In the process of laying the pipeline, the set slope value must be controlled by a special rail with a plumb line or inclinometer.

The pipeline must also be straight horizontally. Deviation from a straight line is allowed no more than 1 cm per 1 m of pipe. To lay the pipes in a straight line, it is recommended to pull the cord on the pegs in the trench along the bottom and lay the pipes along it. Each pipe to be laid must touch the cord with its side surface, without pulling it to the side. In some cases, provided for by the project, and when unaccounted for obstacles are identified, some deviation of the route from a straight line along a smooth curve is allowed at the rate of not more than 1 cm per 1 m of pipeline length

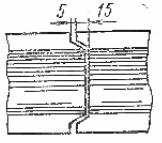

When pipes are formed into blocks, the clear distance between the pipes vertically and horizontally must be at least 10 cm. In this regard, the lower pipes of the block must be laid to a greater depth so that the upper pipes of the block are from the planning mark at a depth of 0.7 m.

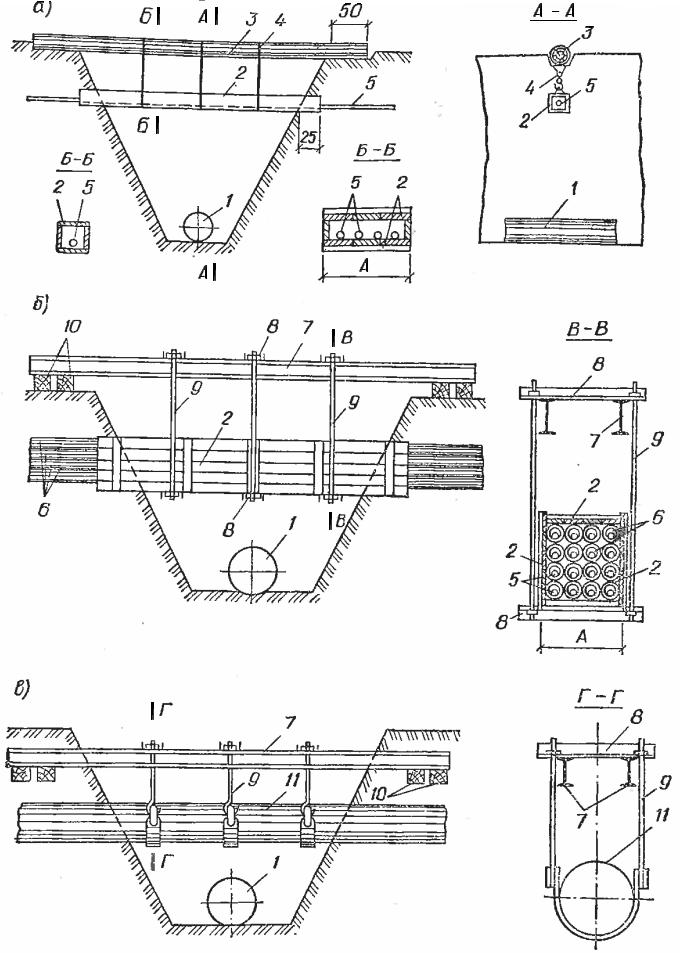

Rice. 2. Laying pipes in a trench:

1 - communication cable; 2 - brick for protection against mechanical damage; 3 - soft soil for backfilling; 4 - cables up to 35 kV; 5 - cables up to 10 kV; 6 - control cables

The width of the trench depends on the number of cables to be laid. For the convenience of installing couplings, there should be trench extensions (pit). The depth of the pit is made 10 cm deeper than the bottom of the trench.

In the event of a forced suspension of work in the middle part of the pipeline span, the channels must be temporarily closed with plugs, and the trench must be protected with earthen rollers to protect it from rain and melt water.

Methods for sealing joints when connecting pipes

Before joining the pipes, the inner and outer surfaces of the channels must be cleaned of contaminants and their ends brought together. If at the same time a discrepancy is revealed in the inner and outer diameters due to poor-quality sorting, the pipe is replaced.

Docking of pipes can be carried out in various ways.

When connecting asbestos-cement pipes, three methods of sealing joints are used:

- with the help of a cuff made of sheet steel,

- using a polyethylene sleeve,

- with the use of asbestos-cement couplings.

