What is direct and alternating current definition. Alternating and direct current in engineering

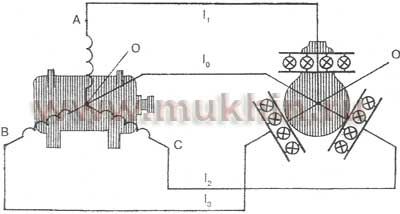

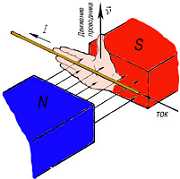

As we already know, electric current can be constant and variable. But only alternating current is widely used. This is due to the fact that the voltage and strength of the alternating current can be converted with little or no loss of energy. Alternating current obtained using alternating current generators using the phenomena of electromagnetic induction. On fig. 8 shows a primitive installation for generating alternating current.

Rice. eight.

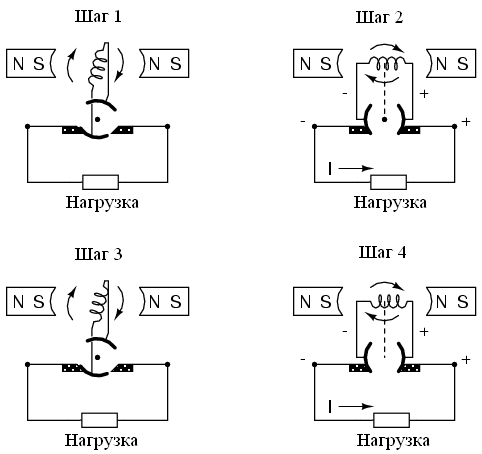

The principle of operation of the installation is simple. The wire frame rotates in a uniform magnetic field at a constant speed. With its ends, the frame is fixed on rings that rotate with it. Springs are tightly attached to the rings, acting as contacts. A changing magnetic flux will continuously flow through the surface of the frame, but the flux created by the electromagnet will remain constant. In this regard, an EMF of induction will appear in the frame. In order to determine whether the magnetic flux passing through the surface of the frame changes, you just need to compare the position of the frame in certain periods of time. To do this, take a close look at Fig. 9.

Rice. 9.

The starting point will be the position of the frame shown in Fig. 9, a. At this moment, the plane of the frame is perpendicular to the magnetic lines, and the magnetic flux will have a maximum value. Parallel to the magnetic lines, the frame will rise in a quarter of the period. In this case, the magnetic flux will become equal to zero, because not a single magnetic line passes through the surface of the frame. To determine the EMF of induction, you need to know not the magnitude of the flux, but the rate of its change. At the reference point, the induction EMF is zero, and at the third (Fig. 9, c) - the maximum value. Based on the provisions of the frame, it can be seen that the induction emf changes both the value and the sign. Thus, it is a variable (see graph in Fig. 9).

If the frame has only active resistance, then the current that occurs in the circuit under the action of the induction EMF will change over time, like the EMF itself. Such a current is called an alternating sinusoidal current. The period of an alternating current is the length of time during which the current performs one complete oscillation (this unit is denoted by the letter T). The number of complete oscillations in 1 s is called the frequency of the current and is denoted by the letter f. Frequency is measured in hertz (Hz). In industry and everyday life in most countries, alternating current with a frequency of 50 Hz is used.

Effective values of current and voltage

As you know, the variable EMF of induction causes an alternating current in the circuit. At the highest value of the EMF, the current strength will have a maximum value and vice versa. This phenomenon is called phase matching. Although current values can vary from zero to a certain maximum value, there are instruments with which you can measure the strength of alternating current.

The AC characteristic can be actions that are independent of the direction of the current and can be the same as with DC. Such actions include thermal. For example, an alternating current flows through a conductor with a given resistance. After a certain period of time, a certain amount of heat will be released in this conductor. It is possible to choose such a value of the direct current strength so that on the same conductor for the same time the same amount of heat is released by this current as with alternating current. This value of direct current is called the effective value of the alternating current.

Ammeters and voltmeters of the magnetoelectric system do not allow measurements in AC circuits. This is because with each change in the current in the coil, the direction of the torque changes, which acts on the arrow of the device. Due to the fact that the coil and arrow have a large inertia, the device does not respond to alternating current. For these purposes, devices are used that do not depend on the direction of the current. For example, these can be devices based on the thermal effect of current. In such devices, the arrow turns due to the lengthening of the thread heated by the current.

