What is the voltage in the wires of the electric train. History of railway electrification

With the development of industry and Agriculture countries, the amount of goods that needs to be transported from one region of the country to another increases, and this imposes requirements on railway transport to increase the carrying and throughput capacity railways. In our country, more than half of the total cargo turnover is mastered by electric traction.

There were no electric railways in Tsarist Russia. The electrification of the main highways was planned in the first years of Soviet power during the organization of the country's planned economy.

In the GOELRO plan developed in 1920, attention was paid to increasing the carrying and throughput capacity of railways by transferring them to electric traction. In 1926, the Baku-Surakhani line was electrified with a length of 19 km at a voltage of contact network 1200 VDC. In 1929, the suburban section Moscow - Mytishchi, 17.7 km long, with a voltage of 1500 V in the contact network, was switched to electric traction. current. After that, the electrification of some of the most severe in terms of climatic conditions, the most traffic-intensive sections and lines with a heavy profile, began.

By the beginning of World War II, the most difficult sections in the Caucasus, the Urals, Ukraine, Siberia, the Arctic and the suburbs of Moscow with a total length of about 1900 km were transferred. During the war, lines were electrified in the Urals, in the suburbs of Moscow and Kuibyshev with a total length of about 500 km.

After the war, sections of electrified railways in the western part of the country, located on the territory temporarily occupied by the enemy, had to be restored. In addition, it was necessary to transfer new heavy sections of railways to electric traction. Suburban sections, previously electrified at a voltage of 1500 V in the contact wire, were transferred to a voltage of 3000 V. Starting from 1950, from the electrification of individual sections, they switched to transferring entire freight-intensive directions to electric traction and work began on the lines Moscow-Irkutsk, Moscow -Kharkov, etc.

The increase in the flow of national economic goods and the growth of passenger traffic require more powerful locomotives and an increase in the number of trains. At a voltage in the contact network of 3000 V, the currents consumed by powerful electric locomotives, with a significant amount of them in the power supply zone from traction substations, caused large energy losses. To reduce losses, it is necessary to put traction substations closer to one another and increase the cross section of the wires of the contact network, but this increases the cost of the power supply system. It is possible to reduce energy losses by reducing the currents passing through the wires of the contact network, and in order for the power to remain the same, it is necessary to increase the voltage. This principle is used in the electric traction system of alternating single-phase current of industrial frequency of 50 Hz at a voltage in the contact network of 25 kV.

The currents consumed by the electric rolling stock (electric locomotives and electric trains) are much less than with a direct current system, which makes it possible to reduce the cross section of the wires of the contact network and increase the distances between traction substations. This system in our country began to be explored even before the Great Patriotic War. Then, during the war, research had to be stopped. In 1955-1956. according to the results of post-war developments, the experimental section of the Necklace-Pavelets of the Moscow road was electrified using this system. In the future, this system began to be widely introduced on the railways of our country, along with a direct current electric traction system. By the beginning of 1977, electrified lines in the USSR stretched for a distance of about 40 thousand km, which is 28% of the length of all railways in the country. Of these, about 25 thousand km are on direct current and 15 thousand km are on alternating current.

Railways from Moscow to Karymskaya with a length of over 6300 km, from Leningrad to Yerevan - about 3.5 thousand km, Moscow-Sverdlovsk - over 2 thousand km, Moscow-Voronezh-Rostov, Moscow-Kyiv-Chop, lines connecting the Donbass with the Volga region and with the western part of Ukraine, etc. In addition, the suburban traffic of all large industrial and cultural centers has been switched to electric traction.

In terms of the rate of electrification, the length of lines, the volume of traffic and cargo turnover, our country has left far behind all the countries of the world.

intensive railway electrification due to its great technical and economic advantages. Compared to a steam locomotive or with the same weight and dimensions, it can have significantly more power, since it does not have a primary engine (steam engine or diesel engine). Therefore, the electric locomotive provides work with trains at much higher speeds and, consequently, increases the throughput and carrying capacity of railways. Using the control of several electric locomotives from one post (a system of many units) allows you to increase these figures to an even greater extent. Higher travel speeds provide faster delivery of goods and passengers to their destination and bring additional economic benefits to the national economy.

Electric traction has a higher efficiency than diesel traction and especially steam traction. The average operational efficiency of steam traction is 3-4%, diesel locomotive - about 21% (with 30% use of diesel power), and electric traction - about 24%.