To seal the joints of asbestos-cement pipes in the first way, it is necessary to deliver grade 50 cement mortar (in a volume that can be used up before it dries) and sand to the trench.

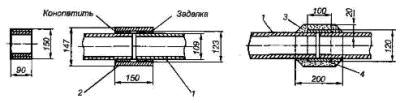

The pipes laid on the bottom of the trenches are aligned end to end. Under the joints of the ends, stepping back a little from them, soft soil is poured with a tubercle, which is rammed with light blows of the ends. The joint of the two ends is wrapped with a waterproofing tape to prevent moisture from entering the pipeline. A cuff made of sheet steel 60 mm wide is applied to the waterproofing tape (bandage), having a tongue on one side and three slots on the other. Depending on the outer diameter of the pipe, the tongue is inserted into one of the slots, tightened with pliers and bent in the opposite direction (Fig. 3).

Rice. 3. Docking of asbestos-cement pipes using a metal cuff:

1 - winding the joint with bitumen tape, 2 - lining with a metal cuff at the joint, 5 - coating the joint with cement mortar, 4 - metal cuff

The width of the applied waterproofing tape must be 20 mm greater than the width of the metal cuff. Then the entire joint is coated with cement-sand mortar grade 50.

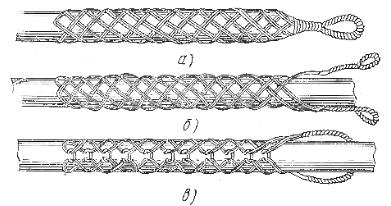

For joining asbestos-cement pipes in the second way, polyethylene couplings are used with an inner diameter to match the size of the pipe (Fig. 4).

Rice. four. Jointing of pipes with polyethylene couplings:

1 - polyethylene sleeve, 2 - pushing the sleeve onto the end of the pipe, 3 - finished joint of two pipes

After laying the pipes in the trench, their ends to the width of the coupling are wiped with a rag. It is best to put on the coupling when it is heated, for this it is lowered into water heated to boiling point and kept there for 10 - 15 minutes. Then the heated sleeve is removed from the tank with a weeding hook, shaken off and pushed onto the end of the first pipe to the protrusion in the middle of the cuff with a screwdriver, and then on the other side to the end of the second pipe to the protrusion. After the cuff cools, it narrows and fits snugly around the junction of the pipes. Since the plastic hot water become soft, the clutch is very easy to put on, you just need to do everything quickly, without letting it cool down.

If there is a high water level in the trench, then waterproofing the joint with a bituminous compound is used. The inner surface of the coupling on one side to the partition is coated with a bituminous compound and pushed onto the end of the pipe. The end of the second pipe to the width of the coupling to the partition is coated with bituminous compound and injected into the coupling until docking. Sealing the joint is performed in the same way as described earlier.

In some cases, the joints of asbestos-cement pipes are sealed with asbestos-cement couplings, the inner diameter of which is larger than the outer diameter of the pipe. The gap between the pipe and the coupling is clogged with resin tow and sealed with cement mortar or bituminous mastic.

Concrete pipes are interconnected by inserting the protrusion of one pipe into the socket of the other (Fig. 5). A belt of grade 50 cement mortar is applied around the joint. When sealing the joints of asbestos-cement and concrete pipes, cement mortar must be coated not only from above, but also from below the pipeline in order to avoid leakage and deterioration of the strength of the pipeline. For better setting of the cement mortar with pipes, their joints are moistened with water before sealing.

Rice. 5. Jointing of concrete pipes

Preparing channels for cable laying

Often there are cases when, as a result of groundwater penetration into the canal, the canals in some places are filled with sand, clay, silt, etc., while the canals must be cleaned. For cleaning, special steel scoops screwed onto the end of the head stick should be used. The litter is loosened by blows with the pointed edge of the scoop and the scoop filled with it is removed from the channel. The scoop collects dirt, then it is pulled back, cleaned and pushed into the channel again. The operations are repeated until the sticks freely pass through the channel. Residual dirt is removed with a steel brush.

