Adjustable voltage regulator on lm317 circuit. Voltage regulator on LM317

The LM317 adjustable three-terminal positive voltage regulator provides a load current of 100mA over an output voltage range of 1.2V to 37V. The regulator is very easy to use and requires only two external resistors to provide the output voltage. In addition, the voltage and current instability of the LM317L stabilizer has better performance than traditional stabilizers with a fixed output voltage value.

The advantage of the LM317L IC is also that it is available in a standard TO-92 transistor package, which is convenient for installation and installation. In addition to improved performance over conventional fixed-output voltage regulators, the LM317L has all of the IC-only protections available, including built-in internal current limiting, overheating, and safe area correction. work.

All regulator overload protection functions also when the control output (ADJ) is disconnected. Under normal operating conditions, the LM317LHe regulator requires the connection of additional capacitors, except when the regulator IC is installed far from the primary power filter capacitor; in such a situation, an input shunt capacitor is required. An alternative output capacitor improves the performance of transients in the stabilizer, and shunting the control output of the IC by the capacitor increases the value of the voltage ripple smoothing factor, which is difficult to achieve in other known three-terminal stabilizers.

In addition to replacing traditional fixed voltage regulators, the LM317 is suitable for a wide range of possible applications. So, in particular, the "floating" mode of operation of the stabilizer according to the real drop in the output voltage, in which the IC is affected only by the difference between the input and output voltage, allows it to be used in circuits with a high-voltage stabilized power supply, and the operation of the stabilizer in such a circuit can continue indefinitely , as long as the difference between the input and output voltage does not exceed the maximum allowable value.

In addition, the LM317 is useful for building very simple adjustable switching regulators, programmable output regulators, or for creating a precision current regulator based on the LM317 by connecting a fixed resistor between the control and output pins of the IC. The creation of secondary power supplies that remain operational during episodic short circuits of the output circuits is possible due to fixing the voltage level at the control output of the IC relative to ground, which programs the output voltage to be held at 1.2 V (for this voltage level, the current is quite small for the vast majority of types of loads ). The LM317L IC is produced in a standard TO-92 transistor package and operates in a temperature range of -25 ... +125 "C.

Scheme charger on LM317 is shown below. It uses the charging method. direct current. The charge current depends on the resistance R1. The resistance rating must be in the range from 0.8 ohms to 120 ohms, which is equal to the charging current from 10 mA to 1.56 A:

Stabilized 5 Volt power supply with electronic switching:

15 volt power supply with soft start. The necessary smoothness of switching on is set by the capacitance level of capacitor C2:

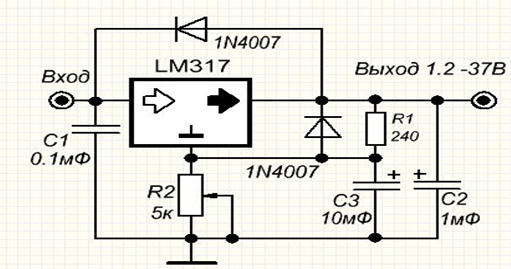

Scheme of an adjustable power supply for 2-30 Volts on the LM317

The output voltage can be adjusted from 1.2 to 37 volts.

A powerful Darlington transistor Q1 is needed to increase the current of the LM317, because without a heat sink, the microassembly can only output 100 mA current, but it is quite enough to drive the transistor. D1 and D2 are protective diodes against overcharging of capacitances. 100 nF capacitors are installed in parallel with electrolytic capacitors to reduce RF noise. It is desirable to put the transistor Q1 on a radiator, the maximum output power of the PSU is 125 watts.

This circuit limits the current and ensures the normal operation of the LED. This driver can drive 0.2-5 watt LEDs from 9-25 volts

Not without the help of a transformer, we lower the voltage from a change of 220 Volts to 25 Volts (you can use a transformer for another voltage convenient for you), then AC voltage turns into a constant with the spell "diode bridge" and smoothed by capacitor C1, then to a highly stable voltage regulator

If you decide to convert your vehicle to LED lightening, you will need at least a lm317 current regulator for the LEDs. It is not difficult to assemble an elementary stabilizer, but in order to avoid deplorable oversights, even with such a simple task, a minimum educational program will not interfere. Many people who are not related to radio electronics often confuse concepts such as a current stabilizer and a voltage stabilizer.