When an electric locomotive is powered by old thermal power plants, the efficiency of electric traction is 16-19% (with the efficiency of the electric locomotive itself being about 85%). Such a low efficiency of the system with a high efficiency of an electric locomotive is due to large energy losses in furnaces, boilers and turbines of power plants, the efficiency of which is 25-26%.

Modern power plants with powerful and economical units operate with an efficiency of up to 40%, and an efficiency of up to 40%. electric traction when receiving energy from them is 25-30%. The most economical operation of electric locomotives and electric trains is when the line is powered by a hydroelectric power station. At the same time, the efficiency of electric traction is 60-62%.

It should be noted that steam locomotives and diesel locomotives operate on expensive and high-calorie fuel. Thermal power plants can operate on lower grades of fuel - brown coal, peat, shale, and also use natural gas. The efficiency of electric traction also increases when the sections are powered by nuclear power plants.

Electric locomotives are more reliable in operation, require lower costs for equipment inspections and repairs, and allow increasing labor productivity by 16-17% compared to diesel traction.

Only electric traction has the properties to process the mechanical energy stored in the train into electrical energy and transfer it during regenerative braking to the contact network for use by other electric locomotives or motor cars operating in the traction mode during this period. In the absence of consumers, energy can be transferred to the power system. Due to energy recovery, it is possible to obtain a large economic effect. Thus, in 1976, about 1.7 billion kWh of electricity was returned to the grid due to recuperation. Regenerative braking makes it possible to increase the level of train traffic safety, reduce the wear of brake pads and wheel rims.

All this makes it possible to reduce the cost of transportation and make the process of transporting goods more efficient.

Due to the technical reconstruction of traction in railway transport, approximately 1.7 billion tons of fuel were saved, and operating costs decreased by 28 billion rubles. If we assume that until now steam locomotives would work on our highways, then, for example, in 1974 it would be necessary to use up one third of the coal mined in the country in their furnaces.

Electrification of Russian Railways contributes to the progress of the national economy of the surrounding areas, since industrial enterprises, collective farms, state farms receive power from traction substations and inefficient, uneconomical local diesel power stations are closed. Every year, over 17 billion kWh of energy goes through traction substations to supply non-traction consumers.

With electric traction, labor productivity increases. If with diesel traction labor productivity increases by 2.5 times compared with steam, then with electric traction it increases by 3 times. The cost of transportation on electrified lines is 10-15% lower than with diesel traction.

Railway electrification

There are more than 100,000 km of electrified railways all over the world today. The most rapidly electrification was carried out in our country until 1990.

The birthday of electric traction is considered to be May 31, 1879, when the first 300 m long electric railway built by Werner Siemens was demonstrated at the industrial exhibition in Berlin (Fig. 20). Electric locomotive, reminiscent of a modern electric car,

Rice. 20. The first electric railway

powered by a 9.6 kW (13 hp) electric motor. Electric current with a voltage of 160 V was transmitted to the engine along a separate rail, the rails along which the train moved - three miniature trailers at a speed of 7 km / h served as a return wire.

In the same year, 1879, an internal electric railway line with a length of about 2 km was launched at the Duchen-Fourier textile factory in Breuil, France. In 1880 in Russia, F.A. Pirotsky managed to set in motion a large heavy car with a capacity of 40 passengers by electric current. On May 16, 1881, passenger traffic was opened on the first urban electric railway Berlin - Lichterfeld. The rails of this road were laid on a flyover. Somewhat later, the Elberfeld-Bremen electric railway connected a number of industrial centers in Germany.

As you can see, initially electric traction was used on city tram lines and industrial enterprises especially in mines and coal mines. But very soon it turned out that it was profitable on the pass and tunnel sections of railways, as well as in suburban traffic. In 1895, the tunnel in Baltimore and tunnel approaches to New York were electrified in the USA. Electric locomotives with a capacity of 185 kW (50 km/h) have been built for these lines.

After World War I, many countries embarked on the path of electrification of railways. Electric traction is beginning to be introduced on main lines with high traffic density. In Germany, the lines Hamburg-Alton, Leipzig-Halle-Magdeburg, the mountain road in Silesia, the Alpine roads in Austria are being electrified. Electrifies northern roads Italy. France and Switzerland are starting to electrify. In Africa, an electrified railway appears in the Congo.