Rice. 6.- Scoop for cleaning clogged channels

If cleaning the channels does not give positive results, then this section of the sewer should be opened and repaired. If necessary, inserts are made from segments of new solid or vertically cut pipes.

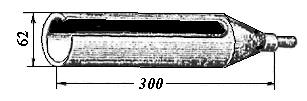

The serviceability of the cable channels of the pipeline is checked by dragging a test cylinder through each channel. To do this, the test cylinder is connected with a carabiner to a metal brush and pulled through the channel to align and smooth the walls of the channels at the junction of the pipes and clean the cavity of the pipes from litter. At the ends of the trial cylinder and the brush there are lugs to which a cable is tied on both sides, so that if the cylinder stops, it can be pulled back if the channel is badly clogged.

Rice. 7. Trial cylinder

Rice. eight.- Canal cleaning brush

The cable pipeline is checked before putting it into operation. After checking the serviceability, plastic plugs are installed on all channels to prevent clogging and penetration of gases at the ends of the laid section, which prevents sand, stones and other debris from entering the pipe, which can damage the cable during its installation. Instead of installing a plug, the ends of the pipe can simply be foamed with mounting foam.

The further electrical installation of the cable into the laid pipes depends on how you prepared the cable route and laid the pipes. If you poorly compacted the sand or docked the pipes poorly, laying the cable will be very problematic, since when pulling the cable into the pipes, it can be difficult to pass through and lead to cuts in the insulation

cable.

Download recommendations for the use of asbestos-cement pipes - To read the hidden text you need to log in or register.

Transporting the cable and preparing it for laying

Properly organized transportation of cables guarantees their safety and, consequently, the durability of cable lines.

Within the storage areas, the drums are rolled (over a distance of not more than 100 m) manually, while both ends of the cable are securely attached to the drum.

Cable drums are rolled in the direction of cable winding, indicated by an arrow on the drum. Violation of this rule causes a weakening of the cable winding on the neck of the drum and unraveling of the coils, and, consequently, their pinching or sinking during rolling.

The delivery of cables and materials (pipes, blocks, etc.) to the place of work is carried out, as a rule, before the start of work. When transporting or moving reels with cable, care must be taken to prevent damage to the reel and cable.

Before transportation and laying, cable drums are subjected to a check, which begins with an external inspection, the integrity of the drum sheathing, the bolts fastening the drum, the sealing of the cable ends and the safety of the metal bushings (near the hole) on the cheeks of the drum, the factory marking on the outside of the cheek of the drum and the passport cable, termination of cable ends. The results of the inspection are documented in an act, which is subsequently attached to the executive documentation of the cable line.

Cables that have not passed input control are not subject to laying.

In order to avoid possible damage to the cable, cable drums must not be thrown off the car, cable trolleys, conveyors.

It is recommended to store them under a canopy. It is allowed to store the cable in the open air (for up to 1 year) in drums sheathed with boards. Plastic-insulated cables without an outer sheath in unwired drums should not be stored outdoors. They should be stored with hermetically sealed ends.

To protect the lower part of the drum from possible flooding during rains, the drums are mounted on wooden linings.

Transportation, unloading and movement of drums with cable is carried out only in a vertical position.

Cable testing and measurement before laying and installation

Before laying the cable, the insulation resistance of the cores is measured, and for communication cables, the insulation resistance is measured and the cores are checked for a break and they are connected to each other and to the metal sheath, since during transportation and reloading of the cable to the object, the cable insulation may already be damaged, and you will carry out the wiring of the damaged cable into the pipes, and then you have to look for the place of the cable damage.

To check the cores for a break and for their communication with each other and with a metal sheath, both ends of the cable on the drum are released over a length of 80-300 mm from protective coatings and a metal sheath. Then, insulation is removed from all the cores of one end of the cable over a length of 1.5-3 cm, the stripped cores are connected to each other and to the metal sheath using copper wire. The cores of the second end of the cable are cut into the so-called pyramid, which is obtained as a result of the fact that the cores of each subsequent layer are cut 15-20 mm shorter than the previous one.