You can also use devices with an electromagnetic system of action. The movable part in these devices is an iron disk of small diameter. It remagnetizes and is drawn into the coil through which an alternating current is passed. Such devices measure the effective values of current and voltage.

Inductor and capacitor in AC purpose

The features of alternating current are the change in the strength and direction of the current. These phenomena distinguish it from direct current. For example, AC power cannot charge a battery. Also, it cannot be used for other technical purposes.

The strength of the alternating current is in direct proportion not only to the voltage and resistance, but also to the inductance of the conductors connected to the circuit. As a rule, inductance significantly reduces the strength of the alternating current. Due to the fact that the resistance of the circuit is equal to the ratio of voltage to current strength, connecting an inductor to the circuit will increase the total resistance. This will happen due to the presence of self-induction EMF, which does not allow the current to increase. If the voltage changes, then the current strength simply does not have time to reach the maximum values that it would have acquired if there were no self-induction. It follows from this that highest value AC power is limited by inductance, i.e. the greater the inductance and voltage frequency, the lower the current value.

If a capacitor bank is included in the DC circuit, then there will be no current in the circuit, because the capacitor plates are separated from each other by insulating gaskets. If there is a capacitor in the circuit D.C. cannot exist.

If exactly the same battery is connected to an alternating current circuit, then a current will appear in it. This is explained as follows. Under the influence of a changing voltage, the capacitors are charged and discharged. That is, if one plate of the capacitor had a negative charge during any half-cycle, then in the next half-cycle it will acquire a positive charge. Therefore, recharging the capacitor moves charges around the circuit. And this is the electric current, which can be detected with an ammeter. The greater the charge being moved, the greater the current strength, that is, the greater the capacitance of the capacitor and the more often it is recharged, the greater the frequency.

Three-phase AC

At present, three-phase alternating current is widely used in world industrial practice, which has many advantages over single-phase current. A three-phase system is called such a system that has three electrical circuits with their own variable EMFs with the same amplitudes and frequencies, but shifted in phase relative to each other by 120 ° or 1/3 of the period. Each such circuit is called a phase.

Rice. ten.

To obtain a three-phase system, you need to take three identical single-phase alternating current generators, connect their rotors to each other so that they do not change their position during rotation. The stator windings of these generators must be rotated relative to each other by 120 ° in the direction of rotation of the rotor. An example of such a system is shown in Fig. ten.

According to the above conditions, it turns out that the EMF that occurs in the second generator will not have time to change, compared to the EMF of the first generator, i.e., it will be 120 ° late. The EMF of the third generator will also be late with respect to the second one by 120°.

However, this method of obtaining an alternating three-phase current is very cumbersome and economically unprofitable. To simplify the task, you need to combine all the stator windings of the generators in one housing. Such a generator is called a three-phase current generator. When the rotor begins to rotate, a changing induction emf occurs in each winding. Due to the fact that the windings are shifted in space, the phases of the oscillations in them also shift relative to each other by 120 °.

In order to connect a three-phase alternator to a circuit, you need to have 6 wires. To reduce the number of wires, the winding of the generator and receivers must be interconnected, forming a three-phase system. There are two connections: star and delta. When using both methods, you can save wiring.

Star connection

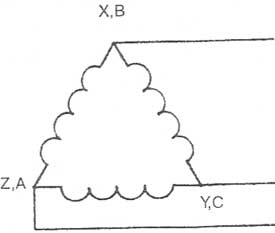

Typically, a three-phase current generator is depicted as 3 stator windings, which are located at an angle of 120 ° to each other. It is customary to designate the beginnings of the windings with the letters A, B, C, and the ends - X, Y, Z. In the case when the ends of the stator windings are connected to one common point (zero point of the generator), the connection method is called a "star". In this case, wires called linear wires are connected to the beginnings of the windings (Fig. 11 on the left).

Rice. eleven.

Receivers can be connected in the same way (Fig. 11 on the right). In this case, the wire that connects the zero point of the generator and receivers is called zero. This three-phase current system has two different voltages: between the linear and neutral wires or, which is the same, between the beginning and end of any stator winding. This value is called phase voltage (Ul). Since the circuit is three-phase, the linear voltage will be v3 times the phase voltage, i.e.:

Ul = v3Uf

Delta connection

Rice. 12.

