lc connector. Optical LC connectors for high-density mounting

Often familiar system administrators who have not encountered optical fiber before have questions about how and what equipment is needed to organize a connection. After a little reading, it becomes clear that you need an optical transceiver. In this review article, I will write the main characteristics of optical modules for receiving / transmitting information, tell you the main points related to their use, and attach many visual images with them. Beware, there is a lot of traffic under the cut, I took a bunch of my own photos.

What and why

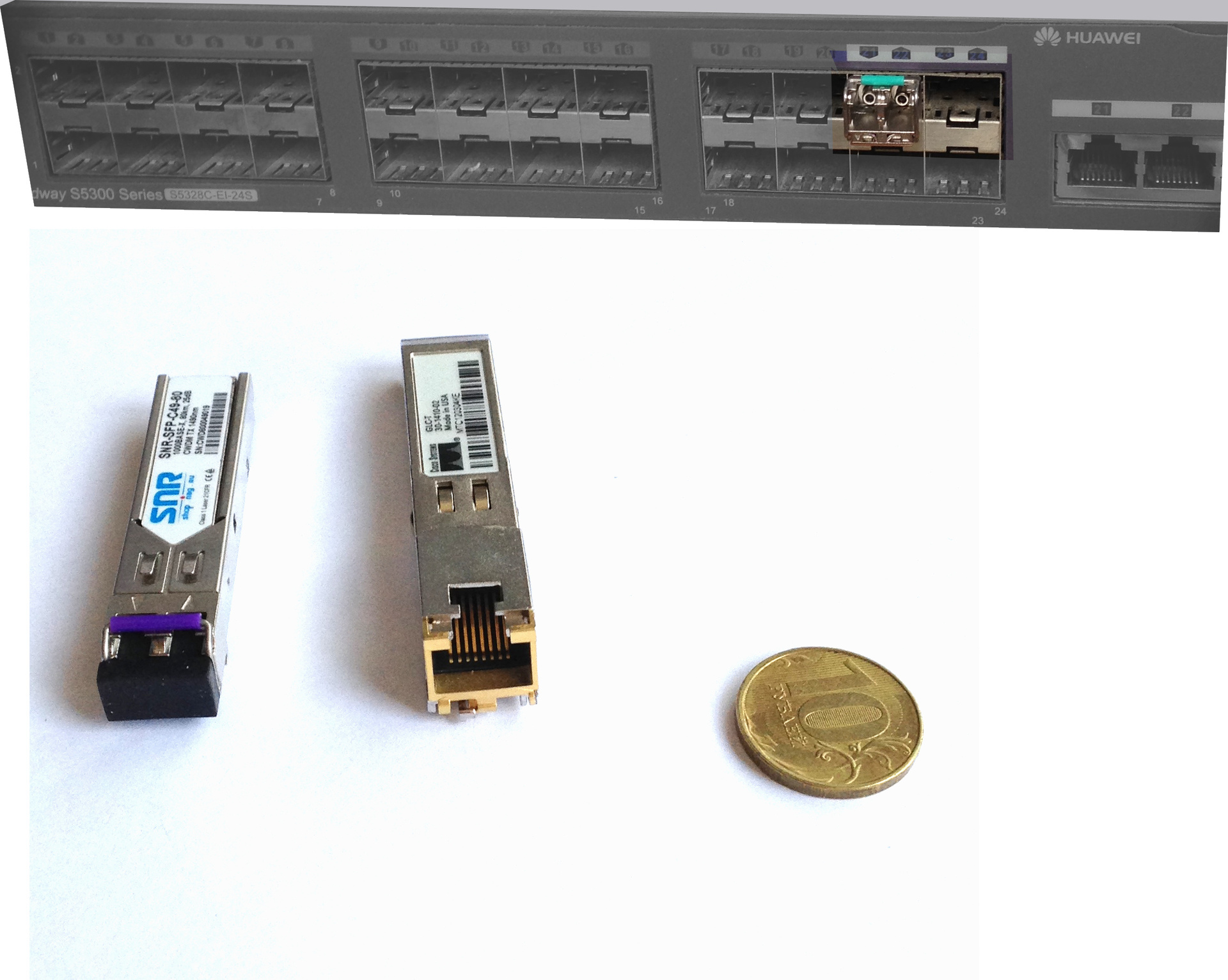

Today, almost any network equipment for data transmission in Ethernet networks that provides the ability to connect via optical fiber has optical ports. Optical modules are installed in them, into which the fiber can already be connected. An optical transmitter (laser) and a receiver (photodetector) are built into each module. In classical data transmission using them, it is supposed to use two optical fibers - one for receiving, the other for transmitting. The image below shows the switch with optical ports and modules installed.

These little electronic gizmos will be discussed further.

Types of optical modules

Periodically, questions arise about what kind of optical transceiver is needed in a particular situation. If there is a price list before your eyes, then your eyes just run up from the abundance of all kinds of names. I will try to clarify what the various letters and numbers mean in the name of the modules and which of them you may need. Optical modules differ in form factor (GBIC, SFP, X2...), technology type ("straight", CWDM, WDM, DWDM...), power (in decibels), connectors (FC, LC, SC).Various form factors

First of all, the modules differ in their form factors. Let me tell you a little about the different options.GBIC

GigaBit Interface Converter, was actively used in the 2000s. The very first industry standardized module format. Very often used for transmission through multimode fibers. Now it is practically not used due to its size. I still have one old tsiska 3500, still without CEF support, in which you can use these modules. The image below shows two 1000Base-LX and 1000Base-T GBIC modules:

SFP

Small Form-factor Pluggable, successor to GBIC. Probably the most common format today, much more convenient due to its smaller size. This form factor has significantly increased the density of ports on network equipment. Thanks to such dimensions, it became possible to implement up to 52 optical ports on one piece of iron in one unit. Used to transfer data at speeds of 100Mbits, 1000Mbits. The image below shows a switch with optical ports and a pair of 1000Base-LX and 1000Base-T modules.

