The minimum allowable insulation resistance value. Cable insulation resistance

Purpose of measurements

Insulation resistance measurement cable lines, electrical wiring and electrical equipment is made in order to identify insulation defects.

1. General Provisions

1.1. Insulation resistance power cable lines up to 1000 V is measured with a megohmmeter for a voltage of 2500 V for 1 minute, while testing is carried out simultaneously increased voltage. The insulation resistance must be at least 0.5 MΩ.

1.2. The insulation resistance of AC motors with voltage up to 660 V is measured with a megohmmeter with a voltage of 1000V. The insulation resistance must be at least 1 MΩ in the cold state, and 0.5 MΩ at a temperature of 60 degrees.

1.3. Measurement of resistance of windings and insulation of bandages of machines direct current(windings relative to the body and bandages relative to the body and the windings held by them) together with the circuits and cables connected to them are made at a rated voltage up to 500 V with a 500V megohmmeter, and at a rated voltage above 500V with a 1000V megohmmeter. The insulation resistance must be at least 0.5 Mohm.

1.4. The insulation of household stationary electric stoves is measured with a 1000V megohmmeter at least once a year in the heated state of the stove. The insulation resistance must be at least 1 Mohm.

1.5. Insulation resistance of electrical equipment of cranes or elevators is carried out at least once a year. The insulation resistance must be at least 0.5 MΩ.

1.6. The insulation of power and lighting wiring is measured with a 1000V megohmmeter with the fuses removed in the area between the removed fuses or behind the last fuses between any wire and ground, as well as between two wires. When measuring in power circuits, electrical receivers must be turned off. When measuring in power circuits, electrical receivers, as well as devices, devices, etc., must be turned off. When measuring the insulation resistance in lighting circuits, the lamps must be turned out, and the sockets, switches and group shields are connected. In lighting circuits from group panels to luminaires, it is allowed not to measure the insulation resistance if a significant amount of work is required to dismantle the circuit to check the insulation and these circuits are protected by fuses. Checking the condition of such circuits, instruments and apparatus should be carried out by a thorough external examination at least once a year. When the neutral is grounded, the inspection is carried out together with the verification of ensuring the operation of the protection (by measuring the current of a single-phase short circuit).

The insulation resistance of electrical wiring in particularly damp and hot rooms, in outdoor installations, as well as in rooms with a chemically active environment, is measured in full at least once a year. The insulation resistance must be at least 0.5 MΩ.

1.7. Distribution devices, shields and conductors. The insulation resistance is measured for each section of the switchgear with a 1000V megohmmeter. It is carried out, if possible, simultaneously with the testing of electrical installations of power and lighting circuits connected to devices, panels or conductors. The insulation resistance must be at least 0.5 MΩ.

1.8. Secondary circuits for control, protection, measurement, automation and telemechanics. It is allowed not to measure the insulation resistance if the test requires a significant amount of work to dismantle the circuit and these circuits are protected by fuses or releases that have characteristics inversely dependent on current. Checking the condition of such circuits, instruments and apparatus should be carried out by a thorough external examination at least once a year. When the neutral is grounded, the inspection is carried out together with the verification of ensuring the operation of the protection (measurement of the short-circuit current).

1.9. Each connection of secondary circuits and power supply circuits of switches and disconnectors drives.

Measurement of insulation resistance is carried out with a 1000V megger with all connected devices (drive coils, controllers, relays, devices, secondary windings current and voltage transformers, etc.). The insulation resistance must be at least 1 MΩ.

1.10. The specific measurement time (according to clause 1.6, specified in clause 1.2 of the instructions for the norms) is determined by the person responsible for the electrical economy on the basis of the above standards, departmental or local PPR system in accordance with standard and factory instructions, depending on local conditions and the state of electrical installations.

2. Instruments and measuring instruments

Measurements are carried out by megohmmeter type E6-24.

3. Qualifying and quantitative composition brigades

Work on measuring insulation resistance is carried out by order of a team of at least two people, of which the work foreman must have an electrical safety group not lower than the fourth, and a member of the brigade not lower than the third. Both team members must be qualified to conduct electrical tests.

4. Measurement procedure

4.1. Measurement of insulation resistance is carried out between all phases and between each phase and zero in sections between switching devices, starting from the power board and ending with the end user.

4.2. The value of the resistance measured within 1 min is taken as the insulation resistance.

5. Sequence of testing

5.1. Connect the connecting wires to the "Rx" terminals of the megger

5.2. To measure the insulation resistance between phases A and B (Ra-b), connect one test lead to phase A of the measured section, and the other to phase B, press and hold the "Rx" button or use the "capture" mode of the "Rx" button, when the measurement result will appear on the display.

5.3. At the end of the measurement, the removal of residual voltage from the object automatically begins, the current value of which is displayed with an intermittent glow until it drops to 40 V.

5.4. To measure the insulation resistance R a - s, disconnect the connecting wire from phase B and connect it to phase C. Measure Ra - s according to clause 5.2.