In Russia, there were projects for the electrification of railways even before the First World War. The electrification of the St. Petersburg - Oranienbaum line has already begun, but the war prevented its completion. And only in 1926 the movement of electric trains between Baku and the Sabunchi oil field was opened. On October 1, 1929, regular movement of electric trains began on the Moscow-Mytishchi section.

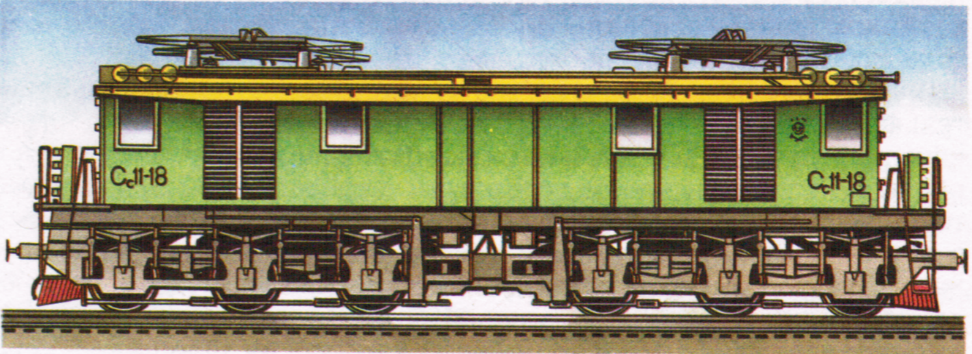

On August 16, 1932, the first in the USSR main electrified section Khashuri - Zestafoni was put into operation, passing through the Surami pass in the Caucasus. In the same year, the first domestic electric locomotive of the C series was built (Fig. 21). In the 1930s, separate sections with a large freight traffic and a heavy track profile were electrified, such as Kizel - Chusovskaya, Goroblagodatskaya - Sverdlovsk, Kandalaksha - Murmansk and a number of others. By the beginning of 1941, the total length of electrified lines exceeded 1800 km. Electrification did not stop even during the Great Patriotic War.

Rice. 21. The first Soviet electric locomotive of the C series with

The technique of electric railways has changed radically during their existence, only the principle of operation has been preserved. The locomotive axles are driven by electric traction motors that use the energy of power plants. This energy is supplied from power plants to the railway through high-voltage power lines, and to electric rolling stock through a contact network. The return circuit is the rails and the ground.

Three different electric traction systems are used - direct current, alternating current reduced current of low frequency and alternating current of standard industrial frequency of 50 Hz. In the first half of the current century until the Second World War, the first two systems were used, the third received recognition in the 50-60s, when the intensive development of converter technology and drive control systems began. In the DC system, the current collectors of the electric rolling stock are supplied with a current of 3000 V (in some countries 1500 V and below). Such a current is provided by traction substations, where alternating current high voltage of general industrial power systems is reduced to the desired value and rectified by powerful semiconductor rectifiers.

The advantage of the DC system at that time was the possibility of using DC collector motors with excellent traction and operational properties. And among its disadvantages is the relatively low voltage value in the contact network, limited valid value motor voltages. For this reason, for contact wires significant currents are transmitted, causing energy losses and hindering the process of current collection in contact between the wire and the current collector. The intensification of rail traffic, an increase in the weight of trains led to difficulties in powering electric locomotives in some sections of direct current due to the need to increase the cross-sectional area of the wires of the contact network (suspension of a second reinforcing contact wire) and ensuring the efficiency of current collection.

The entire DC system has become widespread in many countries, more than half of all electrical lines operate on such a system.

The task of the traction power supply system is to ensure the efficient operation of electric rolling stock with minimal energy losses and at the lowest possible cost for the construction and maintenance of traction substations, contact networks, power lines, etc.

The desire to raise the voltage in the contact network and exclude the rectification process from the power supply system explains the use and development in a number of European countries (Germany, Switzerland, Norway, Sweden, Austria) of an alternating current system with a voltage of 15,000 V, which has a reduced frequency of 16 2 / 3 Hz . In this system, electric locomotives use single-phase commutator motors having worse performance than DC motors. These motors cannot operate at the common industrial frequency of 50 Hz, so a reduced frequency must be applied. To generate electric current of this frequency, it was necessary to build special "railway" power plants that were not connected with general industrial power systems. The power lines in this system are single-phase, at substations only voltage reduction by transformers is carried out. Unlike DC substations, in this case, AC-to-DC converters are not needed, which were used as unreliable, bulky and uneconomical mercury rectifiers. But the simplicity of the design of DC electric locomotives was of decisive importance, which determined its wider use. This led to the spread of the direct current system on the railways of the USSR in the early years of electrification.