When checking the cores for communication between themselves and with the cable sheath, one pole of the battery with a voltage of 3.0-4.5 V is connected to the cable sheath (Fig. 1, a), and on the other - through telephone 3 in series with each of the cable cores, previously disconnecting it for the duration of the test from the common beam. If the tested core has a connection with any other core or with a metal sheath, then a click is heard in the phone under the action of the battery current according to the scheme: battery pole, cable sheath 2, tested core, telephone and another battery pole.

To test the wires for a break, all the wires are attached to the sheath and the test is carried out from the side of the pyramid. When you touch the test core of the free end of the wire coming from the telephone, a click should again be heard in the latter. If the click does not appear on the phone, then the tested core is broken.

Rice. 9. Scheme for checking the cable for breakage (a) and message (b)

When testing the wires for breakage and communication, it should be borne in mind that with a long cable length, a click in the telephone (weaker) can be obtained due to a noticeable electrical capacitance between the wires and between the wires and the sheath. Therefore, with a long cable length, it is advisable to replace the phone with some other device (ammeter, voltmeter).

The detected faulty strands are checked again, and then separated from the bundle and tied up. A list of all damaged strands is compiled, indicating the number of the pair of strands, the layer in which it is located, and the nature of the damage.

Electrical checks of cables in a plastic sheath are performed in a similar way, only in the circuit, instead of a metal sheath, a bare copper core is used as a "ground".

To control the insulation of cable cores, its resistance is measured with cable devices or megohmmeters. The data obtained is compared with the normative insulation resistance for a particular cable at a temperature of 20ºС. The insulation resistance of the measured cable is considered satisfactory if it is equal to or greater than the standard.

Measuring the insulation resistance of cores and testing them for breakage at signal and control cables is carried out using a megohmmeter.

The cutting of the cable for measurements using a megohmmeter is carried out in the same way as when measuring the connection between the cores and the breakage of the cores. When measuring the core insulation, one conductor connected to the terminal L of the megohmmeter is connected to the core under test, and the other conductor is connected to terminal 3 with a metal sheath or with the rest of the cores interconnected (for cables with a plastic sheath). By rotating the handle of the megohmmeter with a frequency of about 130 rpm, the value of the insulation resistance of the core is counted on its scale. Depending on the type of megohmmeter, they can measure the value of insulation resistance up to 500-1000 MΩ. When testing with a megohmmeter, the core was broken, if the core being tested does not have a break, then when the handle of the megger is rotated, the arrow of its device will remain at zero. In the event of a break, the arrow will deviate to the left, indicating the amount of high resistance, which will indicate the presence of a broken core.

At the end of the electrical tests, the cable cores are cut off and the metal sheath of both ends of the cable is sealed on the drum; the ends of cables with a non-metallic sheath are carefully insulated with PVC tape or in another way to prevent moisture from entering the cable.

When loading drums, as well as when rolling them on the ground, it is necessary to ensure that the direction of rotation of the drum coincides with the direction of the arrow on the cheek of the drum.

Cable laying in the ground

High quality, stable and reliable operation of the constructed cable lines can be ensured if the technology of their laying is observed.

All electrical work on laying the cable in the trench must be carried out in accordance with the PUE and PTEEP, since compliance with the rules and regulations is the key to trouble-free operation of the power system, electrical wiring, electrical installations and electrical equipment.

Prior to the laying of cable lines, construction work on the construction of routes must be fully completed. For example, before laying cables in the ground, a construction company completes the digging of trenches, the installation of inputs and intersections.

Pulling must be carried out taking precautions so as not to damage the cable sheath on the edge of the pipe (the edges must be pre-rounded and not have sharp edges or burrs).

The further electrical installation of the cable into the laid pipes depends on how you prepared the cable route and laid the pipes. If you have poorly compacted the sand or poorly joined the pipes, laying the cable will be very problematic, since when pulling the cable into the pipes, it can be difficult to pass it and lead to cuts in the cable insulation.

For the production of work on the construction of cable lines, the installation organization is provided with technical documentation, including a working draft with a cable route plan and the necessary cuts. In the plans and drawings of the longitudinal profiles of the route, all intersections of the designed cable line with other underground structures are indicated, regardless of their depth. For complex transitions, special drawings are made or links are given to standard albums.