5.5. Disconnect connecting wire A and connect it to phase B. Measure r in - c according to paragraph 5.2.

5.6. Disconnect the connecting wire from phase B and connect it to zero. Measure Re - 0 according to item 5.2.

5.7. Disconnect the connecting wire from phase C and connect it to phase B. Measure rb - 0 according to paragraph 5.2.

5.8. Disconnect the connecting wire from phase B and connect it to phase A. Measure Ra - 0 according to paragraph 5.2.

5.9. Disconnect the connecting wires from phase A and zero.

5.10. Carry out measurements according to paragraphs 5.2 - 5.9 on the remaining sections of the electrical installation.

6. Measures for the safe conduct of work

6.1. The measurement of the insulation resistance of electrical installations must be carried out by specially trained personnel of the electrical laboratory

6.2. The composition of the team in the production of measurements, see paragraph 3.

6.3. The foreman and members of the team must have personal certificates of the established form on checking the knowledge of safety precautions, and the assigned electrical safety group with a mark on the right to take measurements in the column of the certificate for the right to carry out special work.

6.4. The team must be instructed in electrical safety, taking into account the features of the electrical installation on which it will work. The foreman, in addition, must be instructed on the power supply scheme of the installation.

The briefing is documented by an entry in the briefing log with the signatures of the instructed persons and the person conducting the briefing.

The briefing should be carried out by a person with group 5 from the administrative and technical personnel, or with group 4 from the operational or operational and maintenance personnel of the operating organization.

6.5. Preparation of the workplace and admission to work is carried out by operational personnel.

6.6. Connecting a megohmmeter to the measured circuit and measuring the insulation resistance must be carried out with the voltage off, in compliance with all labor protection rules for the operation of electrical installations, i.e. with hanging on the wire of the switching device of the poster “Do not turn on. People work "and with checking the absence of voltage between all phases and each phase and zero. If necessary, measures must be taken to protect the non-insulated current-carrying parts of neighboring electrical installations that are energized and the opposite end of the cable under test.

7. Registration of measurement results

The measurement results are recorded in the protocol. Based on a comparison of the measurement results with the requirements of paragraphs 1.3-1.10 of this methodology, a conclusion is made about the compliance of the insulation resistance with the requirements of the PUE and PTEEP. The protocols are summarized in a report, which is approved by the head of the laboratory. A defect list is attached to the report, in which all defects found during the measurement are entered.

8. List of regulatory documents

8.1. GOST R 50571.16-2007 Electrical installations of buildings. Part 6. Tests.

8.2. Rules technical operation electrical installations of consumers (approved by order No. 5 dated 13.01.2003 of the Ministry of Energy Russian Federation, come into effect on July 1, 2003).

8.3. Rules for the installation of electrical installations. Sixth edition, revised and supplemented, with changes by Glavgosenergonadzor of Russia, Moscow, St. Petersburg 2001. Seventh edition: section 1 - chapters 1.1; 1.2; 1.7; 1.9. Moscow 2002; chapter 1.8. Moscow 2004; section 2 - chapters 2.4; 2.5. Moscow 2003; section 4 - chapters 4.1; 4.2. Moscow 2004; section 6. Moscow 2002; section 7 - chapters 7.1; 7.2 Moscow 2002; 7.5; 7.6; 7.10 Moscow 2002.

8.5. Intersectoral rules on labor protection (safety rules) during the operation of electrical installations. POT R M - 016 -2001. RD 153-34.0 - 03.150 - 00.

8.4. Instructions for the use and testing of protective equipment used in electrical installations (Moscow, 2004).

8.7. Volumes and standards for testing electrical equipment. RD 34.45-51.300-97. Moscow, 2001

8.8. State standard of the Russian Federation GOST R IEC 449-96.

8.9. Rules for the technical operation of consumer electrical installations (approved by Order No. 6 dated January 13, 2003 of the Ministry of Energy of the Russian Federation, put into effect on July 1, 2003).

9. Normalized values of measured quantities

The measured values of insulation resistance must meet the requirements given in Table 1. Volumes and standards for testing electrical equipment. RD 34.45-51.300-97. Moscow, 2001 tab. 2.6.1, in table.2. PUE table 1.8.34., in table 3. PTEEP table 37

Table 1

Test item |

Megaohmmeter voltage, V | |

|

6. Distribution devices 4), shields and conductors |

4) The insulation resistance of each section of the switchgear is measured.

|

table 2 |

||

|

Test item |

Megaohmmeter voltage, V |

The smallest allowable value of insulation resistance, MΩ |

|

one . DC busbars on control panels and in switchgears (with disconnected circuits) 2. Secondary circuits of each connection and supply circuits of switches and disconnectors drives 1) . 3. Control, protection, automation and measurement circuits, as well as excitation circuits of DC machines connected to power circuits 4. Secondary circuits and elements when powered from a separate source or through an isolating transformer, designed for an operating voltage of 60 V and below 2) 5. Wiring, including lighting networks 3) 6. Distribution devices 4), shields and current ducts (bus ducts) | ||

1) The measurement is made with all connected devices (drive coils, contactors, starters, circuit breakers, relays, devices, secondary windings of current and voltage transformers, etc.).

2) Measures must be taken to prevent damage to devices, especially microelectronic and semiconductor components.

3) Insulation resistance is measured between each wire and ground, and between every two wires.