In the post-war period, power supply devices dismantled during the war years were restored, and electrification of lines with high traffic density was continued.

The pace of electrification increased sharply after the adoption by the government in 1956 of the resolution "On the General Plan for the Electrification of Railways." By 1980, the length of sections operating on electric traction amounted to 32.8% of the total length, and the volume of traffic performed by them was equal to 54.8%.

In the first decades, railways were electrified at a constant current of 1500 V (suburban sections) and 3000 V (main lines). To connect sections with different voltages in the contact network, special electric locomotives (VL19) and multiple unit electric sections (SR) were built, transformers for mercury rectifiers were created that can operate at two voltages: 1650 and 3300 V. Subsequently, all sections with a voltage in the contact network of 1500 V transferred to 3000 V. In the 50s, a more powerful eight-axle DC electric locomotive VL8 was created, and then - VL10 and VL11.

Since the 1930s, the possibilities of using single-phase alternating current of industrial frequency for traction purposes have been studied. The ongoing research was resumed in 1951. As an experimental one in 1955 - 1956. on alternating current with a voltage of 22 kV, the section Ozherelye - Pavelets, 137 km long, was electrified. The electric rolling stock and the alternating current traction power supply system were tested on it, the first station for joining the contact network of two types of current was created.

In this system, traction substations, as in the DC system, are powered by general industrial high-voltage three-phase networks. But they do not have rectifiers. The three-phase alternating current voltage of power transmission lines is converted by transformers into a single-phase contact network voltage of 25,000 V, and the current is rectified directly on the electric rolling stock. Lightweight, compact and safe for personnel, semiconductor rectifiers, which replaced mercury ones, ensured the priority of this system. All over the world, railway electrification is developing according to the industrial frequency alternating current system.

The first to be electrified on alternating current with a voltage in the contact network of 25 kV in 1960 was one of the most heavily loaded sections of the East Siberian Railway, Mariinsk - Zima with a heavy track profile, located in an area with harsh climatic conditions.

In addition to the traditional 25 kV alternating current system, its varieties have been and are being used: with suction transformers (to reduce the cost of protecting communication lines from the electromagnetic influence of the contact network), with a longitudinal wire with a voltage of 50 kV and autotransformers (the so-called 2x25 kV system), with shielding reinforcing wire (to reduce the resistance of the traction network).

Since 1956, electric traction has been put into operation mainly on the main long-distance freight traffic routes connecting the European part of the country with the Urals and Siberia, including its eastern part, as well as with the south of the country. In 1961, the electrification of the world's largest highway Moscow - Baikal with a length of 5647 km was completed, in 1962 - the highway Leningrad - Leninakan with a length of 3500 km. The electrification of entire areas has significantly improved the use of electric locomotives.

For new lines, electrified on alternating current with a frequency of 50 Hz, a voltage of 25 kV, six-axle VL60 electric locomotives with mercury rectifiers and collector motors were created, and then eight-axle ones with VL80 and VL80 semiconductor rectifiers. VL60 electric locomotives were also converted to semiconductor converters and received the designation of the VL60 k series.

The new electric rolling stock, compared to the one that was produced 20-30 years ago, has changed a lot structurally and externally. Eight-axle VL80 r and 12-axle VL85 (Fig. 22) AC electric locomotives have been created, which are distinguished by high traction and braking characteristics due to smooth regulation of traction force and speed, automatic control and high energy characteristics. Production of 12-axle DC electric locomotives has begun.

Rice. 22. AC locomotive VL85

Thyristor, or so-called impulse, regulators have successfully replaced the outdated system of stepped rheostat regulation. In many countries, they have completely switched to the production of DC electric rolling stock with thyristor converters.

In connection with the development of semiconductor converter technology, collector motors are increasingly being replaced by AC motors, asynchronous and synchronous.

On modern electric locomotives, automation of control and optimization of modes using microprocessor technology are widely used. Onboard and stationary equipment diagnostics are being introduced. The equipment for protection against short-circuit currents and overvoltages is being improved.