The installation organization is also issued with construction drawings of cable structures indicating all embedded parts. Particularly important documents are the cable magazine, specifications for cables, couplings, materials, and estimates.

The projects are handed over to the installation organization with a stamp “for production”, agreed with the city architecture services, construction departments, land users, the energy system and all organizations whose underground communications are located in the area of the designed cable lines.

For difficult laying conditions, the project for the production of works (PPR) is carried out by the design organization, and for normal conditions - by the installation organization. A more detailed list of project documentation required for the execution of works is indicated in the special literature.

When laying cables, a number of technological operations can be distinguished, which are subject to special control in order to improve the quality of work and increase the reliability of the installed cable lines.

Most often, cable damage occurs when the technology of their laying is violated:

- in case of non-compliance with the distances between cables laid in parallel, between cables and underground structures;

- non-compliance with the depth of their laying;

- winding cables from drums, pulling cables with a force exceeding the permissible loads;

- in case of unacceptable bends and twists of cables; low ambient temperatures.

When laying several cables in parallel, the minimum distances established between them are observed according to the conditions of mutual permissible heating or possible damage to the cables by an arc in the event of a short circuit on one of these cables.

Laying cables to a shallow depth increases the possibility of mechanical damage during various earthworks near cable lines. During the rolling of cables from drums, they may be damaged as a result of sticking to each other of tightly packed coils. The rapid rotation of the drums in this case leads to jerks and breaks in the cables. Therefore, the cable unwinding is performed at a minimum speed, using various devices for braking rotating drums. Damage can occur due to falling coils when the cable is wound on the drum incorrectly (usually when rewinding the cable onto inventory drums at cable sites) or violating the rules for rolling drums. In this case, the coil descending from the drum is pinched by adjacent coils. In this case, when unwinding the cable, the drum is temporarily stopped and the jammed coil is released.

Damage to cables is possible after laying them with unacceptable bending radii and twisting when unwinding manually with loops.

All these operations must exclude violations of the installation technology and be carried out under the supervision of experienced foremen or engineering and technical workers.

When laying cables in a trench along the entire length, a slack in the form of a “snake” is provided to compensate for changes in the length of the cables caused by temperature fluctuations in them during operation. The length of the cable in this case is 2-3% more than the length of the trench.

Near the pits for couplings, during laying, reserves of the ends of the construction lengths of cables are left. Reserves of cables are provided for compensators that protect the couplings from damage when the soil is displaced, as well as from temperature deformation of the cables.

Before proceeding with laying the cable, stones, debris and excess objects are removed from the trench, water is pumped out, etc. After that, the bottom of the trench is leveled and a “bed” of sand or fine earth 100 mm thick is made. At the same time, the device of passages through the wall of buildings is performed.

To install the cable in pipes, it is required to use a special elastic steel cable, with which the cable is pulled through the pipes.

First, the cable is pulled into the pipe so that it passes through it and exits from the other side of the cable route by 10 - 15 meters, because with the help of this cable the cable is installed into the pipes.

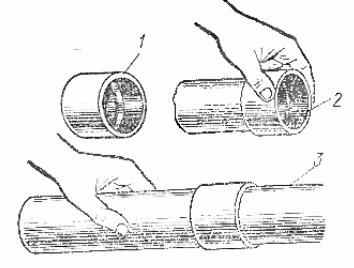

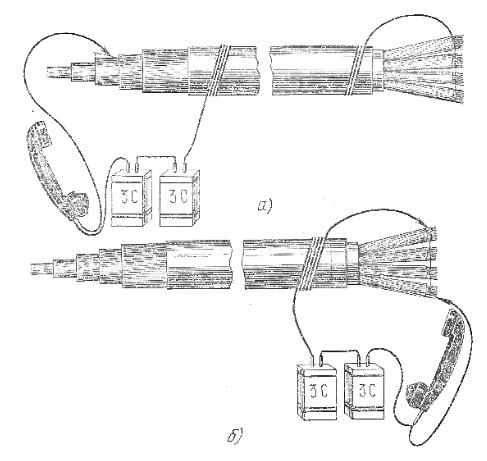

To attach the cable to the cable, you will need a special metal stocking, which is a cylinder woven from thin steel wires and having ducks on one side for attaching it with a rope or cable. When put on, the stocking expands and easily slides over the cable sheath, and when pulled, it contracts, tightly embracing the cable.