4) The insulation resistance of each section of the switchgear is measured

The value of the test voltage for relay protection circuits, electric automation and other secondary circuits with all connected devices (drive coils, automatic machines, magnetic starters, contactors, relays, devices, etc.) is assumed to be 1000 V 1. Lighting networks are tested with the specified voltage in cases where the wiring has a reduced insulation level compared to the norm. In other cases, the test can be carried out with a megohmmeter for a voltage of 2500 V.

The duration of application of the test voltage is 1 min.

Secondary circuits designed for an operating voltage of 60 V and below, as well as circuits containing devices with microelectronic elements, with a voltage of 1000 V at a frequency of 50 Hz are not tested.

During current repairs (T), it is allowed to test with a rectified voltage of 2500 V using a megohmmeter or a special installation.

|

Table 3 Minimum allowable values of insulation resistance of elements electrical networks voltage up to 1000 V (PTEEP tab. 37) |

|||

|

Element name |

Megaohmmeter voltage, V |

Insulation resistance, MOhm |

Note |

|

Electrical products and devices for rated voltage, V: over 50 to 100 over 100 to 380 |

Must comply with the manufacturer's instructions, but not less than 0.5 |

During measurements, semiconductor devices in products must be shunted |

|

|

Distribution devices, shields and conductors |

At least 1 |

Measurements are made on each section of the switchgear |

|

|

Wiring, including lighting networks |

Not less than 0.5 |

Insulation resistance measurements in especially hazardous premises and outdoor installations are carried out once a year. In other cases, measurements are made once every 3 years. When measuring in power circuits, measures must be taken to prevent damage to devices, especially microelectronic and semiconductor devices. In lighting networks, lamps must be unscrewed, sockets and switches connected |

|

|

Secondary circuits of switchgears, circuits for supplying drives of switches and disconnectors, circuits for control, protection, automation, telemechanics, etc. |

At least 1 |

Measurements are made with all connected devices (coils, contactors, starters, switches, relays, devices, secondary windings of voltage and current transformers) |

|

|

Cranes and elevators |

Not less than 0.5 |

Produced at least once a year |

|

|

Stationary electric stoves |

At least 1 |

Produced when the plate is heated at least 1 time per year |

|

10. Test frequency

1.2. The frequency and standards of measurements are regulated by the standards for testing electrical equipment and apparatus for electrical installations of consumers (Appendix 3 PTEEP). Measurement of insulation resistance is carried out before commissioning, after the reorganization and overhaul of the electrical installation. Measurement of insulation resistance in existing electrical installations is carried out in accordance with the approved PPR schedules, but at least once a year:

For secondary circuits of relay protection and automation;

For electrical wiring in particularly damp, hot rooms, outdoor installations, as well as their switchboards;

For household stationary electric stoves.

For hand power tools, portable lamps with auxiliary equipment - at least 1 time in 6 months

Electrical installations, devices, secondary circuits, the test standards for which are not definedin sections 2-27 (PTEEP), and electrical wiring with voltage up to 1,000 V

K, T, M - are produced within the time limits established by the PPR system.

|

Name of the test |

Type of test |

Test norms |

Directions |

|

1.Insulation resistance measurement 2. High voltage test of industrial frequency of electrical products with a voltage higher than 12V AC and 120V DC, including: 1) insulation of the windings and current-carrying cable of a portable power tool relative to the body and external metal parts |

See table. 37 (app. 3.1) Duration of voltage application (Uisp) - 1 min For power tools for voltages up to 50 V, Uisp is assumed to be 550 V. For power tools for voltages above 50 V and power up to 1 kW - 900 V, with power over 1 kW - 1350 V |

Power tools with a housing made of insulating material must have wrapped in metal foil and connected to the ground electrode the body and the parts connected to it. |

|

With an insulation resistance of more than 10 MΩ, the overvoltage test can be replaced by a one-minute measurement of the insulation resistance with a megohmmeter for voltage |

|||

|

2) winding insulation step-down transformers 3. High voltage test of industrial frequency of power and secondary circuits with operating voltage above 50V AC, not containing devices with microelectronic elements: 1) insulation of switchgear elements of circuit breaker drives, short circuits, separators, devices, as well as secondary circuits for control, protection, automation, telemechanics, etc. 2) isolation of power and lighting electrical posting |

The test voltage should be 1350 V at the rated voltage of the primary winding of the transformer 127-220V, and 1800 V - at the rated voltage of the primary winding 380-440 V Test duration - 1 minute. Test voltage - 1000 V |

The test voltage is applied alternately to each of the windings. In this case, the remaining windings must be connected to grounded case and magnetic circuit When testing with a megohmmeter for 2,500 V, it is possible not to measure with a megohmmeter for Produced if the insulation resistance is below 1 MΩ |

Services are provided by the Official Dealer, ENETRA Technologies. Among the numerous range of electrical equipment offered by our company, the latest development of METZ - transformers with aluminum foil winding TMG21. The novelty is produced with a capacity of 630 and 1000 kVA and will replace similar transformers of series 11, TMG 11.

Any electrical product is characterized by a number of parameters. For cables, one of the main ones is the insulation resistance. There are certain standards that must be taken into account during the design and installation, as well as during the operation and maintenance of communication routes.

What are the cable insulation resistance standards? The fact is that there are often discrepancies on this issue. This is due, according to the author, to several factors.