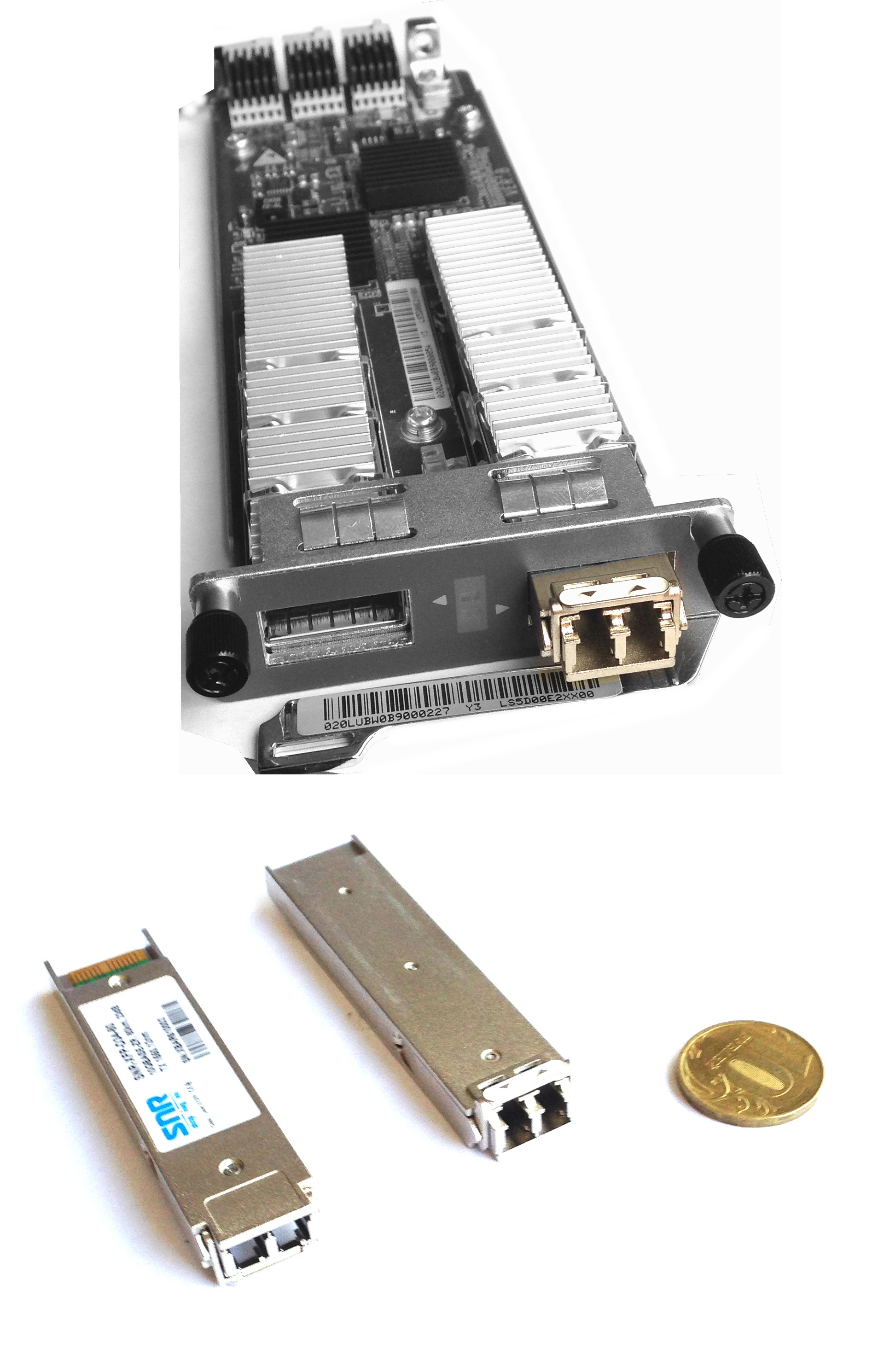

SFP+

Enhanced Small Form Factor Pluggable. They have identical SFP size. The similar size made it possible to make equipment with ports that support conventional SFP and SFP +. Such ports can operate in 1000Base/10GBase modes. Only long-range CWDM modules are longer due to the heatsink. Used to transfer data at speeds of 10 Gbits. The small size gave some features - for long-range modules there are cases of too much heating. Therefore, there are no such modules for transmission over 80 km. In the picture below, there are two SFP + modules - CWDM and a regular 10GEBase-LR:

XFP

10 Gigabit Small Form Factor Pluggable. Also, like SFP +, they are used to transfer data at speeds of 10 Gbits. But unlike the previous ones, a little wider. The increased size allowed them to be used for shooting at long distances compared to SFP +. Below is an additional board for Huawei with XFP installed and a couple of such modules.