When using this connection method, the end X of the first winding of the generator is connected to the beginning B of its second winding, the end Y of the second winding is connected to the beginning C of the third winding, the end Z of the third winding is connected to the beginning A of the first winding. An example connection is shown in fig. 12. With this method of connecting phase windings and connecting a three-phase generator to a three-wire line, the linear voltage is compared in its value with the phase one:

Nowadays, electric current is used in all sectors of the national economy. And we know that there are two types of current: direct and alternating. Recall that at a constant current, electrons in electrical circuit they move all the time in one direction, and with alternating current they continuously change direction. What kind of current - alternating or direct - is more needed for technology and industry?

The transmission of electrical energy over long distances is possible only at high voltages, reaching 110, 220, 400 and even 500-800 thousand volts. in. And the generator of an electric station is capable of creating a voltage of no more than 20 thousand volts. in. At the same time, for various electrical machines and apparatuses, an electric current with a voltage of only a few tens or hundreds of volts is needed. This is where alternating current comes in handy. After all, it allows using transformers to easily change the voltage within any limits: increase it at power plants for transmission over long distances and lower it again directly at consumers.

At the end of the last century, the Russian electrical engineer M. O. Dolivo-Dobrovolsky received a three-phase alternating current, which has very important advantages. Firstly, three-phase power lines are more profitable than single-phase ones: more energy can be transmitted through them at the same cost of wires and insulation than single-phase ones. And secondly, thanks to the property of a three-phase alternating current to create a rotating magnetic field, it was possible to build very simple and reliable asynchronous electric motors, which are now widely used to drive machine tools and machines.

These qualities of alternating current allowed him to take a leading position in technology and served as the reason that today all industrial power plants produce only three-phase alternating current.

More than half of the generated electrical energy is consumed by electric motors. In addition to simple asynchronous motors that do not have a winding on the rotor, there are motors with a winding and slip rings on the rotor. Such motors develop great efforts when starting off, and therefore they are most often used on cranes. There are also synchronous motors that have a constant rotation speed. Due to this, they are used in machines and mechanisms that require a constant speed of movement, regardless of their load: in subway escalators, in large water pumps, electric clocks, etc. Electric motors are small, smaller than a spool of thread, and as big as a carousel.

The use of several electric motors to drive machine tools at once made it possible to eliminate a complex transmission system, simplify the mechanisms of machine tools, facilitate their control and make it possible to create automatic lines.

The small size and simplicity of electric motors made it possible to use electrical energy where only manual labor had previously been used. Electric drills, saws, planers, wrenches and other tools have greatly facilitated the work of workers, made it more productive. Electric polishers, vacuum cleaners, washing machines and refrigerators came to the aid of housewives. And even earlier, electric kettles, irons, and stoves appeared in houses.

Alternating current is a good source of heat. Metal is melted and boiled in powerful electric arc furnaces. Electric furnaces are widely used in “artificial climate” installations, for heating drying cabinets and rooms, heating metals, etc.

Electric light bulbs shine regardless of what current flows through their filaments: AC or DC. But AC transmission is more economical, and transformers make it easy to obtain and maintain the required voltage. Therefore, the lighting network of cities and villages is powered by alternating current.

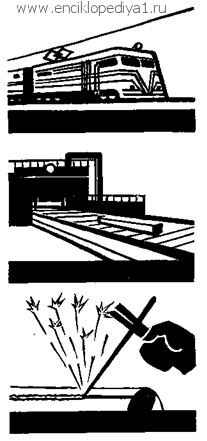

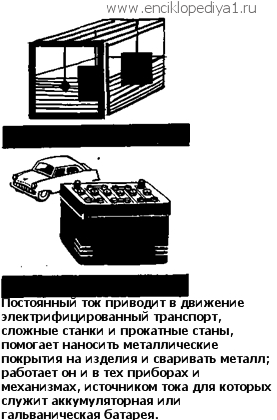

But then we got into a tram, a trolleybus, a subway car, a commuter train - and immediately got into the domain of direct current. The fact is that simple and convenient AC electric motors do not allow you to smoothly change the speed of your rotation. And you have to change the speed of movement almost continuously; only a DC traction motor can do this job well.

But then we got into a tram, a trolleybus, a subway car, a commuter train - and immediately got into the domain of direct current. The fact is that simple and convenient AC electric motors do not allow you to smoothly change the speed of your rotation. And you have to change the speed of movement almost continuously; only a DC traction motor can do this job well.

The power supply of such motors is carried out from special traction rectifier substations, at which alternating current is converted into direct current, and then fed into the contact network - into wires and rails.