Metal cable stockings are made of three types: end - for termination at the end of the cable, through (open at both ends) - for pulling the cable and the well to the desired length and split - for fastening at any point of the cable.

Fig.10. Cable steel stockings: a) - end, b) - through, c) - split.

For more reliable fastening of the stocking with the cable, screws are screwed into the stocking pulled over the cable sheath or the end of the stocking is tied up with soft wire, and then wrapped with insulating tape over the knitting.

If the cable is laid along an occupied channel, then it is connected to a hemp rope, and the cable stocking is wrapped with two or three layers of insulating tape along the entire length, which protects the cable in the channel from scratches and chafing. A cable with a capacity of up to 100 pairs is pulled into the sewer by hand.

It is necessary to pull the cable by the cable laid in the pipes very carefully so as not to damage the cable sheath. If, when pulling the cable, it ran into an obstacle and does not go further, then you should not tie the cable to a car or tractor, since instead of a cable you can pull out bare wires that will only be suitable for delivery to a non-ferrous metal collection point. If the cable does not go through, then you should gently pull it back and try to pull it out again.

After you have pulled the cable through the pipes, you must definitely carry out repeated electrical measurements, measurement of insulation resistance electrical circuits both between all cores of the cable, and between each core and metal protective sheath of the cable (between each core wire or cable in a non-metallic sheath and a pipe, duct, tray, structure) to make sure that you do not damage the insulation when laying the cable through pipes

Measuring the insulation resistance of electrical wiring (measurement, control, power, signaling circuits, etc.) is carried out with a megger for a voltage of 1000 V. The insulation resistance must be at least 0.5 MΩ. The duration of the test voltage application is 1 min. Based on the results of the insulation resistance test, an act is drawn up. The funnels that you installed on the pipes before laying the cable need to be foamed with mounting foam. This must be done so that when digging in the trench, sand and stones do not get into the pipes and rodents do not penetrate into the pipes.

Upon completion of the cable laying, the trench is checked for compliance with the project requirements. At the same time, an external inspection of the condition of the cable and a check for the correct termination of its ends are carried out. Before filling the trench with soil, permanent landmarks (buildings, fences) are identified and an executive drawing of the route of the laid cable lines is drawn up. On the executive drawing, the locations of the cable line are fixed in relation to permanent landmarks in the area, their intersections with roads and underground utilities, sections of cables laid in pipes or at a depth of more than 1 m are marked, as well as the locations of connecting and branch couplings. In the absence of local permanent landmarks (in open areas or outside the city), reinforced concrete or metal relay poles are installed on the cable route at a distance of 100-150 m from one another on straight sections of the route, as well as on the turns of the route and at the couplings.

In addition to the route of the laid cable, other underground and above-ground structures are applied to the plan, for example, water and gas pipelines crossing the cable and running parallel, other cables, roads, ditches, etc., located in a strip of 20-30 m from the cable.

Drawing up an executive plan facilitates the further operation of the cable and allows you to more accurately and quickly determine the location of its damage.

On laid cables, as well as on all couplings and terminations, tags are strengthened. Cable tags indicate voltage, brand, section, number or name of the cable. On the tags of the couplings and terminations - the section, the date of cutting and the name of the cableman.

After laying the cable in the trench, leveling it and tying it to the landmarks, sprinkle it on top with a layer of sand or fine earth 100 mm thick. Powdering the cable with soil containing construction waste, brick, slag, etc. is not allowed.

Backfilling of trenches with soil is carried out in succession in separate layers with a thickness of not more than 0.2 m, and each layer is carefully compacted with rammers with watering. Within the carriageway of streets, roads and squares with an improved coating, trenches are backfilled only with sand in order to avoid precipitation of the coating after restoration.

Before backfilling the trench, the laid pipeline must be carefully examined by the foreman (foreman) with the participation of the customer's representative, and its compliance with the technical requirements must be recorded by an act for hidden work. Before commissioning, the patency of the channels must be checked with a test cylinder.