First, the cable is a generalized concept. This group of products includes samples used in the laying of power, signal and telephone lines. Cables can be coaxial (radio frequency), control, distribution and general purpose. That is, there are many options for the design of protective shells, which differ, among other things, in thickness.

Secondly, a variety of materials are used to make insulation - rubber, plastics, even paper impregnated in a special way. Although in more modern cables, protection is usually complex, that is, combining various dielectric layers.

Thirdly, what kind of insulation resistance are we talking about - the outer shell or the surface coating of the cores?

Fourthly, the specifics of the installation and further operation of a particular cable should be taken into account. For example, the route laying method is open or closed. Where it fits - in the ground, in trays (there are enough options). What characterizes the environment - the limiting value and changes in temperature, humidity, aggressiveness, and so on.

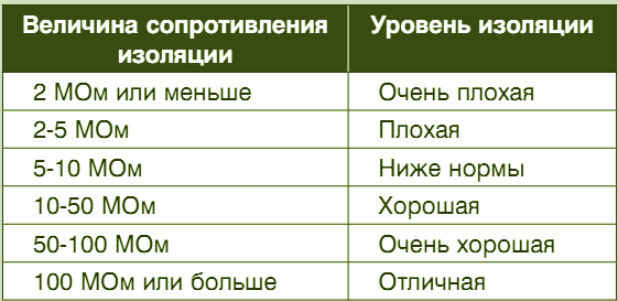

Insulation resistance - standards for cables

All values are in MΩ.

Power cables

- High voltage (more than 1,000 V). There are no rules for them. That is, the higher the insulation resistance, the better. It is generally accepted that its value should not be less than 10.

- Low voltage (up to 1,000 V). In fact, we are talking about electrical wiring and secondary circuits of various installations. The minimum limit of the insulation resistance value is 0.5. More detailed information on this issue can be found in the PUE of the 7th edition (Table 1.8.34 and clause 1.8.37).

Control, signal, general purpose cables

This is a fairly large group of products. It includes cables mounted for control circuits, automation, power supply for electric drives, connection of protective, switchgear, and so on. For them, it is considered the norm if the insulation resistance is not lower than 1. But this is a generally accepted indicator. The exact value, depending on , should be sought in its accompanying documentation.

For communication cables, the resistance standards are somewhat different, more “rigid”. For city lines n / h - at least 5, trunk lines - 10 (MOhm / km).

If the cable has an outer sheath of aluminum with a PVC coating, then the resistance rate is higher and equals 20.

Note. PUE stipulates that the measurement of insulation resistance is carried out with a megohmmeter with the voltage of the inductor:

- for cables in circuits not exceeding 500 V - 500;

- up to 1,000 V - 1,000;

- all others - 2,500.

Specialists do not need to explain that all requirements for insulation resistance are specified in terms of reference, GOST and SNiP for a certain type of work. Its value is easy to find out from the cable passport, and if it is necessary to control the condition of the product, make an appropriate measurement. The specifics of this operation are specified in clause 1.8.7. PUE (7th edition).

In everyday life, to assess the degree of wear of the insulation of the power cable, you can use the following table, which reflects the approximate average standards.

Since a non-professional is not able to take into account all the nuances of the design of the product and its use, this, as a rule, is quite enough to understand whether this sample is worth laying or it is already unusable. That is, discard. Well, if there is any doubt, then it is useful to consult with a specialist.

1. Purpose of the measurement .

Measurements are carried out in order to verify that the insulation resistance complies with established standards.

2. Security measures.

2.1 Technical measures.

Before and during measurements, it is necessary to carry out technical measures in accordance with the “Safety Rules” (PTB). When working with a megohmmeter, it is necessary to be guided by paragraphs B 3.7.17-B 3.7.22 PTB.

2.2 Organizational events.

Measurements with a megohmmeter are allowed to be performed in installations with a voltage above 1000V by two persons, one of whom must have an electrical safety group of at least IV. The work is done in sequence. In installations with voltage up to 1000V, measurements are performed by two persons, one of whom must have a group of at least III. The work is carried out in the order of current operation with subsequent recording in the operational log.

3. Normalized values .

The frequency of tests and the minimum allowable value of insulation resistance must comply with those specified in the test standards for electrical equipment and apparatus of the “Rules for the technical operation of consumer electrical installations”. As a rule, the insulation resistance of BSSN and FSSN systems measured with a 250 V megger must be at least 0.25 MΩ, power circuits up to 500 V (except for BSSN and FSSN systems) measured with a 500 V megohmmeter must be at least 0.5 MΩ, and secondary circuits - not less than 1 MΩ. The insulation resistance of power circuits above 500 V, measured with a megohmmeter at 1000 V, must be at least 1.0 MΩ, (GOST R50571.16-99). The insulation resistance of electrical wiring, including lighting networks, measured with a megohmmeter at 1000 V must be at least 0.5 MΩ, (PTEEP clause 28.1)

4.

Applied devices.

To measure insulation resistance, megohmmeters of types are used: MI 3102H (for voltage 100 V, 250 V, 500 V 1000 V and 2500 V) and, E6-24 (for voltage 500 V 1000 V and 2500 V). These devices have their own power source - a DC generator and allow direct reading of readings in megaohms and gigaohms.