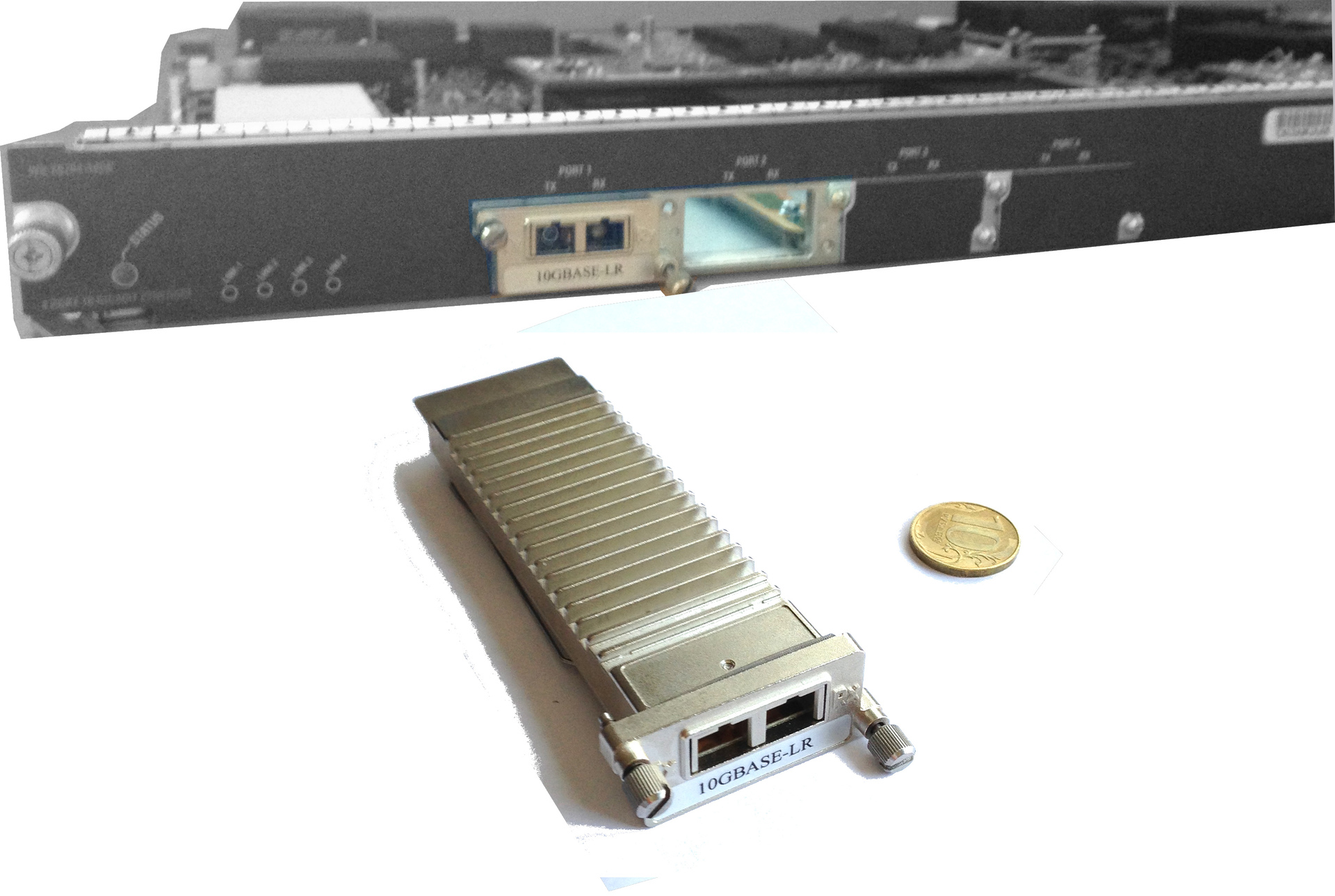

XENPAK

Modules used primarily in Cisco equipment. Used to transfer data at speeds of 10 Gbits. Now they can rarely be used, occasionally they can be found in old lines of routers. Also, such modules are available for connecting a 10GBase-CX4 copper wire. Unfortunately, I found only one 10GEBase-LR XENPAK module and an old Cisco WS-X6704-10GE board for them.

X2

Further development of XENPAK format modules. Often, you can install a TwinGig module in X2 slots, into which you can already install two SFP modules ... This is necessary if the equipment does not have 1GE optical ports. Basically, the X2 form factor is used by Cisco. There are X2-SFP+ (XENPACK-to-SFP+) adapters on sale. Interestingly, such a kit (adapter + SFP + module) is cheaper than one X2 module.Unfortunately, I only had an adapter on hand, but to understand what these modules look like and what size they are, this is quite enough. The picture below shows an X2-SFP+ adapter with an SFP+ module inserted.

But if anyone is interested, here you can see more pictures and the possibilities of this connector.

Yes, I did not touch on relatively new form factors (QSFP, QSFP +, CFP). At the moment they are not very common.

Various standards

As you know, the 802.3 committee has adopted many different Ethernet standards. Accordingly, optical modules support one of them. There is a good cheat sheet on Ethernet standards. The most common types are now:- 100Base-LX - 100 megabits over fiber per 10km

- 100Base-T - 100 megabits over copper over 100 meters

- 1000Base-LX - 1000 megabits over fiber per 10 km

- 1000Base-T - 1000 megabits over copper at 100 m

- 1000Base-ZX - 1000 megabits over single-mode fiber over 70 km

- 10GBase-LR - 10GE over 10km singlemode fiber

- 10GBase-ER - 10GE over single-mode fiber over 40 km

Using WDM

The optical modules described above transmit a signal mainly at a wavelength of 1310 nm or 1550 nm on two fibers (one for transmission, the other for reception). They have a broadband photodetector (they accept everything) and a laser emitting at a certain wavelength (roughly of course). But it is possible to use wavelength compression. This makes it possible to use fewer fibers to organize multiple channels, thereby increasing the throughput of a single fiber.WDM

Such modules work in pairs, on the one hand the signal is transmitted at a wavelength of 1310 nm, on the other 1550 nm. This allows you to use one instead of two fibers to organize one channel. The receiver on such modules remains broadband. There are both for 1GE and 10GE. Below are photos of a pair of WDM modules with different connectors for connecting LC and SC patch cords.

