Connecting the electrical panel in the apartment. Electrical panel installation

Distribution board, also called an electrical cabinet, is a box inside which electricity meters, network protection devices and switchgears are installed.

For country houses and small cottages with an area of 150–200 m2, one electrical cabinet is enough, installed at the power input. Inside the box there is a meter, a powerful introductory machine that controls the entire power supply circuit of a country house or cottage, and several smaller circuit breakers.

Usually, one of them controls the socket network, another one controls the lighting network, and the rest are highly specialized and protect specific appliances: a washing machine, an electric stove, an electric heater in a sauna, etc.

Installation of distribution shield is the most important and most responsible part of electrical work in the house. It will be right if you take this process seriously. Reliability depends entirely on the quality of installation electrical network and the operation of its protective devices.

The assembly of electrical panels should ensure the convenience of operating electrical wiring, the possibility of separate control of the power supply of individual groups of consumers in the country, and the selectivity of protection operation. This is possible only with a competent approach to each stage of the installation of the switchboard.

Work begins with the drafting of a power supply project for consumers. Consumers must be grouped by power consumption, by purpose, by the need to install protection, and so on. Consumers include: a kitchen, a living room, a bedroom, a nursery, a sanitary block, an entrance hall, a corridor.

Grouping consumers to combine into separate electrical lines. For individual groups, it is necessary to use RCDs as current protection.

Let's take the project "to the maximum". For him you need:

- Introductory machine - 32A;

- Electric stove - 20A;

- Dishwasher - 16A + RCD 30mA / 25A;

- Kitchen sockets - 16A + UZO 30mA / 25A;

- Kitchen and bathroom lighting - 10A;

- Corridor and hallway lighting - 10A;

- Room lighting - 10A;

- Air conditioning - 16A;

- Sockets - 16A;

- Sockets in the nursery - 16A + UZO 10mA / 20A;

- Washing machine - 16A + RCD 10mA / 20A;

- Water heater - 16A + UZO 10mA / 20A.

It is clear that there are not so many automatic devices and RCDs even in new multi-storey buildings, not like in the country. Here you can combine - for example, hang all the lighting on one machine, sockets in residential premises (in the kitchen, preferably separately and with RCD) on another, etc. RCD can be hung everywhere, but for a water heater, washing machine and dishwasher highly recommended.

As a result, we get:

In my dacha, the wiring is done differently due to the presence street lighting and territorial remoteness of the kitchen, residential building and shower block with utility block. But about this separately.

Electrical panel installation

Before proceeding with the installation electrical panel, you need to decide which type of such equipment suits you best. The internal electrical panel is hidden in the thickness of the wall, and the bill of lading is mounted directly on its surface. Indoor installation equipment takes up much less space, and it looks much more aesthetically pleasing, so it is advisable to choose just such an electrical panel for giving.

The installation of the shield is carried out in several stages. First you need to choose a place suitable for its installation, and then apply markings on the wall. To do this, you need to measure the dimensions of the purchased shield. At the desired height from the floor, draw a horizontal line, and then vertical lines at a distance equal to the width of the electrical equipment plus a margin of 30 mm on each side. After that, draw the second line horizontally at a distance equal to the height of the equipment. But you also need to leave a margin so that the shield can easily fit into the hole prepared for it in the wall.

At the second stage, a hole should be made according to the marked markings. To do this, you will need a puncher and a grinder - a wall chaser. Above or under the electrical panel, it is necessary to make strobes for the outgoing wires and the input cable, then install the base of the shield in the hole prepared for it. To mount the base correctly, you will need a hydraulic level. Using alabaster, you need to make a preliminary fastening. After that, attach the base of the electrical panel with dowel-nails. Usually, similar fasteners are included with the electrical panel. It is recommended to fix the electrical panel at a height of 1.6–1.7 m from the floor, seal the remaining gaps along the perimeter with mounting foam.

To enter the wires into the electrical panel, it is necessary to remove the plugs from the technological holes for their input. You can also lead wires into the shield through the back wall of its base.

After the base is fixed, it is necessary to proceed to the next stage - the assembly of the electrical panel.