But scientists and engineers wondered if it was possible to use alternating current in transport. It turned out it was possible. And already now on many railways in contact wires alternating current flows with a voltage of up to 25 thousand V, and in the future, all railways. But electric locomotive engines still run on direct current: rectifiers that turn alternating current into direct current are also found in electric locomotives in this case.

With the help of DC electric motors, the wheels of diesel locomotives, the mechanisms of rolling mills, walking excavators and many other machines are set in motion.

There is another large and important area in which alternating current cannot compete with direct current. We are talking about electrolysis - a process associated with the passage of current through liquid solutions - electrolytes. Under the action of direct current, the electrolyte decomposes into separate elements, which are deposited on the electrodes lowered into the electrolyte. In this way, aluminum, magnesium, zinc, copper, manganese are obtained. In the chemical industry, fluorine, chlorine, hydrogen and other substances are produced by electrolysis. With the help of electrolysis, protective coatings are applied to metal products (see Art. "").

Direct current successfully competes with alternating current in welding (see the article “How metal is welded”). When welding with direct current, metal particles are transferred from the electrode to the product more correctly and the seam is better than when welding with alternating current.

DC has one more feature. Rather, not at the current itself, but at its sources. To obtain an alternating electric current, it is imperative to set the generator in motion, and a direct current can be provided by stationary batteries and galvanic cells. These properties of electric current sources in some cases make direct current preferred. For example, how to start the engine of a car standing still? It is enough to press the starter button, and the DC motor, receiving power from the battery, will start the engine. And when the engine is running, it spins the generator, which re-charges the battery. Such a reversible process is not available for alternating current.

Many mines operate electric locomotives with batteries, and in the shops of factories, at stations and in warehouses, you can often find small electric carts with batteries - electric cars.

Large batteries are used to power signaling, control and emergency lighting devices in power plants, trains and even trolleybuses. Light accumulators and galvanic batteries are used in portable radio stations, radio receivers, electric lamps, measuring and other devices.

And remember about artificial satellites of the Earth and spaceships: semiconductor solar batteries are installed on them - they also provide a constant electric current (see article "").

Before we finish our story, let us return briefly to its beginning - to the transmission of electrical energy through wires. The transmitted power and the length of power lines are constantly increasing, and it is necessary to increase the voltage to 500 and even up to 800 thousand volts. in.

And it turned out that under these conditions it is more profitable to transmit electrical energy on a direct current. Insulation is used twice as well, the capacity of overhead power lines is increased, the number of wires is reduced ... It is important that there will be no need for a complex synchronization process when switching on lines connecting large power plants or energy systems. This, perhaps, is quite enough to prove the expediency of using direct current for ultra-long-range energy transfers. True, in order to obtain high voltage direct current and then convert it into low voltage alternating current, very complex and expensive converter substations are needed. But, despite this, calculations show that in some cases for heavy-duty and ultra-long-range power transmission it is still more profitable to use direct current. Therefore, work is already underway on the construction of such power lines using direct current.

Of course, the examples listed here are far from exhausting all areas of application of electrical energy. Nothing is said here about its use for telegraph and telephone communications, for radio and television and other purposes, but you will read about this in other articles in this volume. One thing is clear: we need both alternating and direct current, and one of them will never displace the other. On the contrary, the reasonable use of both allows a better and fuller use of electrical energy for the benefit of man.

Alternating current is an electric current that changes in direction and modulus in equal periods. Also, the current that occurs in single-phase and three-phase networks. For existing devices that consume, the AC is converted using special rectifiers.

The occurrence of alternating current

In order for a current to arise in an electrical circuit, special sources are used to generate it, which create a variable electromotive force (EMF). The electromotive force periodically changes in its magnitude and direction. EMF sources are actually alternators.

The simplest AC generation scheme is shown in the figure:

This device consists of two main parts. The fixed part is a magnet that forms a magnetic field between its poles. The density of magnetic field lines is the same, so the magnetic field is uniform. The movable part of the device is a rectangular frame. It is made of copper wire, fixed on a longitudinal axis and rotates in a magnetic field with the help of an external driving force. The output ends are connected with copper slip rings. The rings rotate simultaneously with the frame and slide over the brushes.

To make sure that this device does indeed produce a variable electromotive force, we apply the well-known "right hand rule".

The right hand is positioned in such a way that the palm looks in the direction of the "north" of our magnet. In this case, the thumb is bent towards the movement of that side of the copper frame, where the direction of the EMF should be determined. The direction of the outstretched fingers will show us the direction of the EMF. When determining the EMF in different directions, the value will eventually be common. In addition, with each revolution, the direction of the EMF changes. This is due to the fact that the working sides of the frame during one revolution pass under different poles of the magnet.