In most cases, it is preferable to use WDM modules for short distances. Their price is not very high (1 thousand rubles per module versus 500 rubles for a regular one). The reason is that you save a whole fiber, it will be possible to run another same channel on it later. Although of course there are other ways to save fiber.

CWDM

Further continuation of WDM technology. With its use, you can achieve up to 8 duplex channels on a single fiber. For these purposes, CWDM multiplexers are used (passive devices with a prism inside, which allows you to divide the signal by color in 20nm steps in the range from 1270nm to 1610nm). For this, special CWDM modules are also used, in the common people they are called “color”, they transmit a signal at a certain wavelength. At the same time, the receiver on them is broadband. In addition, such optical modules are often made for transmission over long distances (up to 160 km). The figure below shows a small CWDM-SFP set, on which, using multiplexers, 2GE can be lifted on a single fiber.

As you can see, everyone's bows are different. Depending on the wavelength, the module has its own coloring. Unfortunately, each manufacturer is different.

Here comes the concept optical budget. True, his calculation is beyond the scope of this article. In short, the more ports available, the more channels you can multiplex, the greater the attenuation. In addition, different wavelengths give different attenuation per 1 kilometer of the transmitted signal. And you also need to consider the type of fiber ...

You can write a lot about the methods for selecting such modules, about the intersection of wavelengths, about unwanted lengths, about ADD / DROP modules. But this is a separate issue.

Connectors

This is where you will connect the optical patch cord. Two types of connectors are currently used on optical modules - SC and LC. Roughly and slangy - large and small squares. It is clear that if you have a patch cord with an SC connector, you will not connect it to the LC connector. You need to either change the patch cord, or install an adapter adapter. In most cases, SFP modules have an LC connector, while X2/XENPAK has a SC connector. Above in the images there were already modules with different connectors.A little about patch cords

Optical patch cords, they are also optical cords. We will be interested in the following characteristics: duplex / simplex (number of fibers), polishing (currently UPC blue or APC green), connector (SC, LC, FC), multimode and length. Of course, the thickness of the core of the fiber is also important, but now standard thickness is used on multimode conventional cords. Below I have presented an image with various types of patch cord ends.

Basically you will meet the following designation of cords - SHO-2SM-SC/UPC-SC/UPC-3.0. It is deciphered as follows: Cord Optical Duplex Single-Mode (Single-Mode) with SC connectors and polished UPC on one side and SC-UPC with another length of 3.0 meters. Accordingly, for example, SHO-SM-LC/APC-SC/APC-15.0- single-mode duplex cord with LC-LC connectors and APC engraving, 15 meters long.

Some features

Optical modules are active equipment, they consume electricity and generate heat. This must be taken into account when connecting the equipment to the mains. Also, a switch filled to capacity with powerful modules may require additional cooling.Do not forget that lasers are built into the optical modules, and certain safety precautions must be observed with them. Of course, in most cases they do not pose any threat due to low power, but there have been cases when long-range powerful 10GE modules can completely burn out the retina or leave a burn if you use your finger as an attunator.

Modern optical modules have the function DDM (Digital Diagnostics Monitoring)- a number of sensors are built into them, through which you can determine the current value of some parameters. It looks through the interface of the equipment in which the module is installed. The most important parameters for you are the current received power and temperature.

A number of network equipment manufacturers prohibit the use of third-party modules in their equipment. At least before, Cisco did not allow them to run, they simply did not work in it. Now in narrow circles they are known

Flat connectors (Flat connectors). RS series connectors. RS series connectors. SPC series connectors (Super Physically Contact). Connectors of the UPC series. Connectors of the APC series. Connectors type FC. Adapter for FC with attenuator. FC connector with metal ferrule. Connectors type ST. Connectors type SC. Biconic. DIN. D4. E-2000. Connectors type LC. Connectors type MT-RJ. Connectors type VF-45. Connectors type MU. Perspectives for local networks.

Connectors for optics

Basic transmission parameters

Key Features optical connectors can be divided into the following groups: transmission parameters, long-term stability and resistance to environmental conditions.

The main transmission parameters of optical connectors are insertion loss and back reflection. These parameters depend mainly on such factors as the transverse displacement of the axes and the angle between them, as well as on the Fresnel reflection of the optical signal at the interface between two optical media.

Optical attenuation is of the greatest importance for assessing the losses introduced by a detachable connection. This parameter has a major impact on the amount of total losses in the optical path. The amount of optical attenuation mainly depends on the misalignment (lateral deflection) of the cores of the spliced optical fibers.

In addition to insertion attenuation, an important optical characteristic is the reverse reflection. The main source of the reflected signal is the interface between two media, for example, the material of an optical fiber and air. This component of losses can reach significant values. In addition, the back reflection is not constant over time. Under the influence of external influences, it can ultimately disrupt the stability of the system. Back reflection creates the most serious problems for narrow-band, high-coherence lasers (such as those used in DWDM systems and in equipment for cable television networks).

Due to the small number of detachable joints in the path, the requirements for the amount of losses introduced by them were somewhat reduced compared to the requirements for, for example, welded joints. This made it possible to significantly simplify the design and reduce the cost of products in which the positioning of the spliced fibers is limited by passive transverse alignment.

