How to make a power supply from electronic ballast. Power supply: what can be made from an energy-saving lamp

In this article you will find detailed description the process of manufacturing switching power supplies of different powers based on the electronic ballast of a compact fluorescent lamp.

You can make a switching power supply for 5...20 Watts in less than an hour. It will take several hours to make a 100-watt power supply.

Compact Fluorescent Lamps (CFLs) are now widely used. To reduce the size of the ballast choke, they use a high-frequency voltage converter circuit, which can significantly reduce the size of the choke.

If the electronic ballast fails, it can be easily repaired. But when the bulb itself fails, the light bulb is usually thrown away.

However, the electronic ballast of such a light bulb is an almost ready-made switching power supply unit (PSU). The only way the electronic ballast circuit differs from a real switching power supply is the absence of an isolation transformer and a rectifier, if necessary.

At the same time, modern radio amateurs experience great difficulty in finding power transformers to power their homemade products. Even if a transformer is found, its rewinding requires the use of a large amount of copper wire, and the weight and dimensions of products assembled on the basis of power transformers are not encouraging. But in the vast majority of cases, the power transformer can be replaced with a switching power supply. If you use ballast from faulty CFLs for these purposes, the savings will amount to a significant amount, especially if we are talking about transformers of 100 watts or more.

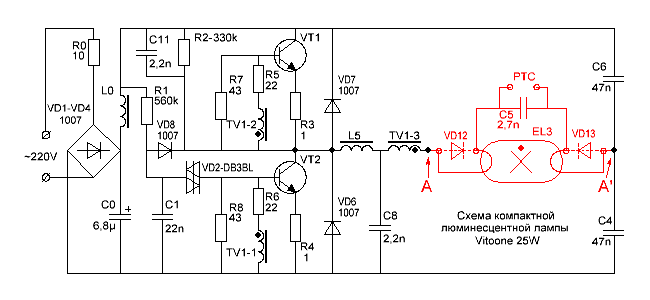

The difference between a CFL circuit and a pulse power supply

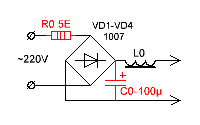

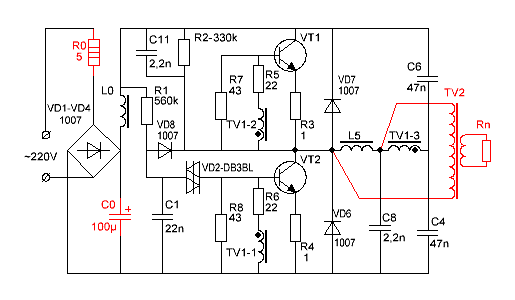

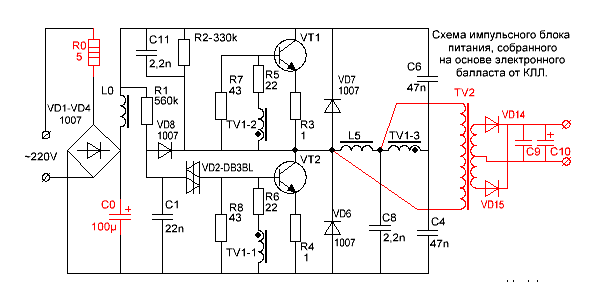

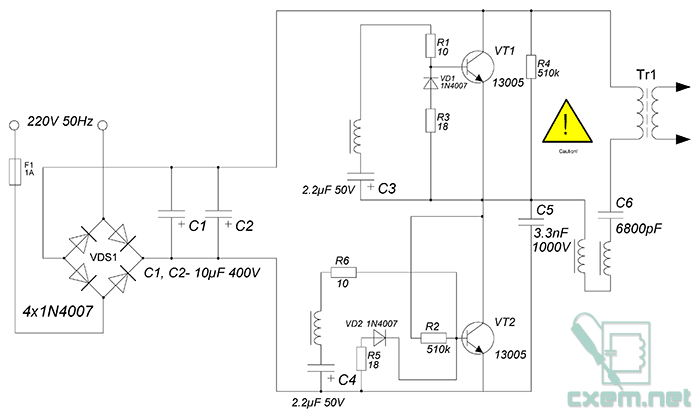

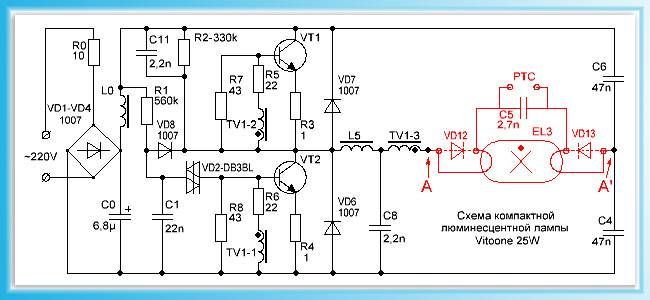

This is one of the most common electrical diagrams energy saving lamps. To convert a CFL circuit to pulse block power supply, it is enough to install just one jumper between points A – A’ and add a pulse transformer with a rectifier. Elements that can be deleted are marked in red.