The emergence of an electromotive force

The magnitude of the electromotive force that is induced in the frame changes with the speed of crossing the magnetic field lines. In a vertical arrangement - the maximum crossing speed. The EMF in the frame is also the maximum. When the frame passes the horizontal position, the sides do not cross the magnetic field lines, the EMF induction does not  produced.

produced.

From all this it follows that the uniform rotation of the frame provides the induction of the EMF, which uniformly changes in magnitude and direction. The electromotive force generated in the loop eventually creates an alternating current in the external circuit.

We examined the classic scheme for obtaining alternating current. In fact, it is generated using an alternator. Here the electromagnet, on the contrary, rotates and has two or more poles. It's called a rotor. The role of the frame is played by the stator winding (fixed part), from which it is removed AC voltage. For industrial production, generation is carried out using generators of various capacities installed at power plants (hydroelectric power plants, state district power plants, nuclear power plants).

Current is the movement of electrons in a certain direction. It is necessary that electrons also move in our devices. Where does the current come from in the outlet?

The power plant converts the kinetic energy of electrons into electrical energy. That is, a hydroelectric power plant uses running water to turn a turbine. The turbine propeller rotates a ball of copper between two magnets. Magnets make the electrons in the copper move, because of this, the electrons in the wires that are attached to the coil of copper begin to move - a current is obtained.

The generator is like a pump for water, and the wire is like a hose. The generator-pump pumps electrons-water through wires-hoses.

Alternating current is the current that we have in the outlet. It is called variable because the direction of electrons is constantly changing. AC outlets have different frequencies and voltages. What does it mean? In Russian sockets, the frequency is 50 hertz and the voltage is 220 volts. It turns out that in a second the flow of electrons changes the direction of electron movement and charge from positive to negative 50 times. Change of direction can be seen in fluorescent lights when you turn them on. While the electrons are accelerating, it blinks several times - this is the change in direction of movement. And 220 volts is the maximum possible “pressure” with which electrons move in this network.

In alternating current, the charge is constantly changing. This means that the voltage is either 100%, then 0%, then again 100%. If the voltage were 100% constant, then a huge diameter wire would be needed, and with a changing charge, the wires can be thinner. It's comfortable. A power plant can send millions of volts through a small wire, then a transformer for a separate house takes, for example, 10,000 volts, and gives out 220 to each outlet.

Direct current is the current you have in your phone battery or batteries. It is called constant because the direction of electron movement does not change. Charging device transform alternating current from the network to direct current, and already in this form it is in the batteries.

What is alternating current?

Most beginner hams start learning electronics with the basics of direct current (DC), which flows in one direction and/or has a voltage of constant polarity. Direct current is the type of electricity produced by batteries (having positive and negative terminals), or the type of charge produced by friction of certain material types about each other.

However, direct current is not the only kind of electricity. Some power supplies (primarily rotary electromechanical generators) produce voltages that change polarity over time. This type of electricity is known as alternating current (AC):

Just as the familiar battery symbol is used to represent any source of DC voltage, a circle with a wavy line inside is used to represent any source of AC voltage.

One would think that the practical application of alternating current is limited. Indeed, in some cases, alternating current is inferior to direct current in terms of practical application. In systems where electricity is used to dissipate energy in the form of heat, the polarity or direction of the current does not matter - it is sufficient that the voltage and current are sufficient for the load to produce the necessary heat (energy dissipation). However, using alternating current, it is possible to create much more efficient electric generators, electric motors and power distribution systems. Due to this, in high-power systems, the use of alternating current prevails. To understand why this is so, we need to know a little more about alternating current as such.

According to Faraday's law of electromagnetic induction, the electromotive force that arises in a closed conducting circuit is proportional to the rate of change of the magnetic flux through the surface bounded by this circuit. This is the fundamental principle of the alternator, or alternator.

How the alternator works

Notice how the polarity of the voltage on the coils changes when, during rotation, different poles of the magnet appear near them. When connected to a load, such a voltage will create a current that periodically changes its direction of movement. The faster the alternator shaft rotates, the faster the magnet will rotate, and the more often the voltage will change polarity, and the current will change direction over a certain period of time.