Termination technology

Manufacturers offer various termination technologies, that is, mounting connectors on optical fibers.

At a certain stage (which can now be considered initial), it was assumed that the technology for creating detachable connections would include technological operations for fixing the optical fibers to be connected in the workpiece plug using a chemical fixative. Epoxy glue or its analogues was used as a fixative. After fixing, the fiber had to be cleaved, and then the end of the connector with the protruding fiber had to be polished in a special way until the required end shapes were achieved.

In order to speed up the installation process, technologies have been developed without the use of epoxy glue. Such technologies use mechanical fixation of the fiber with clamps built into the connector, thermal fixation with hot melt adhesives, etc. However, over time, the popularity of such technologies has declined. Probably, the reasons for this were the cold flow of hot melt adhesives under pressure, as a result of which the optical fiber inside the connector shifted along the axis over time, and this entailed a deterioration or loss of physical contact, and, consequently, an increase in insertion loss and back reflections.

At present, connectors with a built-in piece of optical fiber in the buffer and secondary coatings are most widely used. This segment is joined to the fiber of the cable. Despite the fact that instead of one junction, two are obtained, this technology has proven itself in practice. Its main advantage is the absence of the technological operation of polishing the end of the connector during the termination of the fibers, which requires a lot of time, and for high-speed networks, also expensive equipment for grinding and control. These procedures are carried out in stationary conditions at the manufacturing plant. This approach allows the manufacturer to almost endlessly improve the quality of polishing the ends of the fibers being joined, use new technologies aimed at reducing losses and improving parameters. optical connectors, without forcing the buyer to purchase more and more advanced (and, of course, expensive) equipment for the final preparation of connectors for work.

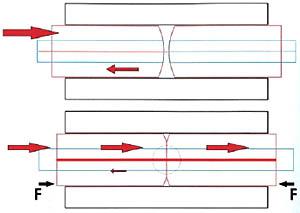

Ensuring Optical Contact

It is technologically difficult to obtain completely perpendicular ends with ideal contact surfaces in the process of fiber polishing. Minimization of the value of the reflected signal requires a guaranteed absence of an air gap between the cores of the spliced optical fibers. To achieve this, the ends of the joined fibers are polished in such a way as to obtain spherical surfaces. When joining, the longitudinal clamping of the fibers is set, which causes elastic deformation of the ends of the fibers and optical contact in the region of the cores of the fibers being joined, at which the air gap between them becomes minimal.

Flat connectors

One of the first solutions for the preparation of the end surfaces was polishing the end of the tip with the optical fiber fixed in it perpendicular to the fiber axis. In order to avoid direct contact of the fibers, which can lead to serious damage - scratches and chips - with this approach, a recess of about a few micrometers (2-3 microns) is realized. To improve performance, an immersion gel is sometimes used, the refractive index of which is close to the material of the optical fiber. The gel fills the gap between the tips.

PC series connectors

Method of preparation of end surfaces called "Physical Contact" (Physically Contact - PC) involves fixing the optical fiber in an aluminum tip. The end face is polished in a certain way in order to achieve full contact of the end surfaces. However, when the fiber is polished, negative changes occur in the surface end layer in the infrared range (the so-called "infrared layer"), due to mechanical changes during polishing. This factor limits the use of such connectors on high-speed networks (565 Mbps).

SPC (Super Physically Contact) Series Connectors

To improve the contact of the optical fiber, the core radius was narrowed to 20 mm, and softer zirconium was used as the tip material. This approach has reduced polishing defects such as bevels. The ability to bend zirconium at the submicron level allowed the fiber to contact even at bevels of hundreds of microns without significant deterioration in parameters. However, such polishing leaves the problem of the infrared layer unresolved.

UPC series connectors

The UPC (Ultra Physically Contact) end polishing technique is characterized by low stresses. Polishing is carried out under the control of complex and expensive control systems. As a result, the problem of the surface infrared layer is eliminated. Reflectivity is greatly improved and these connectors can be used in high-speed systems with a throughput of 2.5 Gbps and above.

APC Series Connectors

The most effective way to reduce the energy level of the reflected signal is the method of polishing the ends of optical fibers at an angle of 8-12° from the perpendicular to the fiber axis (Angled Physically Contact - APC). At such a junction, the reflected light signal propagates at an angle greater than the angle at which the signal is injected into the optical fiber.

APC connectors are distinguished by their color coded shank (usually green) as they cannot be used with connectors of a different finish.

It should be noted that some manufacturers interchange the names Super PC and Ultra PC, which should be taken into account in order to avoid inconsistencies in the connections with the design parameters. This is especially true for newly installed adapters and connectors on lines where products from other manufacturers are already in use.

In general, when connecting two connectors through an adapter, it is better to use connectors of the same series. When pairing connectors of different series (flat, super PC, ultra PC), the reflection coefficient of the mixed pair will be worse. The use of other series in conjunction with the APC series is generally unacceptable and may lead to the failure of one or both connectors.

Main types of connectors

FC type connectors

FC type connectors were developed by NTT and are mainly focused on applications in single-mode long-distance links, specialized systems and cable television networks. A ceramic tip with a diameter of 2.5 mm with a convex end surface with a diameter of 2 mm provides physical contact between the coupled light guides. The tip is manufactured to tight geometric tolerances to ensure low loss and low back reflections. The radius of the tip provides physical contact between the coupled fibers.

To fix the FC connector on the socket, a union nut with M8x0.75 thread is used. In this design, the spring-loaded tip is not rigidly connected to the body and shank, which complicates and increases the cost of the connector, but this addition pays off in increased reliability.