Easy about simple. Current strength, voltage and their stabilization

The voltage determines how fast the electrons move through the conductor. Many hardcore overclockers increase the core voltage of the CPU to make it run faster.

The current strength is the density of the movement of electrons inside an electrical conductor. This parameter is extremely important for radio elements operating on the principle of thermionic secondary emission, in particular, for light sources. If the cross-sectional area of the conductor is not able to pass the flow of electrons, the excess current begins to be released as heat, causing the part to overheat significantly.

For a better understanding of the process, let's analyze the plasma arc (on its basis, the electric ignition of gas stoves and boilers works). At very high voltage the speed of free electrons is so high that they can easily "fly" the distance between the electrodes, forming a plasma bridge.

And this is an electric heater. When electrons pass through it, they transfer their energy to the heating element. The higher the current strength, the denser the electron flow, the stronger the thermoelement heats up.

What is the need for stabilization of current and voltage

Any electronic component, whether it be a light bulb or a computer's central processing unit, requires a clearly limited number of electrons that flow through the conductors for optimal operation.

Since we are talking about a stabilizer for LEDs in our article, we'll talk about them.

With all their advantages, LEDs have one drawback - high sensitivity to power parameters. Even a moderate excess of force and voltage can lead to burnout of the light emitting material and failure of the diode.

Now it is very fashionable to remake the car lighting system under LED lighting. Their color temperature is much closer to natural light than that of xenon and incandescent lamps, which is much less tiring for the driver on long trips.

However, this solution requires a special technical approach. The nominal supply current of a car LED diode is 0.1-0.15 mA, and the starting battery is hundreds of amperes. This is enough to burn out a lot of expensive lighting elements. To avoid this, use a 12 volt stabilizer for LEDs in a car.

The amperage in the automotive network is constantly changing. For example, a car air conditioner “eats” up to 30 amperes, when it is turned off, the electrons “allocated” for its work will no longer return back to the generator and battery, but will be redistributed among other electrical appliances. If an additional 300 mA does not play a role for an incandescent lamp rated for 1-3 A, then several such jumps can be fatal for a diode with a supply current of 150 mA.

For the sake of guaranteeing long-term operation of automotive LEDs, a current stabilizer on lm317 is used for high-power LEDs.

Types of stabilizers

According to the method of limiting the current, two types of devices are distinguished:

- Linear;

- Pulse.

It works on the principle of a voltage divider. It releases a current of a given parameter, dissipating the excess in the form of heat. The principle of operation of such a device can be compared with a watering can equipped with an additional drain hole.

Advantages

- affordable price;

- simple installation scheme;

- easy to assemble by hand.

The disadvantage is that due to heating it is poorly adapted to work with a large load.

How a vegetable cutter cuts the incoming current through a special cascade, giving out a strictly metered rate.

Advantages

- designed for high loads;

- does not heat up during operation.

Flaws

- requires a power source for its own operation;

- creates electromagnetic radiation;

- relatively high price;

- difficult to make yourself.

Given the low current strength in automotive LEDs, you can assemble a simple do-it-yourself LED stabilizer. The most affordable and simple driver LED lamps and tapes are assembled on the lm317 chip.

Brief description of lm317

The LM317 radio electronic module is a microcircuit used in current and voltage stabilization systems.

- The voltage stabilization range from 1.7 to 37 V will provide a stable brightness of the LED, independent of the engine speed;

- Support for output current up to 1.5 A will allow you to connect several photo emitters;

- High stability allows output fluctuations of only 0.1% of nominal;

- It has built-in current limiting protection and overheating shutdown cascade;

- The microcircuit housing is the ground, therefore, when fastened with a self-tapping screw to the car body, the number of mounting wires is reduced.

Application area

- Voltage and current stabilizer for LEDs at home (including for LED strips);

- Voltage and current stabilizer for LEDs in cars;

Current stabilizer circuits for LEDs

Scheme of the simplest stabilizer

Scheme of the simplest stabilizer The simplest voltage regulator for 12 volts can be assembled according to this scheme. Resistor R1 limits the output current, R2 limits the output voltage. The capacitors used in this circuit reduce voltage ripple and increase stability.