Put the DIN rails (metal profile) in the places specially provided for this and fix them with self-tapping screws. After that, install grounding and neutral tires. They come in a variety of modifications. If there is enough space, it is better to install the busbars by attaching them to the DIN rail. The zero bus is installed on insulators. As for the ground bus, it can be fixed without insulators directly to the body of the electrical panel. If the protective and neutral conductors at the input are combined (a two-wire connection scheme is used - phase and PEN conductor), it is necessary to separate the conductors into neutral and protective on the ground bus. A common input PEN conductor is suitable for the ground bus, after which a jumper is installed from it to the zero bus.

When choosing a location for the installation of an electrical panel, two points must be considered. Firstly, after arranging the furniture, it should remain free access, and secondly, it should be located as close as possible to the power supply entering the house.

Then install protection devices. The choice of the rating of the machine will depend on the cross section of the outgoing wires. The electric machine is designed to protect the outgoing line from a short circuit. If its rating is too high, the outgoing wire under high load can become very hot. As a result, it will either fail or cause a fire. Therefore, overrating the machine is a serious fire hazard.

In accordance with the project, it is necessary to install machines in the electrical panel. First install the introductory machine. From it, the wires will go to the group machines of the outgoing lines. The wires should be arranged so that they intersect as little as possible. When stripping wires, it is necessary to make sure that their bare parts do not look out of the terminals of the machines. Groups of machines are interconnected by special jumpers, which are made of wire with the same cross section as the input wire. But in order to make the assembled circuit more reliable, instead of jumpers, you need to install a phase bus.

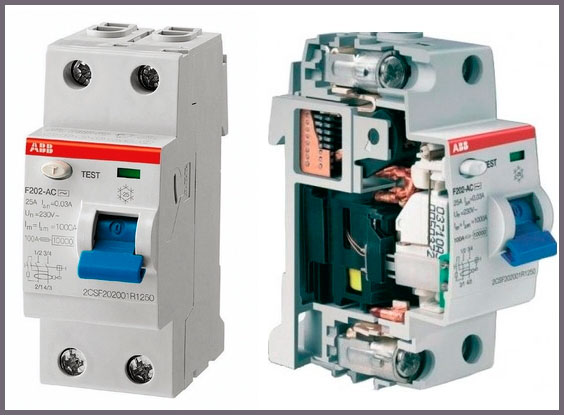

To prevent the possibility of electric shock, it is necessary to install an RCD, since the machine is not able to protect against such a nuisance. Its function is to protect the outgoing line from short circuit. The function of the RCD is precisely to protect against electric shock. It needs to be installed on those lines that go to outlets. Residual current devices are especially needed for lines leading to an electric stove and a washing machine. To connect the RCD, the neutral wire must be taken from the zero bus, and the phase wire from the machine (Fig. 12).

When the load is connected, you should check if there is voltage on the outgoing lines. To do this, it is necessary to turn off the machines on these lines and apply voltage to the electrical panel through the introductory machine. Using a multimeter or tester, make sure that there is voltage on the machines. If everything is functioning normally, the introductory machine is turned off and the final assembly of the electrical panel is started. To do this, install the cabinet cover, mark all the machines, guided by the single-line diagram specified in the project. If the cabinet door is made of opaque material, it is advisable to stick on it with inside copy of the schema. It will be useful in the course of further operation, especially if you need to eliminate any malfunctions. This stage completes the installation and assembly of the electrical panel.

Figure 12. Electrical panel diagram: 1 - introductory machine; 2 - electric meter; 3 - residual current device (RCD); 4 - ground bus; 5 - zero bus; 6, 7, 8, 9 - machines for outgoing lines of lighting and sockets

From the book Living Room author Zhalpanova Liniza ZhuvanovnaGlass installation Glasses are installed in the window frame and fixed with glazing beads or studs. To fix the glass, only small nails and studs are used. They should be driven into the side parts of the folds every 25 cm so that they go slightly up from

From the book Living Room author Zhalpanova Liniza ZhuvanovnaInstallation of skirting boards The last stage of work is fixing the skirting boards. Skirting boards give the wall a finished look, improve the appearance of the floor and close the gaps between the floor and the wall. They can be made from wood and plastic. If the floors are made of linoleum or PVC

From the book Living Room author Zhalpanova Liniza ZhuvanovnaLadder installation Ladder installation begins with the installation of stringers. They are fixed on the surface of the floor of the first floor with screws, and at the top they are attached to the floor beams. The attachment points can be reinforced with metal corners screwed to the floor.