Electric traction is the most economical way of transporting goods in terms of fuel consumption. To move 1 ton of cargo per 100 km, 1 kWh of electricity is consumed. In 1998, the share of electricity consumed by rail transport in the structure of electricity consumption according to the Ministry of Fuel and Energy of the Russian Federation was only 4.7%. Electric locomotives have an undeniable advantage - they are capable of generating and returning electrical energy to the traction network during regenerative braking. In 1998, due to regenerative braking, the annual energy savings amounted to approximately 0.7 billion kWh, i.e., 3.2% of its consumption for train traction. Electric traction is the most environmentally friendly mode of transport.

With the development of technology, contact network devices and traction substations were improved. Reinforced concrete supports on block foundations, rigid crossbars, compensated suspensions, allowing a speed of 200 - 250 km / h, are widely used. For the AC contact network, reinforced concrete inseparable supports of the CC type are used, and, if necessary, separate ones with foundations of increased reliability.

At traction substations, instead of mercury rectifiers, which replaced motor generators, powerful power semiconductor converters operate. Almost all electrified lines are telemechanized. The first telecontrol systems were relay-contact, then they were replaced electronic devices and, finally, systems based on integrated circuits and microprocessors.

A catenary type KS-200 was installed on the St. Petersburg - Moscow line, which ensures reliable current collection at a train speed of up to 200 km/h.

In recent years, the electrification range with a service life of 40 years or more has been steadily increasing. Its length in 2000 was 8900 km, or 22%. In 2005, it exceeded 15 thousand km. The specific damage to the contact network, which has served for 40 years or more, is 2.7 times higher than in newly commissioned sections. Maintenance of technical means in working condition only by overhaul of their individual elements not only does not improve the performance of the entire system, but also limits the possibility of increasing the carrying capacity of sections. New technical solutions and updating of technical means of power supply are needed.

In the context of an increase in the length of electrified lines, the service life of which has reached the limit, it is necessary to ensure the strengthening of the material and technical base of the economy of electrification and power supply in order to stabilize the technical condition, and the main main directions of the network - to improve the main technical and operational indicators of the traction power supply system: contact network, traction substations, non-traction power supply networks (0.4-10 kV).

The improvement of technical means should be aimed at creating intelligent automatic control systems that provide optimal operating modes for power supply devices.

With regard to the contact network, it is necessary:

Equip laboratory cars for testing the contact network with computer-based diagnostic complexes that allow checking the nodes and elements of the contact suspension for heating, monitoring the health of insulators, assessing the wear of the contact wire with an analysis of its condition, as well as the quality of the current collection, etc .;

Develop technical solutions aimed at reducing damage to contact network supports, supporting devices, fittings, insulators;

Create a self-adjusting contact suspension for high-speed traffic areas.

To improve the reliability of traction substations, it is required to develop and implement the following devices:

Step-down and traction transformers of new types;

Switches with new electrically insulating environmentally friendly fillers (SF6, midsection); vacuum switches;

Rectifier and rectifier-inverter converters on new generation power electronic devices;

Powerful energy storage.

When constructing power supply devices, it is necessary to use complete prefabricated devices, modules and blocks of high prefabrication.

In recent years, a lot of research has been done in the world on all the pros and cons of electrification. All researchers acknowledge that electrification is economically beneficial. The conclusions of these works diverge only with respect to the amount of return on invested capital. According to various estimates, the amount of profit exceeds 14%.

The first possibilities of equipping the railway with electric traction were discussed in 1874. Russian specialist F.A. Pirotsky in the indicated period of time carried out the first practical experiments on the railway tracks near Sestroretsk on the possibility of transmitting electrical energy through the use of rails isolated from the ground.

The first attempts to equip electric traction

The work was carried out at a distance of one kilometer. The second rail served as a return wire. The resulting electrical energy was supplied to a small engine. Two years later, after the start of the ongoing work, specialist F.A. Pirotsky publishes an article on the results obtained in one of the technical engineering journals. The end result was that he tested the start-up of trolleys moving with the help of the received electricity along the iron tracks.

First practical application

Werner Siemens, who lives in Germany, has implemented the practical application of electricity on the railway. The Berlin Industrial Exhibition of 1879 exhibited this achievement on its premises in the form of a narrow gauge railway, on which the guests of the exhibition had the honor to pass. The train set consisted of several open-type cars pulled by an electric locomotive. The movement was provided by two motors powered by direct current, the voltage of one hundred and fifty volts was given by an iron strip located in the inter-rail space. One of the running rails served as a return wire.

trial plot

Two years later, in the Berlin suburban part of Lichterfeld, the inventor W. Siemens completed the construction of test railways provided with electric power, and a car equipped with a motor moved along them. The voltage was one hundred and eighty volts and was fed to one running rail - this was, as it were, a return wire.