![]()

FC type connectors are resistant to vibrations and shocks, which allows them to be used on appropriate networks, for example, directly on mobile objects, as well as on structures located near railways.

ST type connectors

BT connectors were developed by AT&T in the mid-80s. The successful design of these connectors led to the appearance on the market of a large number of their analogues.

Currently, ST connectors are widely used in the optical subsystems of local networks.

A ceramic tip with a diameter of 2.5 mm, with a convex end surface with a diameter of 2 mm, provides physical contact between the coupled light guides. To protect the end of the fiber from damage during scrolling at the time of installation, a side key is used, which is included in the groove of the socket; the plug on the socket is fixed with a bayonet lock.

ST connectors are simple and reliable in operation, easy to install, relatively inexpensive. However, the simplicity of the design also has negative sides: these connectors are sensitive to sharp forces applied to the cable, as well as to significant vibration and shock loads, because the tip is a single unit with the body and shank. This drawback limits the use of this type of connectors on moving objects.

ST connector parts are usually made of nickel-plated zinc alloy, less commonly plastic.

When assembling the connectors, the aramid threads of the reinforcing braid of the cable are laid on the surface of the rear part of the case, after which the metal sleeve is pushed and crimped. This design greatly reduces the likelihood of fiber breakage when the connector is pulled out. To further increase the mechanical strength of the connecting cords in the connectors of a number of manufacturers, crimping is provided on the back of the case not only for aramid threads, but also for the outer sheath of the minicable.

The active use of ST connectors led to the search for ways to improve the quality of these products. Thus, as development progressed, SPS and UPS versions of this type of connectors appeared.

SC type connectors

One of the disadvantages of FC and ST type connectors is the need for a rotational movement when connecting to an adapter. To eliminate this disadvantage, which prevents an increase in the density of mounting on the front panel, SC type connectors have been developed. The body of the SC connector is rectangular in cross section. The tip is not rigidly connected to the body and shank.

The SC connector is connected and disconnected linearly (push-pull), which prevents the connector tips from turning relative to each other at the moment of fixation in the adapter. The locking mechanism opens only when the connector is pulled out by the housing. The disadvantages of SC connectors include a slightly higher price and lower mechanical strength compared to the previously considered connectors of the FC and ST types. The force pulling the SC connector out of the adapter is regulated within 40 N, while for the FC series this value can practically equal the strength of the mini cable. As in the case of ST connectors, this disadvantage limits the use of SC type connectors on moving objects.

Biconic

Biconic type connectors have become popular in the US thanks to the efforts of Lucent Technologies. The body of the connector is made of plastic and may contain a key that prevents the rotational movement of the core during screwing. The non-standard spring-loaded ceramic core is made in the form of a truncated cone, and at the base the diameter of the cone is almost equal to the inner diameter of the body. This design seems to be more reliable than its counterparts. However, studies have shown that this type of connectors loses in terms of temperature stability characteristics to connectors with a ferrule of a complex multilayer design. In addition, the non-standard core design made it difficult to use such connectors in hybrid connectors.

Currently, Biconic connectors have completely lost their positions to modern types of connectors with a standard core size.

DIN

Traditionally, products that meet this standard have been widely distributed in Germany and other European countries. The standard 2.5mm ceramic core protrudes far beyond the case. The plastic case is equipped with a key that prevents the core from rotating around its axis when screwed into the adapter.

DIN type connectors have found application in test equipment and telecommunications equipment.

D4

D4 connectors have also become widespread in Europe. The main features of their design are the key protruding beyond the metal case (non-technological design) and a non-standard ceramic core with a diameter of 2 mm. For fixing on the socket, the connectors are supplied with a union nut with M8x0.75 thread.

Despite these shortcomings, this type of connector was produced for quite a long time, and by the end of the 90s of the last century, PS-, SPS- and UPS-versions of such connectors were already being produced. The main manufacturers of D4 connectors are Western European companies, however, for the production of equipment supplied to European operators, the production of such connectors has also been established in the USA.

E-2000

E-2000 type connectors have one of the most complex designs. Connecting and disconnecting the connector is done linearly (push-pull). The locking mechanism opens only when the connector is pulled out by the body using a special key insert. It is practically impossible to accidentally turn off such a connector without using a key (that is, a load is required to destroy the latch of the connector housing).

The tip in connectors of the E-2000 type is made in the form of a multilayer ferrule with a diameter of 2.5 mm. Housings of connectors and adapters are made of durable polymer. The main innovation is plastic shutters that act as plugs when the adapter is disconnected. They also serve to prevent dust from entering the optical contact plane.

This type of connectors is distinguished by improved optical performance and stable temperature characteristics, as well as high reliability (at least 2 thousand on-off cycles are guaranteed). The housing section is square, which makes it easy to implement duplex connectors.

Among other things, it should be noted the indisputable advantage of this product - reducing the influence of the human factor. When turned on, the following are warned: the possibility of damage to the end surface of the optical fiber due to excessive efforts aimed at connecting two connectors; insufficient switching force; incorrect positioning, as well as flaws in the cleaning of optical contact surfaces.

The connector is designed and manufactured by Diamond with a focus on product quality. In addition to Western European countries, the production facilities of this company are also located in Eastern Europe. Despite the high optical performance and reliability of the design, the price factor still holds back the large-scale introduction of the E-2000.

The appearance of the E-2000 marked the beginning of a new stage in the creation of connectors for optical fibers - the development of SFF (Small Form Factor) connectors, which will be discussed later.