5. Measurement of insulation resistance of electrical equipment.

5.1. Insulation resistance measurement power cables and wiring

When measuring insulation resistance, the following must be taken into account:

Measurement of the insulation resistance of cables (with the exception of armored cables) with a cross section of up to 16 mm2 is carried out with a megohmmeter for 1000 V, and above 16 mm2 and armored - with a megometer for 2500 V; measurement of the insulation resistance of wires of all sections is carried out with a 1000 V megameter.

In this case, it is necessary to make the following measurements:

On 2- and 3-wire lines - three measurements: L-N, N-PE, L-PE;

On 4-wire lines - 4 measurements: L1-L2L3PEN, L2 - L3L1PEN, L3-L1L2PEN, PEN-L1L2L3, or 6 measurements: L1-L2, L2-L3 ,

L1-L3, L1-PEN, L2-PEN, LЗ-PEN- on 5-wire lines - 5 measurements: L1-L2L3 NPE, L2-L1L3NPE, LЗ-L1L2PE, N-L1L2L3PE, PE-NL1L2L3, or

10 measurements: L1-L2, L2-L3, L1-L3, L1-N, L2-N, L3-N, L1-PE, L2-PE, LZ-PE, N-PE.

It is allowed not to measure the insulation resistance in lighting networks that are in operation, if this requires significant work to dismantle the circuit, in this case, at least once a year, it is required to perform visual inspection together with checking the reliability of operation of overcurrent protective equipment (determination of currents single-phase short circuits in accordance with paragraph 1.7.79 of the PUE).

If the electrical wiring in operation has an insulation resistance of less than 0.5 MΩ, then the conclusion about their suitability is made after testing them with alternating current of industrial frequency with a voltage of 1 kV in accordance with the recommendations given in this publication.

5.2. Measurement of insulation resistance of power electrical equipment

The value of the insulation resistance of electrical machines and apparatuses depends to a large extent on temperature. Measurements should be made at an insulation temperature of at least +5°C, unless otherwise specified in special instructions. At lower temperatures, the measurement results, due to the unstable state of moisture, do not reflect the true performance of the insulation. If there are significant differences between the measurement results at the installation site and the manufacturer's data due to the temperature difference at which the measurements were taken, these results should be corrected according to the manufacturer's instructions.

The moisture content of the insulation is characterized by an absorption coefficient equal to the ratio of the measured insulation resistance 60 seconds after applying the megger voltage (R60) to the measured insulation resistance 15 seconds later (R15),

Cubs = R60/ R15

When measuring the insulation resistance of power transformers, meggers with an output voltage of 2500 V are used.

Measurements are taken between each winding and the frame and between the windings of the transformer.

In this case, R60 must be brought to the results of factory tests, depending on the temperature difference at which the tests were carried out.

The value of the absorption coefficient should differ (in the direction of decrease) from the factory data by no more than 20%, and its value should not be lower than 1.3 at a temperature of 10-30°C. If these conditions are not met, the transformer must be dried.

Minimum allowable resistance insulation for installations in operation are given in Appendix 3 of PTEEP, table 9, and for installations put into operation - in Ch. 1.8. PUE, table 8. The insulation resistance of hand-held electrical machines is measured relative to the housing and external metal parts with the switch on.

The body of the power tool and the parts connected to it, made of dielectric material, must be wrapped in metal foil connected to the ground loop for the duration of the test.

If the insulation resistance in this case is at least 10 MΩ, then the insulation test with increased voltage can be replaced by measuring its resistance with a megohmmeter with an output voltage of 2500 V for 1 minute.

For portable transformers, the insulation resistance is measured between all windings, as well as between the windings and the housing. When measuring the insulation resistance of the primary winding, the secondary must be closed and connected to the case.

Insulation resistance of circuit breakers and RCDs are produced:

1. Between each pole terminal and opposite pole terminals connected to each other when the circuit breaker or RCD is open.

2. Between each opposite pole and the remaining poles connected to each other when the switch or RCD is closed.

3. Between all interconnected poles and the body wrapped with metal foil.

At the same time, for circuit breakers for household and similar purposes (GOST R50345-99) and RCDs when measured according to p.p. 1, 2 insulation resistance must be at least 2 MΩ, according to paragraph 3 - at least 5 MΩ.

For other circuit breakers (GOST R50030.2-99), in all cases, the insulation resistance must be at least 0.5 MΩ.

6. Measurement of insulation resistance with the E6-24 device

6.1.

The appearance of the device is shown in Figure 1

Picture 1

1, 2, 3 - sockets for connecting cables

4 - indicator

5 - indicator of units of measurement (from top to bottom, respectively:

Voltage, V

Gom resistance

Mohm resistance

6 - test voltage indicator (from left to right, respectively: 500V, 1000V, 2500V)

7 - battery charge indicator

8 - switch on and off device status

9 - test voltage setting button

10 - button for displaying results from memory

11 - resistance measurement button

6.2.

Before starting measurements, make sure that there is no voltage on the object under test, carefully clean the insulation near the measuring point from dust and dirt and for 2-3 minutes. Ground the object to remove possible residual charges from it. After the end of the measurements, the object under test must be discharged by short-term grounding.