Although DC generators operate on the same principle of electromagnetic induction, they are much more complex than their rivals, AC generators. DC generators have a winding on a shaft (alternators have a magnet on the shaft), and this rotating winding is in contact with fixed carbon "brushes". This design is necessary to switch the changing polarity at the output of the coil to an external circuit so that a constant polarity is created on the latter:

The principle of operation of the DC generator

The generator shown in this figure produces two voltage pulses per shaft rotation. Both pulses have the same polarity. For a DC generator to produce permanent voltage, rather than short pulses for each half-cycle of rotation, a set of windings is created that periodically come into contact with the brushes. The figure above shows in simplified form what you will see in practice.

The problems associated with the appearance and interruption of electrical contact during winding movement are obvious (sparking and overheating), especially if the generator shaft rotates at high speed. If the environment around the generator contains flammable or explosive vapors, sparking problems are exacerbated. No brushes or commutators are required to operate an alternator (alternator), so it is immune to the problems inherent in DC generators.

Alternators have obvious advantages over DC generators and when used as electric motors. Unlike DC motors, AC motors do not suffer from the problem of brush contact with the moving winding. Electric motors of direct and alternating current are very similar in their design to the corresponding electric generators.

Thus, it becomes clear that the design of generators and AC motors is much simpler than the design of generators and DC motors. The relative simplicity of these devices in practice translates into much greater reliability and cost-effectiveness. What else is alternating current used for? Surely there must be something else besides using it in generators and electric motors! Indeed, the range of application of alternating current is very wide. Surely you have heard of such a phenomenon as mutual induction. It occurs when two or more windings are placed in such a way that the alternating magnetic field created by one of the windings induces a voltage in the other. If we apply an alternating voltage to one winding, then we also get an alternating voltage to the other. Such a device is known as a transformer.

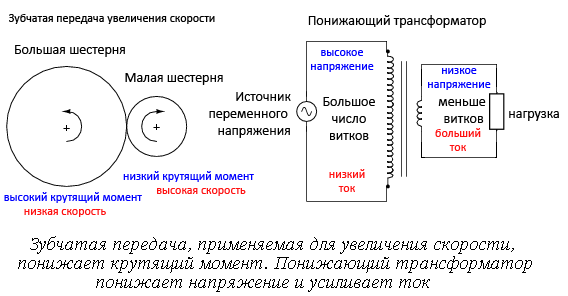

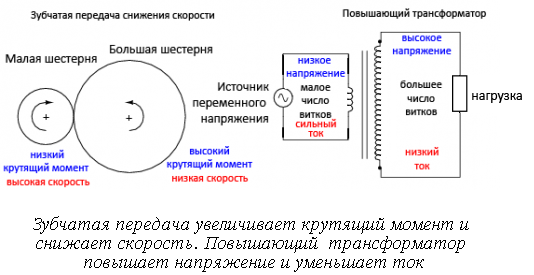

The main purpose of the transformer is its ability to increase and decrease the voltage on the secondary winding. The alternating current voltage appearing in the secondary winding is equal to the alternating current voltage in the primary winding multiplied by the turns ratio factor secondary winding to the number of turns of the primary. If current is supplied from the secondary winding to the load, then the change in current on the secondary winding will be exactly the opposite: the current of the primary winding is multiplied by the ratio of the number of turns of the primary to the number of turns of the secondary winding. The mechanical analogue of such relationships can be an example with torque and speed (instead of voltage and current, respectively):

If the ratio of turns of the windings is reversed, i.e. Since the primary winding has fewer turns than the secondary, the transformer increases the source voltage to a higher level:

The ability of a transformer to step up and step down AC voltage gives AC an undeniable advantage over DC in power distribution (see figure below). It is much more efficient to transmit electricity over long distances when high voltage and low current (smaller diameter wires with lower resistance losses), and then lower the voltage and increase the current while supplying power to end consumers.

Thanks to transformers, the transmission of electrical energy over long distances has become much more practical. Without the ability to effectively increase and decrease the voltage, it would be prohibitively expensive to create power supply systems for long distances (more than a few tens of kilometers).

Transformers require only alternating current to operate. Since the phenomenon of mutual induction is based on alternating magnetic fields, transformers simply will not work on direct current.(direct current can only create permanent magnetic fields). Of course, a direct intermittent (pulsed) current can be applied to the primary winding of the transformer to create an alternating magnetic field (as is done in an automobile ignition system to create a spark in a candle from a low-voltage DC battery), but in this embodiment, a pulsed direct current does nothing. different from variable. Perhaps for this reason, alternating current is more widely used in power systems.