From the book Bedroom authorInstalling glass Install glass in the window frame and secure with glazing beads or studs. To fix the glass, use only small nails and studs. They should be driven into the side parts of the folds every 25 cm so that they go slightly up from

From the book Bedroom author Lyakhova Kristina AlexandrovnaInstallation of skirting boards Skirting boards can be smooth or embossed. For a tighter fit to the floor and walls, a groove or bevel is made in them. Join the skirting boards along the length at a right angle, while in the corners of the room it is necessary to make a cut at an angle of 45 ° and join “at

authorInstallation of skirting boards After gluing the joints of linoleum, skirting boards are installed. Wooden skirting boards are attached to corks in the walls with nails 2.5 mm in diameter and 35–40 mm long or screws 3 mm in diameter and 25 mm long. PVC skirting boards are glued to the walls with KN-2 glue and

From the book The Newest Encyclopedia of Proper Repair author Nesterova Daria VladimirovnaInstalling plumbing You can install plumbing equipment without the help of a plumber, you just need to have the necessary tools on hand and follow some rules. Proper installation of plumbing equipment and devices is the key to their normal

From the book The Newest Encyclopedia of Proper Repair author Nesterova Daria VladimirovnaInstallation of toilets As a rule, ceramic toilets are installed on concrete or tiled floors and fixed with dowels, screws or by gluing to the floor. Between the floor and the toilet, rubber sheet is laid with a hole for the direct outlet of the toilet.

From the book The Newest Encyclopedia of Proper Repair author Nesterova Daria VladimirovnaInstallation of washbasins Ceramic washbasins, single and group, are installed on cast-iron brackets attached to the wall with screws.

From the book Electricity in the country author Pechkareva Anna VladimirovnaInstallation of sockets Before proceeding with the installation of the socket, you need to run the cable to the place where it will be installed. In addition, you need to prepare the necessary tools and materials: a screwdriver, pliers, an impact drill or puncher, a drill bit

From the book Stoves for baths and saunas with their own hands author Kalyuzhny Sergey Ivanovich author Simonov Evgeny Vitalievich From the book Building a house quickly and cheaply author Simonov Evgeny Vitalievich author Nikitko IvanInstallation of beacons Before proceeding with the production of screeds, it is necessary to install the so-called beacons. Without their use, it will be impossible to ensure that the floor surface is perfectly flat and has the required height. This is especially true for large

From the book All about tiles [Do-it-yourself laying] author Nikitko IvanInstallation of ebbs Installation of ebbs is necessary in cases where there is a significant gap between the wall and floor cladding (this often happens, for example, when finishing bathrooms). It is made as follows: at the initial stage, tiles are cut

From the book Home Locksmith author Zvonarev Nikolai MikhailovichInstallation of pipes For gas and water indoor devices, steel pipes are used almost exclusively, and cast iron pipes are used for sewage. Water and gas pipes are connected using couplings, tees, transitions and other threaded fittings. Pipes

I talked about how to completely replace the wiring. We brought all new wiring to one place in the corridor. There was already a metal built-in electrical panel with a meter and an introductory machine. Below this shield, we placed an electrical panel with machine guns.

We laid the wires to the shield in the gate on the side of the counter. Hollowed out a place under the shield for twelve modules. They brought a cable into the body of the shield and froze it with alabaster. After the alabaster hardened, the body of the electrical panel was covered with gypsum plaster.

How to choose an electrical panel

Now we will consider a few general rules for choosing an electrical panel. I’ll make a reservation right away - I’m not a supporter of buying electrical panels in markets and shops like “Everything for Construction”. I buy them either in trusted stores or via the Internet from manufacturers.