To connect the megaohmmeter to the device or line under test, separate wires with a high insulation resistance (usually not less than 100 MΩ) should be used.

Before use, the megohmmeter should be subjected to a control check, which consists in checking the reading on the scale with open and short-circuited wires. In the first case, the arrow should be at the “infinity” scale mark, in the second - at zero.

In order to prevent leakage currents on the insulation surface from affecting the readings of the megohmmeter, especially when measuring in wet weather, the megohmmeter is connected to the object being measured using the clamp E (screen) of the megohmmeter. With this connection, leakage currents on the insulation surface are diverted to the ground, bypassing the winding of the device.

The insulation resistance value is highly temperature dependent. Insulation resistance should be measured at an insulation temperature of at least +5°C, unless otherwise specified in special instructions. At lower temperatures, the measurement results, due to the unstable state of moisture, do not reflect the true performance of the insulation.

When measuring the insulation resistance to ground using a megohmmeter, it is recommended to connect the “+” terminal to the current-carrying part of the installation under test, and the “-” (ground) terminal to its body. When measuring insulation resistance electrical circuits, not

connected to ground, the connection of the megohmmeter clamps can be any.

The use of the “E” clamp (screen) significantly increases the measurement accuracy at high insulation resistances, eliminates the influence of surface leakage currents and thus does not distort the measurement results.

To connect the megaohmmeter to the object under test, it is necessary to have flexible wires with insulated handles and restrictive rings at the ends. The length of the wires should be as short as possible.

Before starting the measurement, it is necessary to measure the insulation resistance of the connecting wires. The value of this resistance must be at least the upper limit of the megohmmeter.

The insulation resistance is taken as the 60-second resistance value R-60, fixed on the megohmmeter indicator after 60 s, which is counted automatically.

Before starting measurements, you must make sure: that there is no voltage on the object under test, that the equipment under test, wires, cable funnels, etc. are clean, and that all parts with reduced insulation or reduced test voltage are disconnected and shorted. If available on site AC voltage the megaohmmeter will detect it automatically. In the absence of voltage, you can begin to take measurements.

6.3. Switching the value of the test voltage of 500 V, 1000 V and 2500 V is done by briefly pressing the "UR" button.

6.4. To take a measurement, press and hold the "RX" button. When the button is released, the measurement process will stop. Double pressing the "RX" button leads to its capture, and the measurement process will occur for a specified time interval without holding it (from 1 to 10 minutes), which can be set using the UR and MRx / K buttons after turning on the megohmmeter while pressing the "RX" button . If it is necessary to terminate the measurement process early, press the “RX” button again.

6.5. Lighting up on the indicator of the symbol "P" (overflow) indicates that the resistance of the object of measurement exceeds the limit of the instrument reading of 99.9 Gom. Also, the “P” indication may appear during transients, therefore, in this case, the measurement should be continued for another 10 seconds.

6.6. Unplugging the cables from the object should be carried out no earlier than 10 seconds after the end of the test voltage supply.

7.1. Procedure for measuring insulation resistance

Step 1 Use the rotary switch to select the function Insulation.

Use the and buttons to select between the "R ISO" and "DIAGNOSTICS" functions. Select the option " R ISO". Connect the measuring cable to the EurotestXE 2.5 kV instrument.

Step 2 set the values of the following parameters and measurement limits:

Rated measuring voltage,

Minimum limit permissible value resistance.

Step 3 P Connect the test cable to the object under test. To carry out an insulation resistance measurement, follow the connection diagram shown in figure 2. If necessary, refer to the help menu. For insulation resistance measurements at voltage UN= 2.5 kV, special test leads must be used, since the test signal is applied to different measuring terminals than for measurements at UN ≤ 1 kV! The standard 3-wire measuring cable, cable with euro plug and "commander" probes can only be used for resistance measurements at UN≤ 1 kV!

Figure.2 : Connecting the 3-wire measuring cable and test probe with

ferrule (UN ≤1 kV)

For insulation resistance measurements at voltage UN= 2.5 kV, a two-wire 2.5 kV measuring cable must be used. Connection in accordance with the connection diagram shown in Figure 3

Figure 3 : Connecting two-wire 2.5 kV measurement cable (UN =2.5 kV)

Step 4 P Before starting measurements, check the displayed warnings and the operating voltage / output monitor. If the measurement is enabled, press and hold the TEST button until the result stabilizes. During measurements, the display shows the actual resistance value. After the TEST button is released, the last measured value is displayed, accompanied by a pass/fail rating (if applicable).

Displayed results:

R… … … … Insulation resistance,

um… … … Measuring voltage.

Save the measurement results for future documentation.

7.2. Classification of insulation resistance measurement results while saving

When saving, after pressing the button Memory, ten insulation resistance subfunctions are available:

The procedure for measuring the insulation resistance is the same regardless of which sub-function is selected. However, it is important to select the appropriate sub-function in order to correctly classify the measurement results in the future for their correct entry in the measurement protocols.

8. Registration of measurement results .

The results of measuring the insulation resistance of wires, cables, windings of machines and devices are recorded in a protocol, the final part of which characterizes the quality of the insulation. The completed protocol is attached to the report on the commissioning of electrical equipment.