The needs of the motorist will be satisfied by the simplest stabilization mechanism, since the supply voltage in the car's network is quite stable.

To make a stabilizer for diodes in a car, you will need:

- Chip lm317;

- Resistor as a current regulator for LEDs;

- Soldering and mounting tools.

We collect according to the above scheme

Resistor Calculation for LED Driver

The power and resistance of the resistor is calculated based on the current strength of the power source and the current, required by the LEDs. For a car LED with a power of 150 mA, the resistance of the resistor should be 10-15 ohms, and the calculated power should be 0.2-0.3 watts.

How to assemble with your own hands, see the video:

The availability and simplicity of the design of the driver on the lm317 chip allows you to painlessly re-equip the electric lighting systems of any car.

In amateur radio practice, microcircuits of adjustable stabilizers are widely used. LM317 and LM337. They have earned their popularity due to their low cost, availability, easy-to-install design, and good parameters. With a minimum set of additional parts, these microcircuits allow you to build a stabilized power supply with an adjustable output voltage from 1.2 to 37 V at a maximum load current of up to 1.5A.

But! It often happens that with an illiterate or inept approach, radio amateurs fail to achieve high-quality operation of microcircuits, to obtain the parameters declared by the manufacturer. Some manage to drive microcircuits into generation.

How to get the most out of these microcircuits and avoid common mistakes?

About this in order:

Chip LM317 is an adjustable stabilizer POSITIVE voltage, and the microcircuit LM337- adjustable stabilizer NEGATIVE voltage.

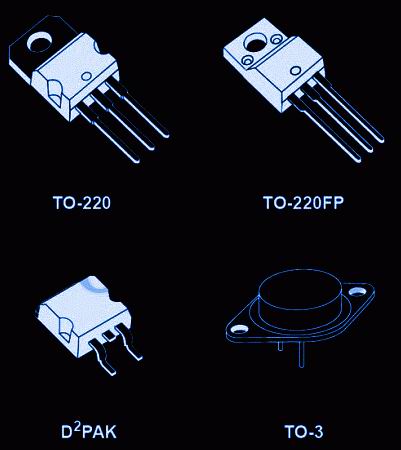

I draw special attention to the fact that the pinouts of these microcircuits various!

Zoom on click

The output voltage of the circuit depends on the value of the resistor R1 and is calculated by the formula:

Uout=1.25*(1+R1/R2)+Iadj*R1

where Iadj is the control output current. According to the datasheet, it is 100 μA, as practice shows, the real value is 500 μA.

For the LM337 chip, you need to change the polarity of the rectifier, capacitors and output connector.

But the meager datasheet description does not reveal all the intricacies of using these microcircuits.

So, what does a radio amateur need to know to get from these microcircuits MAXIMUM!

1. To get the maximum suppression of input voltage ripple, you must:

- Increase (within reasonable limits, but at least up to 1000 uF) the capacitance of the input capacitor C1. By suppressing the ripple at the input as much as possible, we get a minimum of ripple at the output.

- Shunt the control output of the microcircuit with a 10 microfarad capacitor. This increases ripple suppression by 15-20dB. Setting the capacity more than the specified value does not give a tangible effect.

The scheme will take the form:

2. With output voltage more than 25V in order to protect the microcircuit , for fast and safe discharge of capacitors, it is necessary to connect protective diodes:

Important: for LM337 microcircuits, the polarity of the diodes must be reversed!

3. To protect against high-frequency interference, electrolytic capacitors in the circuit must be shunted with small film capacitors.

We get the final version of the scheme:

Zoom on click

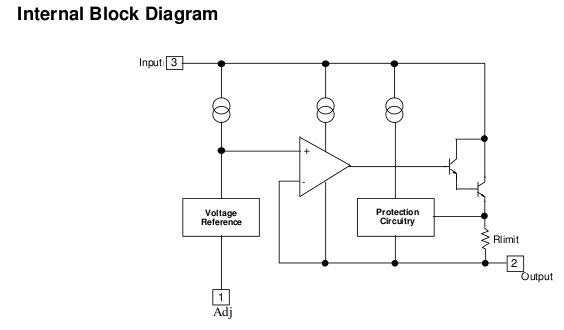

4. If you look internal structure of microcircuits, you can see that 6.3V zener diodes are used inside in some nodes. So the normal operation of the microcircuit is possible at the input voltage not lower than 8V!