High Density Connectors

An analysis of the advantages and disadvantages of previously developed connectors showed the need to create new types of connectors. With the same operating parameters as their predecessors, they had to offer great space savings in order to increase the mounting density on the front panels.

The dimensions of the connector for metal current-carrying conductors of the RJ-45 type were taken as the basis for the dimensions of the adapters. This made it possible to use common design solutions for the installation of RJ-45 and optical connectors of the designs under development.

Leading manufacturers of passive optical components are involved in the development of new generation connectors. From the whole list of models, connectors such as LC, MT-RJ, VF-45n MU are most widely used. A number of manufacturers of passive optical components have already acquired licenses for the production of connectors of these types, and their sales volumes are constantly growing.

LC type connectors

The developer of LC-type connectors - the American company Lucent Technologies - is one of the leading manufacturers of telecommunications equipment, and therefore a "trendsetter" in the field of passive optics. This type of connector was originally (and, as it turned out, quite reasonably) the role of the leader in sales both in the United States and in Europe.

The design of the connector is relatively simple: a ceramic core with a diameter of 1.25 mm, not connected to a plastic case. Locking mechanism - latch (similar to RJ-45). Losses, according to the manufacturer, are about 0.2 dB. A pair of connectors can easily be combined into a duplex.

Connectors type MT-RJ

MT-RJ connectors are developed by a consortium of manufacturers including Amp Hewlett-Packard, Siecor LIN, Fujikura and USConnec. These connectors are manufactured exclusively as duplex pairs and therefore cannot be considered universal. Technologically, they are difficult to manufacture.

The connector housing contains a pair of metal guides in which two optical fibers are pre-installed. The optical fibers of the cable are welded to the pre-installed fibers. Once installed, the cable is secured by turning the locking key.

The average loss is about 0.2 dB.

MT-RJ type connectors are used in switches, hubs and routers by many leading equipment manufacturers.

Connectors type VF-45

3M Corporation also could not fail to respond to market trends regarding the introduction of SFF connectors. The company developed its own design - VF-45 duplex connector for single-mode and multimode fibers - and began to actively promote it on the market. It may also be marketed under the name SJ.

This connector is made using push-pull technology - the connection is made linearly. It should be noted that for the sake of ergonomics, the connector shank is inclined at an angle of approximately 45° from the fiber connection plane, that is, it is lowered down. At the same time, a high density of installation is ensured - a panel for mounting RG-45 is used. Instead of the ceramic ferrules used by most manufacturers, a V-groove is used, which makes the connector cheaper to manufacture.

The manufacturer guarantees the quality and stability of characteristics, based on more than a decade of experience in the operation of optical connectors made using this technology. The connector is equipped with a self-latching shutter to prevent dust from entering the optical contact surface.

The manufacturer guarantees high quality indicators: the attenuation level is not higher than 0.75 dB, and the return reflection is less than 26 dB.

Like MT-RJ connectors, VF-45 are designed for use in telecommunications equipment: switches, hubs, routers.

MU type connectors

Connectors of this type are developed by NTT and manufactured by a number of other companies. They are approximately half the analogue of SC. The locking mechanism due to downsizing in connectors of this type may be less reliable.

The tip and centralizer are ceramic, 1.25 mm in diameter. The body is made of plastic, parts - polymer and metal.

The share of equipment manufactured with MU type connectors is relatively small, but there are growth prospects, primarily due to a decrease in the share of use of earlier designed connectors in equipment.

It is assumed that new generation connectors will gradually take a leading position in the market, and then completely displace their predecessors, unless by this time more advanced connector designs have been developed that combine the advantages of the above models and, at the same time, surpass them in some ways. or factors (for example, price or reliability).

Perspectives for LANs

Today, the active use of single-mode optical fibers in the construction of local networks determines the need for the production of many connectors in both single-mode and multi-mode versions.

Further improvement of structured cable networks is possible using materials that are not currently used (for example, polyamide fibers as a transmission medium). This will determine the need to develop specialized passive optical components, which will make solutions for local networks a separate independent area. As a result, it will be impossible to use the currently existing designs of passive optical components (in this case, optical connectors) as universal ones. At the same time, the emergence of new design solutions can become a powerful impetus both for modifying existing ones and for creating specialized connectors of new types.

Another driver of connector improvements is the development of higher speed transmission system hardware. This will result in new requirements for passive optical components, which also necessitates the improvement of existing and the creation of new designs of optical connectors.

The growth in the number of operated ports, the speed and range of information transmission requires new approaches to organizing the connection of equipment ports and SCS. One approach is to use LC connectors, which are available in a variety of designs. However, not all of them are effective in conditions high density installation of passive and active ports.

LC connector

The optical interface type LC (Lucent Connector) is one of the most widely used plug-in connector types today. The connector was introduced to the market in 1996 by Lucent Technologies and has received recognition from experts due to a number of advantages that the user receives in real-life operating conditions of the final passive and active equipment, along with the use of SFP transceivers. Analysts estimate that over 60 million LC connectors have been installed worldwide to date. Currently, about 30 companies officially have a license to manufacture this type of interface.

Among the main advantages of the optical LC connector is the ability to place a duplex optical port on the same footprint as an RJ45 copper port (Figure 1), and the LC connector uses a similar latch mechanism.