- It is better to buy an electrical panel with a small margin of modules. You should always be able to maneuver in a big way. For example, when we calculated the replacement of wiring, we planned a shield for eight modules. Set to twelve. In the process of assembling the shield, they regretted that they had not bought sixteen modules.

- Try not to skimp on the shield. Cheap shield - cheap plastic. Over time, it may turn yellow and become brittle. Also, manufacturers of cheap shields do not take into account such shield qualities as: self-extinguishing and low smoke.

- Shields from well-known manufacturers are already sharpened for competent, convenient and safe cabling inside them. An inexpensive shield bought on the market will probably have to be tuned and understaffed.

Electrical panel device

Initially, it was planned to install one RCD and six automatic machines in our shield. And then, the customer was perplexed, for which there were six automatic machines for two rooms and a kitchen. Previously, everything worked from two traffic jams.

I explain to him: there was no air conditioning before, a boiler was bought instead of the old gas column, the washing machine was connected through an extension cord in the room along with the TV. Plus, in the bathroom there was a brand new, not yet connected shower box with lights, radio and other gadgets. And somewhere you need to connect a couple of dozen sockets and a dozen light bulbs.

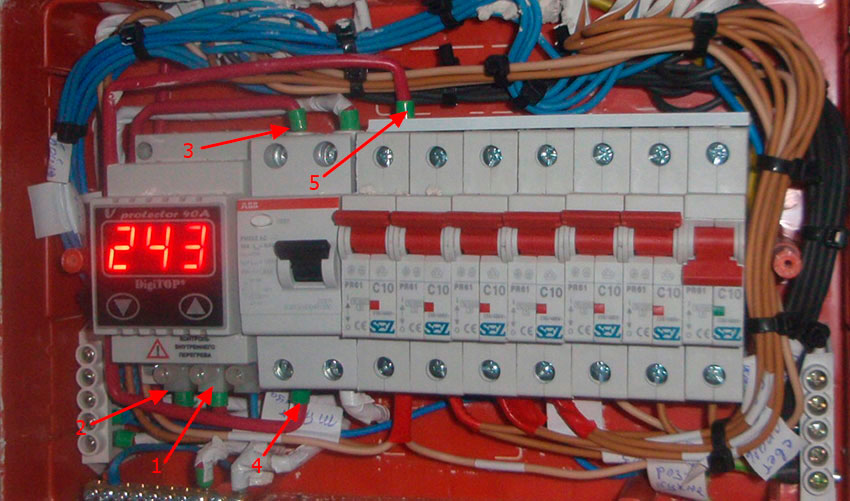

As a result, we decided as follows: we give three machines for sockets and lighting, and four machines for a boiler, shower, air conditioning and a washing machine.

![]()

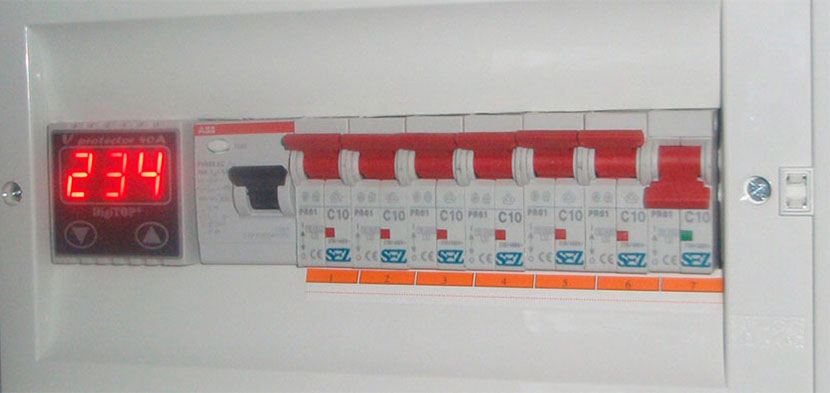

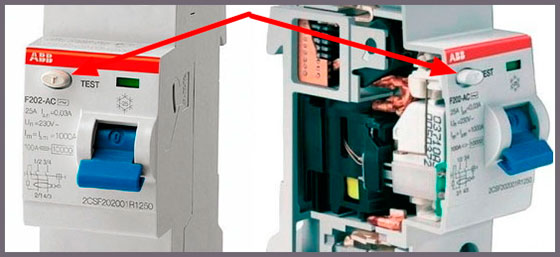

RCD rules over the machines. Protective Shutdown device or differential relay (difrel). Turns off everything at the slightest attempt of electric current to go to the side or to your hands. An essential piece in your shield.