Although the datasheet says that the difference between the input and output voltages should be at least 2.5-3 V, how the stabilization occurs when the input voltage is less than 8V, one can only guess.

5. Particular attention should be paid to the installation of the microcircuit. The diagram below shows the wiring diagram:

Zoom on click

Explanations for the scheme:

- length of conductors (wires) from the input capacitor C1 to the input of the microcircuit (A-B) should not exceed 5-7 cm. If for some reason the capacitor is removed from the stabilizer board, it is recommended to install a 100 uF capacitor in the immediate vicinity of the microcircuit.

- to reduce the effect of the output current on the output voltage (increasing current stability), resistor R2 (point D) must be connected directly to the output pin of the microcircuit or separate track/conductor ( section C-D). Connecting resistor R2 (point D) to the load (point E) reduces the stability of the output voltage.

- the conductors to the output capacitor (C-E) should also not be made too long. If the load is far away from the stabilizer, then on the load side it is necessary to connect a bypass capacitor (100-200 uF electrolyte).

- also, in order to reduce the influence of the load current on the stability of the output voltage, the "ground" (common) wire must be separated "star" from the common terminal of the input capacitor (point F).

Successful creativity!

14 comments on “LM317 and LM337 adjustable stabilizers. Application Features”

- Chief Editor:

August 19, 2012Domestic analogues of microcircuits:

LM317 - 142EN12

LM337 - 142EN18

The 142EN12 chip was produced with different pinout options, so be careful when using them!

Due to the wide availability and low cost of original microcircuits

Better not to waste time, money and nerves.

Use LM317 and LM337.

- Sergei Khraban:

March 9, 2017Hello, dear Editor-in-Chief! I am registered with you and I also really want to read the entire article, study your recommendations on the use of LM317. But, unfortunately, something I can not view the entire article. What do I need to do? Please give me a complete article.

Sincerely, Sergey Khraban

- Chief Editor:

March 10, 2017Now happy?

- Sergei Khraban:

March 13, 2017I am very grateful to you, thank you very much! All the best!

- Oleg:

July 21, 2017Dear Chief Editor! I assembled two polar explorers on lm317 and lm337. Everything works fine except for the difference in tension in the shoulders. The difference is not great, but there is sediment. Could you tell me how to achieve equal voltages, and most importantly, what is the reason for such a bias. Thank you in advance for your answer. With wishes of creative success Oleg.

- Chief Editor:

July 21, 2017Dear Oleg, the difference in tension in the shoulders is due to:

2. deviation of the values of the setting resistors. It should be remembered that resistors have tolerances of 1%, 5%, 10% and even 20%. That is, if 2 kOhm is written on the resistor, its actual resistance can be in the region of 1800-2200 Ohm (with a tolerance of 10%)

Even if you put multi-turn resistors in the control circuit and use them to accurately set the required values, then ... when the temperature changes environment tension will still float. Since the resistors are not the fact that they will warm up (cool down) the same way or change by the same amount.

You can solve your problem by using op-amp circuits that monitor the error signal (output voltage difference) and make the necessary correction.

Consideration of such schemes is beyond the scope of this article. Google to the rescue.

- Oleg:

July 27, 2017Dear editor! Thank you for the detailed answer, which prompted clarifications - how critical is power supply with a difference in the shoulders of 0.5-1 volt for ULF, preliminary cascades? Regards, Oleg

- Chief Editor:

July 27, 2017The voltage difference in the arms is primarily fraught with asymmetric signal limitation (at high levels) and the appearance of a constant component at the output, etc.

If the path does not have isolation capacitors, then even a slight constant pressure, which appeared at the output of the first cascades, will be repeatedly amplified by subsequent cascades and will become a significant value at the output.

For power amplifiers powered by (usually) 33-55V, the voltage difference in the arms can be 0.5-1V, for pre-amplifiers it is better to keep within 0.2V.