To eliminate the possible large loss of electrical energy with poor insulation due to the use of wood sleepers as such, engineer Werner Siemens had to change the power supply circuit for the electric motor.

First experience of suspended electrification system

The World Exhibition in Paris became the platform where people saw the electric road with the use of an outboard working drive. Such power supply was in the form of an iron tube suspended above the railroad tracks. A longitudinal cut was made in the lower part of the tube. A shuttle moved in the inside of the pipe, which was connected by means of a flexible wire through the existing slot and attached directly to the locomotive surface of the roof, thus transferring current to the electric motor.

A similar tube was suspended side by side, parallel to the first tube, and served as a reverse drive. A similar system was used on the trams created in 1884, which appeared on the German and Austrian territories in the cities of Offenbach, Frankfurt, Vorderbrühl and Mödling. To ensure the tram traffic, a voltage of three hundred and fifty volts was supplied.

The Irish city of Kinresh in the same years became a kind of platform for innovators who used the third rail as a current conductor on tram lines. It was installed using insulators that were parallel to the running rails. Unfortunately, this new scheme did not have a long practical application, since in urban conditions, it was a clear hindrance to pedestrians and horse teams.

The work of a Russian engineer

The most interesting thing is that Fyodor Apollonovich Pirotsky warned about all these circumstances of technical doom for supplying power to an electric motor in one of his works, published in the newspaper edition of St. Petersburg Vedomosti. They directly stated that his offspring in the form of an electric railway is the simplest and cheapest construction. There is no need to incur additional costs for laying the middle rail line, which increases the cost of the project by five percent at once and hinders carriage traffic on city streets. The implementation of his project will not require the purchase of cast-iron poles, which cost a lot of money. Subsequently, foreign inventors heeded such a reasonable warning from a Russian engineer and put everything into practice.

Inventor F.A. Pirotsky was actively engaged in the implementation of his project, realizing that urban and railway transport had no future without electricity. Based on the results of his new research and testing, there will be a two-tier motor car that appeared on the streets of St. Petersburg, moving along the rails. In 1881, this car was exhibited at the Paris exhibition.

The English city of Brighton became a pioneer in the practical implementation of the Russian engineer's project in 1884. The length of the electric railway, where only one rail was powered, was seven miles. As a result, the net profit of one electric car, compared with a horse-drawn carriage, during the working day amounted to four hundred and twenty francs.

Developments of American engineers

On the American continent, too, they did not sit idly by, but were actively engaged in improving the method of current supply on an already created electric locomobile.

American researcher T.A. Edison conducted search work on the improvement of a railway locomotive that consumes electricity as fuel. Over a four-year period of time, until 1884, T.A. Edison managed to create three short track lines. The version of the locomotive created, running on electric current, was more like a locomotive locomotive model. Power was provided by generators. One of the track rails was powered from the negative, the other rail was connected to the positive generator pole. Already in 1883, at the Chicago exhibition, a modern locomotive for that time appeared on one of the sites, consuming electric current, named as “The Judge”. The creation of this electric locomotive version was carried out in close collaboration with another inventor, S.D. Field.

At the same time, the American engineer L. Daft managed to build the first model of the main electric locomotive, named as "Atreg". The locomotive used standard gauge on the railroad tracks from McGregor to Saratoga. Subsequently, L. Daft manages to improve the technical qualities of his own locomotive version, but now it is called “Benjamin Franklin”, its mass is ten tons, its length is four meters. There were four drive wheels. The supply of electric current, whose voltage was two hundred and fifty volts, was carried out through the third rail, which ensured the operation of the motor, whose power reached the level of one hundred and twenty-five horsepower. They were enough for the train to have eight cars, and they followed, driven by an electric locomotive at a speed equal to sixteen kilometers per hour.

Swiss cog road

The Swiss engineer Mr. R. Thorn, in the same 1884, built an experimental railway with gearing. As a result, the village of Tori and the mountain hotel received a transport artery with a steep slope, along which a small electric locomotive with four driving wheels followed. The power parameters were insignificant and allowed only four people to carry passengers. Going down the slope, the braking mode was turned on, and the electric motor became a generator, giving the generated electrical energy to the network.