Above all this is a voltage relay. Controls the input voltage. The voltage jumped in your network, for example, up to 260V. Clack! The relay turned off all the equipment. The voltage dropped below 250V. Clack! Enabled. The same goes for the lower limit.

A very useful gadget for your home. Primitive, not very accurate, Chinese. But, but in conjunction with a contactor, it is practically not killed.

How to connect a phase in an electrical panel

- Input to the phase voltage relay from the meter.

- Phase output from voltage relay to RCD.

- Input to RCD phase with voltage relay.

- Phase output from RCD to machines.

- Entrance to phase machines with RCD.

Electric current from the meter is supplied to the voltage relay. If the voltage of the electric current corresponds to the specified parameters of the relay, the current is supplied to the RCD. With RCD, electric current is supplied to circuit breakers.

How to connect zero in the electrical panel

When buying, the shield was completed with one zero tire. I had to additionally buy a pair of zero tires in isolation.

We used one of these tires for wiring zero after the RCD. The second is for grounding.

- Zero from the counter comes to an uninsulated zero bus from the shield kit.

- From the same bus, zero goes to the RCD.

- Zero input to the RCD.

- Zero exit from the RCD.

- Connecting a zero with an RCD to a zero bus for distributing consumers.

- Zero connection to power the voltage relay.

Zero is divided into two groups. The first group is used to connect the input, RCD and voltage relay. The second is for connecting zero conductors of all lines. The wires are assembled in three pieces and crimped with cable lugs. How to crimp the wires is shown below.

Attention! Do not use too much force to tighten the screws in the tires. Otherwise, you can cut the wires with screws.

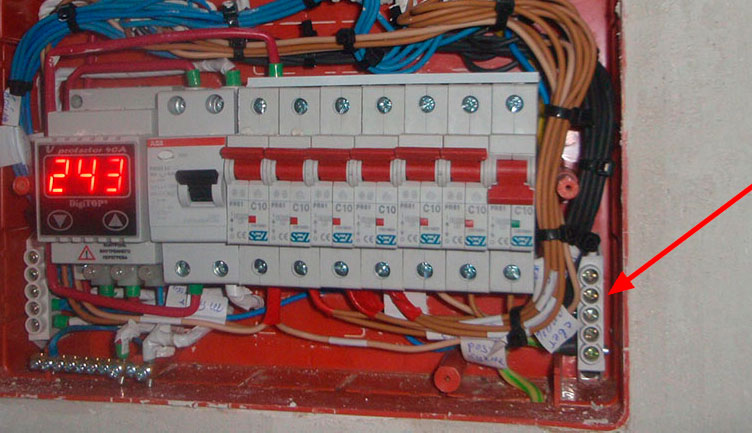

How to connect the ground in the electrical panel

We placed the bus for connecting PE conductors in the lower right corner. We fasten the zero tire directly to the shield with self-tapping screws.

As well as at zero, we crimp three wires into one tip and connect to the bus.

In addition, I would like to draw your attention to the land. In my case, initially there was a correct grounding. If you do not have a ground loop or you are not sure about something, it is better to play it safe and consult with specialists.

Attention! Neglect grounding and zeroing is a direct threat to the life of you and your loved ones.