- Oleg:

August 7, 2017Dear editor! Thank you for your detailed, thorough replies. And, if I may, another question: Without load, the voltage difference in the arms is 0.02-0.06 volts. When the load is connected, the positive shoulder is +12 volts, the negative is -10.5 volts. What is the reason for this shift? Is it possible to adjust the equality of the output voltages not at idle, but under load. Regards, Oleg

- Chief Editor:

August 7, 2017If everything is done correctly, then the stabilizers must be adjusted under load. The MINIMUM load current is indicated in the datasheet. Although, as practice shows, it turns out at idle.

But the fact that the negative shoulder sags as much as 2B is wrong. Is the load the same?

There are either installation errors, or the left (Chinese) microcircuit, or something else. No doctor will make a diagnosis by phone or correspondence. I can't heal from a distance either!

Did you notice that LM317 and LM337 have different pin arrangement! Maybe this is the problem?

- Oleg:

August 8, 2017Thank you for your reply and patience. I'm not asking for a detailed answer. We are talking about possible reasons, nothing more. Stabilizers need to be adjusted under load: that is, conditionally, I connect a circuit to the stabilizer that will be powered from it and set equal voltages in the shoulders. Do I understand the process of setting the stabilizer correctly? Regards, Oleg

- Chief Editor:

August 8, 2017Oleg, not really! So you can burn the scheme. At the output of the stabilizer, you need to attach resistors (of the required power and rating), adjust the output voltages, and only after that connect the powered circuit.

According to the datasheet, the LM317 has a minimum output current of 10mA. Then, with an output voltage of 12V, you need to hang a 1kΩ resistor on the output and adjust the voltage. At the input of the stabilizer, there must be at least 15V!

By the way, how are the stabilizers powered? From one transformer / winding or different ones? When the load is connected, the minus sags by 2V - but how are things at the input of this shoulder?

- Oleg:

August 10, 2017Good health, dear editor! Trans wound himself, at the same time two windings with two wires. The output on both windings is 15.2 volts. On filter capacitors of 19.8 volts. Today, tomorrow I will conduct an experiment and unsubscribe.

By the way, I had an incident. I assembled a stabilizer for 7812 and 7912, powered them with tip35 and tip36 transistors. As a result, up to 10 volts, the voltage regulation in both arms went smoothly, the voltage equality was ideal. But above... it was something. The voltage was regulated by jumps. And rising in one shoulder, in the second it went down. The reason turned out to be tip36, which I ordered in China. I replaced the transistor with another one, the stabilizer began to work perfectly. I often buy parts in China and came to the following conclusion: You can buy, but you need to choose suppliers who sell radio components made in factories, and not in the shops of some incomprehensible individual entrepreneur. It comes out a little more expensive, but the quality is appropriate. Regards, Oleg.

- Oleg:

August 22, 2017Good evening, dear editor! Only today there was time. Trance with a midpoint, the voltage on the windings is 17.7 volts. I hung resistors of 1 kw 2 watts at the output of the stabilizer. The voltage in both shoulders set 12.54 volts. I disconnected the resistors, the voltage remained the same - 12.54 volts. I connected the load (10 pieces of ne5532), the stabilizer works fine.

Thank you for your advice. Regards, Oleg.

Add a comment

Spammers, do not waste your time - all comments are moderated!!!

All comments are moderate!

You must to leave a comment.

Component references (or datasheets) are essential

in the development of electronic circuits. However, they have one, but an unpleasant feature.

The fact is that the documentation for any electronic component (for example, a microcircuit)

should always be ready before this chip is released.

As a result, we actually have a situation where microcircuits are already on sale,

and yet not a single product based on them has been created.

And, therefore, all the recommendations and especially the application schemes given in the datasheets,

are theoretical and recommendatory in nature.

These circuits mainly demonstrate the working principles of electronic components,

but they have not been tested in practice and should therefore not be blindly taken into account

during development.

This is a normal and logical state of affairs, if only over time and as

accumulating experience, changes and additions are made to the documentation.

Practice shows the opposite - in most cases, all circuit solutions,

given in the datasheet remain at the theoretical level.

And, unfortunately, often these are not just theories, but blunders.