Electrification in Russia

Project

Designers of all countries worked to improve the existing electric locomotive versions, as well as on the technique of supplying electricity to the locomotive.

Electrification went its own way in the Russian Empire. The project on how to electrify the first domestic railway appeared at the very end of the nineteenth century, in 1898. But to start building the Oranienbaum electrical line from St. Petersburg to Krasnye Gorki was possible only in 1913. It was not possible to implement the existing plans in full due to the outbreak of the First World War. As a result, limited sections of the road became the city tram route. In Strelna, trams still follow the tracks.

In the post-revolutionary period, the young government of the RSFSR initiated the development of the well-known GOELRO plan and approved it in 1921. The electrification of the tracks was to be completed in ten to fifteen years. The length of the new tracks under the project was three thousand five hundred kilometers, covering only a small part of the most important areas.

Beginning of work

The first railways with electric traction appeared in 1926 on the route from Surakhani to Sabunchi and further to the capital of Azerbaijan - Baku. Three years later, electric trains master the suburban route from Moscow-Passenger to Mytishchi along the Northern Railway.

A little more time passed, and in 1932 the Suramsky pass section received electricity. Now on this road the main traffic was provided by electric locomotives. Electric traction system used D.C., the voltage of which reached a value of three thousand volts. In subsequent years, it was widely used on the railways of the Soviet Union. The first days of electric locomotive operation clearly showed their advantage in comparison with locomotive traction. These indicators were productivity and energy efficiency.

By 1941, the length of all routes provided with electrical energy was one thousand eight hundred and sixty-five kilometers.

post-war period

In the first post-war year, electrified lines reached their total length of two thousand twenty-nine kilometers. It should be noted that six hundred and sixty-three kilometers of the road were restored, and in fact, practically rebuilt.

There was an active restoration of the production capacities of the destroyed factories during the war. A new enterprise appears in the city of Novocherkassk, which specializes in the production of electric locomotives. Two years after the war, the Riga enterprise for the production of electric trains began to operate.

We must not forget that in that difficult post-war period, the electrification of railways required significant infusions of monetary allocations. Therefore, the volume of growth of tracks with electricity lagged far behind the planned plans and amounted to only thirteen percent. There were many reasons for this, starting with scarce funding for the work, and ending with the high cost of materials needed to conduct such construction.

50s

In the fifties of the twentieth century, the level of earned value in relation to planned loads was seventy percent.

At the 20th Party Congress, the First Secretary of the Central Committee of the CPSU N.S. Khrushchev severely criticized the entire leadership of the Ministry of Railways. Some officials were removed from their positions.

One of the tasks of the fifth five-year plan was the construction of new power plant facilities that could meet the needs of an electrified railway.

Subsequent master plans being created required forty thousand kilometers of railway lines to be electrified by 1970.

Building up the pace

And again, industrialization helps to achieve an annual development for the construction of railways equipped with electricity in the amount of two thousand kilometers.

By March 1962, victorious reports appeared about the fulfillment of planned loads by one hundred and five percent, which in physical terms was eight thousand four hundred and seventy-three kilometers. All this clearly testified to the previous lag behind the level of desired results.

In the seventies of the twentieth century, mass replacement with semiconductor rectifiers began to replace mercury rectifiers standing at substations. Each new substation being built was equipped with only semiconductor equipment. All this meant that the most powerful and reliable inverter units appeared in the Soviet Union. They made it possible to return excess energy, which was generated by rolling stock during the period of electric braking, to the primary external network.

Safe and quick disconnection of current in a contact wire network has always been difficult and painful, especially during a short circuit.

Finally, powerful switches appeared at the railway substations.

They were installed in pairs in a sequential pattern.

Russian period

With the onset of the twenty-first century, there is a noticeable decrease in the pace of construction of electrified lines of communication in Russian Railways, a year - this is four hundred and fifty kilometers. Sometimes this value dropped to one hundred and fifty kilometers, and sometimes rose to seven hundred kilometers. A significant part of the electrified tracks was transferred to the use of alternating current. Similar modernization was carried out on the Caucasian, October roads and in the Siberian directions.

Sochi 2014

On the eve of the 2014 Winter Olympics, a new electrified railway was built immediately along the route from Adler to Krasnaya Polyana. Today, the Republic of Belarus continues to work on the electrification of railways on its territory.