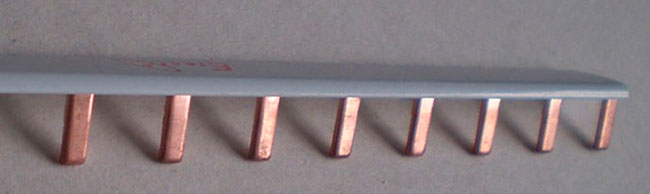

How to connect machines in the electrical panel

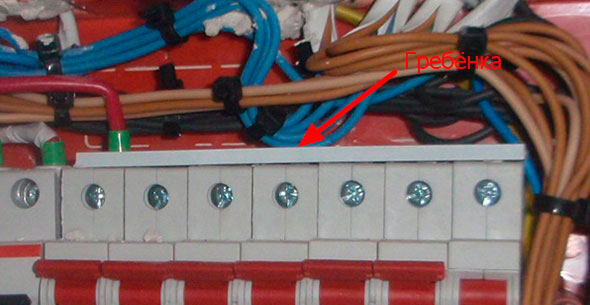

From above we connect the machines with a connecting comb.

Many people prefer to make jumpers between machines from a wire. I think the comb is more reliable. And aesthetics are second to none.

When buying a comb, pay special attention to its weight and thickness. Many manufacturers maintain low prices for combs by reducing the section. The cross section of the core in the comb must be at least 10 mm / sq.

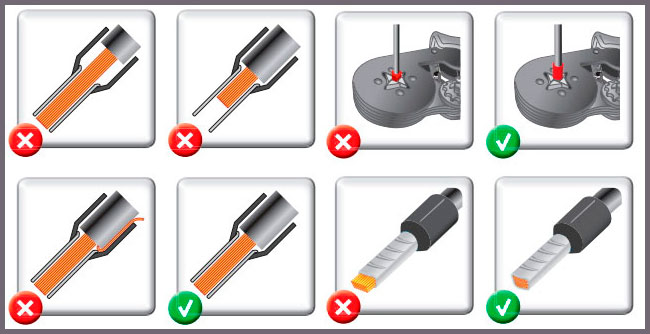

From below, we start wires from consumers into the machines. In some machines we start two wires. It is allowed to clamp up to three wires under one clamp. Stranded wires are crimped with cable lugs.

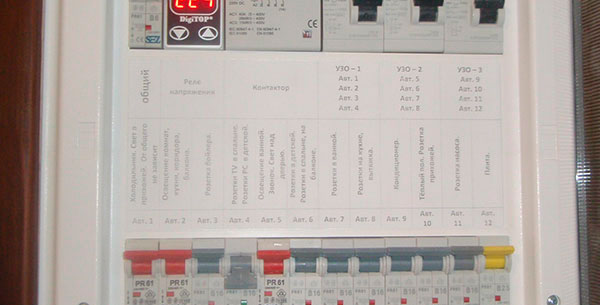

How to sign machines in the electrical panel

The next step is equally important. You need to sign the machines, which one, what turns it off.

Each shield comes with a self-adhesive label. There are either empty cells on it, or serial numbers of automata. Not very comfortable things. There is very little space for a normal description of the machine. Many years pass and no one will remember what “roz.com.2” means. Therefore, in this case, I just had to number the machines.

Then, on a piece of paper made up detailed description. This paper was glued in a shield with a counter, on the inside of the door.

If the design of the shield allows, you can stick the description directly on the shield.

This is done easily.

- We make a table. I do it in Word, right away in the right size.

- Let's print it out.

- The front side is laminated with transparent tape.

- Glue double-sided tape on the reverse side.

- Under the ruler with a sharp knife or blade, cut out the table.

- We tear off the protective film on the double-sided tape and glue the table on the shield.

How to maintain an electrical panel

The electrical panel must be serviced regularly. Its performance and the safety of your home depend on it.

- Six months after the assembly and connection of the shield, it is necessary to carry out a control broach of the contacts of the machines and tires.

- In the future, this procedure is carried out annually.

- Every two weeks it is necessary to test the RCD. To do this, press the "TEST" button on the device. Testing is best done in the morning when most electrical appliances are turned off.

Attention! Do not use too much force to tighten the screws in the tires

P.S. What if you need advice or advice?

- Ask a question on the Electro-Plumbing forum.

- call me on

- Ask your question on social networks -