And even more regrettable is the discrepancy between the real (and most important)

chip parameters stated in the documentation.

As a typical example of such datasheets, here is a guide to the LM317,-

three-pin adjustable stabilizer voltage, which, by the way, is produced

already 20 years old. And the schemes and data in his datasheet are still the same ...

So, the shortcomings of the LM317, like microcircuits and errors in the recommendations for its use.

1. Protective diodes.

Diodes D1 and D2 serve to protect the regulator, -

D1 for input short circuit protection and D2 for over discharge protection

capacitor C2 "through the low output impedance of the regulator" (quote).

In fact, diode D1 is not needed, since there is never a situation where

The voltage at the input of the regulator is less than the voltage at the output.

Therefore, diode D1 never opens, and therefore does not protect the regulator.

Except, of course, the case of a short circuit at the input. But this is an unrealistic situation.

Diode D2 can open, of course, but capacitor C2 discharges just fine

and without it, through the resistors R2 and R1 and through the load resistance.

And somehow there is no need to specifically discharge it.

Also, the mention in the Datasheet of "discharge C2 through the output of the regulator"

nothing more than an error, because, as the circuit of the output stage of the regulator -

This is an emitter follower.

And the capacitor C2 simply cannot be discharged through the output of the regulator.

2. Now - about the most unpleasant, namely, the discrepancy between real

electrical characteristics declared.

Datasheets of all manufacturers have an Adjustment Pin Current parameter

(current at the tuning input). The parameter is very interesting and important, determining,

in particular, the maximum value of the resistor in the Adj input circuit.

As well as the value of the capacitor C2. The declared typical current Adj is 50 μA.

Which is very impressive and would completely suit me as a circuit engineer.

If in fact it would not be 10 times larger, i.e. 500 uA.

This is a real discrepancy, tested on chips from different manufacturers.

and for many years.

And it all started with bewilderment - why is it such a low-resistance divider at the output in all circuits?

And that's why it's low-resistance, because otherwise it's impossible to get at the output of LM317

minimum voltage level.

The most interesting thing is that in the technique for measuring the current Adj, the low-resistance divider

the output is also present. Which actually means that this divider is on

in parallel with the electrode Adj.

Only with such a cunning approach can one “fit” into the framework of a typical value of 50 μA.

But this is a rather elegant, but trick. "Special Measurement Conditions".

I understand that it is very difficult to achieve a stable current of the declared value of 50 μA.

So don't write linden in the Datasheet. Otherwise, it is a fraud of the buyer. And honesty is the best policy.

3. More about the most unpleasant.

The Datasheets LM317 has a Line Regulation parameter that defines

operating voltage range. And the range indicated is still not bad - from 3 to 40 volts.

Here is just one small BUT...

The inside of the LM317 contains a current regulator that uses

a zener diode for a voltage of 6.3 V.

Therefore, effective regulation starts with an Input-Output voltage of 7 Volts.

In addition, the output stage of the LM317 is NPN transistor included in the scheme

emitter follower. And on the “buildup” he has the same repeaters.

Therefore, efficient operation of the LM317 at a voltage of 3 V is not possible.

4. About circuits that promise to get an adjustable voltage from zero Volt at the output of the LM317.

The minimum voltage value at the output of the LM317 is 1.25 V.

It would be possible to get even less if it were not for the built-in protection circuit against

short circuit at the output. Not the best plan to say the least...

In other microcircuits, the short circuit protection circuit is triggered when the load current is exceeded.

And in the LM317 - when the output voltage drops below 1.25 V. Simple and tasteful -

the transistor closed itself at a base-emitter voltage below 1.25 V and that's it.

That's why, all application schemes that promise to get the output

LM317 adjustable voltage, starting from zero volts - do not work.

All these circuits suggest connecting the Adj pin through a resistor to the source

negative voltage.

But already when the voltage between the output and the Adj contact is less than 1.25 V

the short circuit protection circuit will operate.

All these schemes are pure theoretical fantasy. Their authors do not know how the LM317 works.

5. The output short circuit protection method used in the LM317 also imposes

known restrictions on the launch of the regulator - in some cases, the launch will be difficult,

since it is not possible to distinguish between short-circuit mode and normal-on mode,

when the output capacitor is not yet charged.