DEVELOPED:

Head of electrical laboratory

Each electrical equipment, including conductors, has its own specific parameters. Sometimes, to make the installation of electrical wiring, it is necessary to clarify each characteristic. It is imperative to know the value of the cable insulation resistance norm, since without this parameter it makes no sense to carry out installation work.

The conductor device is made in this way: two metal conductors are designed to transmit current, but they cannot exist on their own, as they are afraid of factors affecting the external environment, and they themselves are an unfavorable phenomenon. First of all, metal conductors will interfere with each other until an emergency situation is created. Therefore, insulating materials are needed. To prevent accidents, fires or electric shocks, materials that do not conduct current are used in the production of conductive cables.

To make such isolation and, accordingly, protect a person from negative situations, rubber, plastic and other consistencies are taken as a basis. Sometimes they are mixed, creating an insulating combination with added strength. To date, there are all kinds of cables with effective insulation on the industry market, using which in installation, it is important to calculate the resistance.

Insulation resistance: standards table and calculation principle

Table of wire insulation resistance standards

We ask you to pay attention to the tabular data, here the norm of the indicator for each individual class of voltage of the electrical network is indicated.

So, let's start considering some rules regarding resistance measurements. Unfortunately, it is impossible to directly check the required dielectric value. For the further procedure, we need a megaohmmeter.

- The first thing we will do is make sure that the wiring under test is not connected to voltage;

- then all current-carrying conductors should be grounded for literally a few minutes. This is done in order to remove the remaining charge;

- the insulating layer must be dry and clean, therefore, we eliminate all impurities of dust and dirt, if any.

In the future, we work with the device. To do this, select the measurement chapel. For example, for home electrical networks, it is enough to supply 1000 volts. At the same time, you need to check the device. This method is performed strictly with closed and open conductors. In the open state, the arrow shows zero, and when closed, it should go to "infinity".

The norm of the PUE of the cable insulation resistance must confirm the value on the ohmmeter dial.

Important! It is necessary to take readings from the device after measurements only when its arrow is at rest.

Remember that resistance cable insulation should be checked at the time of the 15th and 60th second from the beginning of the rotation of the ohmmeter knob.

It is not uncommon to find insulated wires with grounding, in this situation three measurements are performed:

- between zero and phase;

- between ground and phase;

- between ground and zero.

Important! When working with the megger, wear overalls and non-conductive gloves.

To find out what insulation resistance the cable should have, you need to refer to the PUE standards for each individual section.

Insulation coating control measurements

Checking the insulation resistance of wires in the electrical panel

Cable insulation resistance is a very important indicator that indicates the performance of the conductor. To avoid unexpected breakdowns and not be in danger of electric shock, it is recommended to carry out regular inspection. What does it mean, we will tell below.

We draw your attention to the fact that the verification of electrical networks and installations with current consumption must be carried out without fail, this is stated by state regulations and a number of regulatory documents.

Therefore, you need to control:

- resistance of numerous mobile installations strictly once every six months;

- resistance of wires and electric cables in production, as well as external electrical installations no later than every year;

- the resistance of the remaining elements with the consumption of electric current is sufficient once every two and a half years.

Important! It is customary to record all measurement results in a state act, and in case of a discrepancy, be sure to indicate it.

In conclusion, we want to note that only timely monitoring and taking into account all the regulations increases the chances for the duration of the work of conductors.

With metal conductive cores is made in order to determine its performance. The quality of the signal transmitted through the conductors also depends on this indicator. Reduced insulation resistance typically results in noise on the line, which in turn leads to audible noise (telephone line), reduced bandwidth (digital data systems), or a complete loss of communication.

According to GOST 15125-92, the measurement of the insulation resistance of the communication cable should be carried out once every 6 months.

Communication cable insulation resistance standards

The electrical standards of communication cables determine the minimum values of the resistance of external insulation and core insulation, at which cable products are allowed to be used. The resistance value depends on the type and purpose of the cable.

Requirements for insulation resistance values of cables put into operation are given in GOST 15125-92, OST 45.01-98, OST 45.83-96 and other regulatory and technical documentation. Let's look at a few examples.

Insulation resistance standards for communication cables most commonly used for the construction of primary networks, public transport networks and other lines (values per 1 km of cable length, without terminals / with terminals):

Cables with tubular-paper and porous-paper insulation (, etc.) - 8000/1000 MΩ.

. Polyethylene insulation (brands -, and others) - 6500/1000 MΩ.

. Cordless-paper insulation (, etc.) - 10000/3000 MΩ.

Communication cable test

Communication cable insulation resistance measurements are also made in accordance with regulatory requirements. When performing this task, it is important to take into account the current temperature and humidity. All electrical parameters of communication cables are given by manufacturers subject to testing at a temperature of +20 °C and a cable product length of 1 km. The deviation of these parameters from the norm leads to an increase or decrease in readings. However, there are simple formulas that allow you to recalculate the resistance depending on temperature and length.

Equipment

Measurement of the insulation resistance of a communication cable is carried out with a special device called a megohmmeter. To determine the desired electrical value, these devices generate a certain voltage (from 100 V or more).