In the original version, the optical LC socket had a footprint equal to the size of the hole for a copper socket, which allowed for the "reuse" of existing copper patch panels and their combination.

|

|

|

|

|

|

The limited space available in data center machine rooms and the overall increase in the number of pieces of active equipment per unit area of the room has led to the emergence of more efficient - in terms of size, power consumption and cooling - active equipment. In turn, this forced structured cabling manufacturers to adapt their solutions to accommodate more passive optical ports by introducing a new small-sized duplex LC receptacle (the so-called SC foot print type), the footprint of which matches the dimensions of a standard SC simplex receptacle (Fig. 2). ).

Density or comfort

The advent of the small-sized duplex LC receptacle has increased the density of installation due to the closer placement of ports on the optical patch panel. Today, up to 48 duplex LC sockets can be accommodated per standard height unit. From the point of view of data center infrastructure, this means, for example, the ability to significantly reduce the number of units used in a rack with active equipment, to make the switching field more compact. However, from an operational point of view, the issue of serviceability of connected optical LC connectors remains unresolved. It is here that most SCS manufacturers have not managed to make significant progress in terms of technology.

The ease of use of any plug-in connection generally means that you can get free access to the optical connector without affecting adjacent, already connected connectors. This problem is especially critical in high-density installations, which are typical today for central switching optical distribution frames, as well as when connecting a number of types of network switches or routers.

It's no secret that a few years ago, operations department specialists perceived the LC interface extremely negatively, referring to the fact that it is extremely small in comparison with the usual SC connector, that it is difficult to remove it from the socket (often SCS manufacturers even suggested using a special tool, facilitating this operation), which forms a “beard” of entangled patch cords, since the latches of the connectors cling to the cable all the time, complicating the process of removing the optical cord.

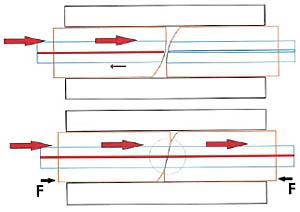

Since the density of connections in the case of LC is two or more times higher compared to other connectors (for example, SC), and the design of the latch of the LC connector and the copper RJ45 connector is implemented in a similar way, access to the latches is significantly limited when the cords are connected (Fig. 3a). I think most experts remember well the best tool for servicing duplex LC connections - ordinary tweezers.

Developers and manufacturers of optical LC connectors, taking into account this limitation, made design changes to the shape of the latch (Fig. 3, b). Various versions offered by different manufacturers suggest, for example, the creation of an additional platform for pressing the connector latch (the platform is part of either the connector housing or the duplex clip), increasing the usable working area of the latch, or complicating the geometry of its surface so that pressing the connector latch works more effective.

The presence of an additional platform simplifies access to the connector latches and reduces the tangling of optical cords. On the other hand, due to the deformation characteristics of the polymer material and the small dimensions of the latch, it is impossible to ensure uniform pressure on the latch in the duplex version of the LC connector. This usually causes the duplex connector to stick when unplugged, with one latch engaged and the other not. Along with additional time and effort, this can lead to the destruction of the connector housing due to asymmetrical side loading.

Among the interesting, non-standard solutions available on the market, it should be noted the design of the LC connector with the so-called inverted latch (Fig. 4). Keeping full compatibility with standard sockets, this connector design provides good access to the latches due to the increased area, reduces the likelihood of tangling optical cords due to the fact that the optical cord cable will catch on the latch. In addition, in the duplex design, due to the design of the used clip, the applied force is evenly distributed on both latches.

Flexible shanks

One of the alternative approaches that increase the serviceability of LC detachable connections in high-density installation conditions is the use of shortened flexible shanks (Fig. 5). Manufacturers offering these solutions report that optical ports are easily accessible and patch cords can be safely managed even in tight spaces between the equipment plane and the cabinet door.

Note, however, that the use of a shortened body of the connector and/or a flexible shank, however, does not solve the issue of ease of access to the latches of the connector itself.

Design LC-HD

From the point of view of the use of plug-in connections, it is of particular interest to be able to combine the high density of connections inherent in the LC interface with the option of fixing the push-pull interface of the SC. In this case, access to the connector latches, especially in duplex versions, is not required at all. Such a design is on the market today (Fig. 6) under the trade name LC-HD (subject of a valid patent), where the abbreviation HD stands for High Density.

The manufacturer, while maintaining full compatibility with standard LC sockets and SFP/SFP+ transceivers, has created a solution for organizing high-density connections both on patch panels and on cards/blades of active equipment. Its main feature is the use of a special clip, thanks to which there is no need for access to the connector latches at all.

The proposed design solution works equally effectively in cases of horizontal and vertical orientation of LC sockets or optical transceivers, for example, on the blades of a heavy multiport switch (Fig. 7).

By applying even and symmetrical force to the connector latches, the user can connect or disconnect the duplex connector from the switch port almost blindly - this is a typical situation, for example, when using blades with ultra-dense mounting of transceivers.

A little about prospects

And in conclusion, I would like to draw attention to a special type of optical duplex interface - mini-LC. This decision arose as a result of an attempt to increase the density of mounting transceivers on the switch blade. Its characteristic feature is the reduced distance between the geometric centers of the connectors - 5.25 mm instead of 6.25 mm for the standard version. Corresponding changes were made to the design of transceivers, which were called mini-SFP.

Apparently, the practical future of such a solution is not yet obvious, although a number of manufacturers of optical connectors have announced the availability for ordering mini-LC connectors and patch cords based on them. In any case, this solution cannot be adapted within the framework of a complete cabling system, since the requirement of compatibility and universality of cabling with respect to active equipment of various vendors in the data center computer room is not met.

In general, developers and manufacturers passive components are only at the very beginning of the journey, and, of course, new interesting engineering solutions will still be presented to the attention of the market.