6. Recommendations for capacitor ratings at the output of the LM317 are very impressive, -

this range is from 10 to 1000 uF. What in combination with the value of the output resistance

a regulator of the order of one thousandth of an ohm is complete nonsense.

Even students know that the capacitor at the input of the stabilizer is essential,

to put it mildly, more effective than the output.

7. About the principle of regulating the output voltage of LM317.

LM317 is operational amplifier, in which the regulation

output voltage is carried out on the NOT inverting input Adj.

In other words, through the Positive Feedback Circuit (PIC).

Why is it bad? And the fact that all interference from the regulator output through the Adj input passes inside the LM317,

and then back to load. It’s good that the transmission coefficient along the PIC circuit is less than one ...

And then we would get an autogenerator.

And it is not surprising in this regard that it is recommended to put a capacitor C2 in the Adj circuit.

At least somehow filter out interference and increase resistance to self-excitation.

It is also very interesting that in the POS circuit, inside the LM317,

There is a 30pF capacitor. Which increases the level of ripple on the load with increasing frequency.

True, this is honestly shown on the Ripple Rejection chart. But why this capacitor?

It would be very useful if the regulation was carried out along the chain

negative feedback. And in the value of POS, it only worsens stability.

By the way, with the very concept of Ripple Rejection, not everything is “according to concepts”.

In the conventional sense, this value means how well the regulator

filters the ripple from the INPUT.

And for the LM317, it actually means the degree of its own inferiority

and shows how well the LM317 fights ripples, which itself

takes it from the exit and again drives it inside itself.

In other regulators, regulation is carried out along the chain

Negative feedback, which maximizes all parameters.

8. About the minimum load current for LM317.

The Datasheet specifies a minimum load current of 3.5 mA.

At a lower current, the LM317 is inoperative.

A very strange feature for a voltage stabilizer.

So, it is necessary to monitor not only the maximum load current, but also the minimum one too?

This also means that at a load current of 3.5 mA, the efficiency of the regulator does not exceed 50%.

Thank you so much developers...

1. Recommendations for the use of protective diodes for LM317 are of a general theoretical nature and consider situations that do not happen in practice.

And, since it is proposed to use powerful Schottky diodes as protective diodes, we get a situation where the cost of (unnecessary) protection exceeds the price of the LM317 itself.

2. In Datasheets LM317, the parameter for the current input Adj is incorrect.

It is measured in "special" conditions when connecting a low-resistance output divider.

This measurement method does not correspond to the generally accepted concept of "input current" and shows the inability to achieve the specified parameters during the manufacture of the LM317.

And also it is a deception of the buyer.

3. The Line Regulation parameter is specified as a range from 3 to 40 Volts.

In some application circuits, the LM317 "works" at an input-output voltage of as much as two volts.

In fact, the range of effective regulation is 7 - 40 Volts.

4. All circuits for obtaining an adjustable voltage at the output of the LM317, starting from zero volts, are practically inoperative.

5. The LM317 short circuit protection method is sometimes used in practice.

It's simple, but not the best. In some cases, the start of the regulator will be impossible at all.

7. The LM317 implements a flawed principle of output voltage regulation, -

through a positive feedback loop. It should be worse, but nowhere.

8. The limitation on the minimum load current indicates poor circuit design of the LM317 and clearly limits its use cases.

Summing up all the shortcomings of the LM317, recommendations can be made:

a) To stabilize constant "typical" voltages of 5, 6, 9, 12, 15, 18, 24 V, it is advisable to use three-pin stabilizers of the 78xx series, and not LM317.

b) To build really effective voltage regulators, you should use microcircuits like LP2950, LP2951, capable of operating at an input-output voltage of less than 400 millivolts.

Combined with powerful transistors when needed.

The same microcircuits effectively work as current stabilizers.

c) In most cases, an operational amplifier, a zener diode and a powerful transistor (especially a field effect transistor) will give much better parameters than an LM317.

And certainly - the best adjustment, as well as the widest range of types and values of resistors and capacitors.

G). And, don't blindly trust Datasheets.

Any microcircuits are made and, characteristically, sold by people ...