At the moment, two types of megohmmeters are used - digital and analog. In the first case, electromechanical (manual) generators and pointer indicators are used to generate voltage. Digital megaohmmeters usually use galvanic cells or batteries to generate voltage. The measurement results are displayed on a digital display. Also, some megger models do not have their own current generator and require an external power supply.

To test cable lines, reflectometers are also widely used, capable of determining various cable defects by the location (reflectometric) method. The principle of operation of the devices is as follows:

Short-wave electrical impulses are applied to the cores of the cable under test.

. If there are any defects in the cable, the applied pulse is reflected from the obstacle and returns back to the device.

. The returned signal is captured by the reflectometer sensors, measured, analyzed, after which the measurement result is displayed on the display.

Thus, with the help of reflectometers, it is possible to detect breaks, short circuits, entangled pairs, dense ground and other defects that occur, including when the cable insulation is damaged.

Requirements and test methods for communication cables

Measuring the parameters of communication cables (insulation) is a simple process, but it requires compliance with the requirements established by regulatory documentation (in particular, GOST 3345-76, GOST 2990-78). In short:

Before carrying out work, the cable must be de-energized and disconnected from all terminal devices and conductors (if it is, for example, a GTS cable, the tested cores are disconnected from the terminals of the switchboards).

. It is impossible to test with a megohmmeter over cables located in close proximity to other electrical systems, since the voltage generated by the device can create powerful electromagnetic fields that can disrupt the operation of these systems.

. It is impossible to test overhead communication lines during a thunderstorm.

. The tested conductors (cores) must be grounded.

. It is possible to disconnect the conductor under test from the "ground" only after it is connected to the corresponding terminals of the megohmmeter (i.e., the device is connected first, and only then the wires are disconnected from the "ground").

. Before and after measurements, the conductor must be freed from residual current by means of a short circuit. This operation is also performed on the measuring probes of the megohmmeter.

. To obtain an accurate result, the current is passed through the tested conductor for (and no more than!) 1 minute. After testing, the device and the tested conductor are allowed to “cool down” for 2 or more minutes, unless other figures are given in the corresponding documentation for the megohmmeter and / or cable.

. All other safety requirements are given in GOST 2990-78.

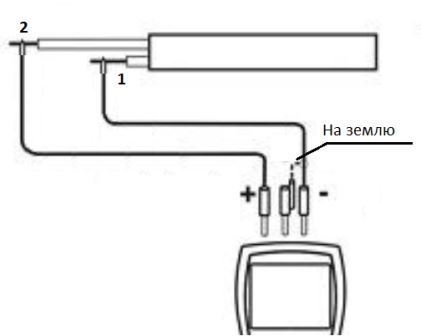

Now let's consider the process of measuring the insulation resistance of a communication cable using the example of a coaxial pair without a protective screen (we will measure the insulation resistance of the cores). According to GOST 2990-78, the conditional scheme for applying voltage to the cable cores is as follows:

Core "1" is connected to the input "R-" (the input can also be designated as "-", "Earth" or "Z") of the megohmmeter.

. Core “1” and the input “R-” of the megohmmeter are grounded.

. Core "2" is connected to the voltage source input "R +" ("+", "Rx", "Line" or "L") of the megohmmeter.

Conditional working scheme:

Measurement process:

First, the output voltage level is set on the megaohmmeter, which depends on the brand of the cable being tested (usually, to test communication cables, it is enough to apply a voltage of 500 V).

. After applying voltage to the circuit, the megohmmeter will take about 1 minute to take measurements. If this is a pointer device, it is necessary to wait for it to stop completely, for this the megohmmeter must be stationary. In the case of digital devices, this is not necessary.

. If necessary, measurements are carried out several times. As mentioned above, before each procedure, the device is allowed to “cool down” for about 2 minutes (plus or minus - depends on the characteristics of the megohmmeter).

Temperature has a strong effect on readings. environment(the higher it is, the lower the resistance and vice versa). If its value is different from +20 degrees, you must use the following "corrective" formula:

R_(20)=K*R_1, where:

R_(20) - cable insulation resistance (in our case, core insulation resistance) at +20 ° С (indicated in the passport for the cable brand);

R_1 is the resistance obtained as a result of measurements at a temperature other than +20 °C;

K is a "correcting" coefficient that allows you to determine the value of the insulation resistance that would take place at +20 ° C (the coefficients are given in the appendix to GOST 3345-76).

For example, consider a PE-insulated cable that has an initial resistance (without terminations) of 5000 MΩ. After measuring the resistance of the cores at a temperature of 15 ° C, we got a result of, say, 11,500 MΩ. According to GOST 3345-76, the correction factor "K" in the case of polyethylene core insulation is 0.48. Substituting this value into the formula, we have:

R_(20)=0.48*12500=5520 (resistance under normal conditions)

Using the following formula, you can determine the insulation resistance depending on the length of the cable:

R=R_(20)*l, where:

R_(20) - insulation resistance at +20 °С;

l is the length of the tested cable;

Take the same brand of cable 1.5 km long. We know the initial insulation resistance of the conductors under normal conditions - 5000 MΩ. From here:

R=6500* 1.5=7500 MΩ

The Cable.RF company is one of the leaders in the sale of cable products and has warehouses located in almost all regions of the Russian Federation. After consulting with the company's specialists, you can purchase the brand you need at competitive prices.