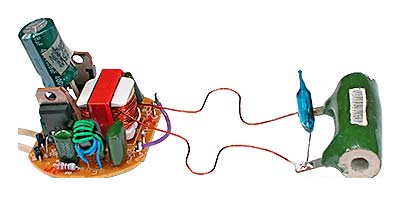

And this is a complete circuit of a switching power supply, assembled on the basis of a CFL using an additional pulse transformer.

To simplify, the fluorescent lamp and several parts were removed and replaced with a jumper.

As you can see, the CFL circuit does not require major changes. Additional elements introduced into the scheme are marked in red.

What power power supply can be made from CFLs?

The power of the power supply is limited by the overall power of the pulse transformer, the maximum permissible current of the key transistors and the size of the cooling radiator, if used.

A small power supply can be built by winding the secondary winding directly onto the frame of an existing inductor.

If the choke window does not allow winding the secondary winding or if it is necessary to build a power supply with a power significantly exceeding the power of the CFL, then an additional pulse transformer will be needed.

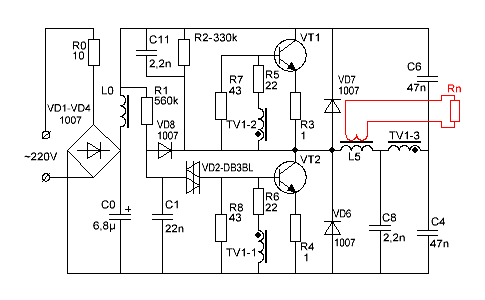

If you need to get a power supply with a power of over 100 Watts, and you are using a ballast from a 20-30 Watt lamp, then, most likely, you will have to make small changes to the electronic ballast circuit.

In particular, you may need to install more powerful diodes VD1-VD4 in the input bridge rectifier and rewind the input inductor L0 with a thicker wire. If the current gain of the transistors turns out to be insufficient, then you will have to increase the base current of the transistors by reducing the values of resistors R5, R6. In addition, you will have to increase the power of resistors in the base and emitter circuits.

If the generation frequency is not very high, then it may be necessary to increase the capacitance of the isolation capacitors C4, C6.

Pulse transformer for power supply

A feature of half-bridge switching power supplies with self-excitation is the ability to adapt to the parameters of the transformer used. And the fact that the feedback circuit will not pass through our homemade transformer completely simplifies the task of calculating the transformer and setting up the unit. Power supplies assembled according to these schemes forgive errors in calculations of up to 150% or more. Tested in practice.

Don't be scared! You can wind a pulse transformer within the course of watching one movie, or even faster if you are going to do this monotonous work with concentration.

Input filter capacitance and voltage ripple

In the input filters of electronic ballasts, to save space, small capacitors are used, on which the magnitude of voltage ripple with a frequency of 100 Hz depends.

To reduce the level of voltage ripple at the power supply output, you need to increase the capacitance of the input filter capacitor. It is advisable that for every watt of PSU power there is one microfarad or so. An increase in capacitance C0 will entail an increase in the peak current flowing through the rectifier diodes at the moment the power supply is turned on. To limit this current, a resistor R0 is needed. But, the power of the original CFL resistor is small for such currents and it should be replaced with a more powerful one.

If you need to build a compact power supply, you can use electrolytic capacitors, which are used in film flash lamps. For example, Kodak disposable cameras have miniature capacitors without identification marks, but their capacity is as much as 100µF at a voltage of 350 Volts.

A power supply with a power close to the power of the original CFL can be assembled without even winding a separate transformer. If the original inductor has enough free space in the magnetic circuit window, then you can wind a couple of dozen turns of wire and get, for example, a power supply for a charger or a small power amplifier.

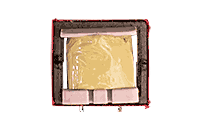

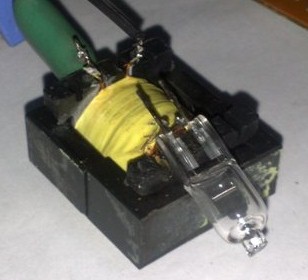

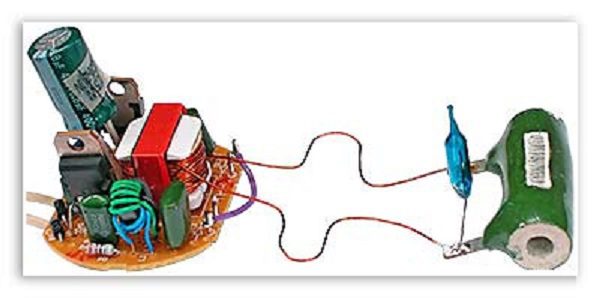

The picture shows that one layer of insulated wire was wound over the existing winding. I used MGTF wire (stranded wire in fluoroplastic insulation). However, in this way you can get a power of only a few watts, since most of the window will be occupied by the wire insulation, and the cross-section of the copper itself will be small.

If more power is required, then ordinary varnished copper winding wire can be used.

Attention! The original inductor winding is under mains voltage! When making the modification described above, be sure to take care of reliable inter-winding insulation, especially if the secondary winding is wound with ordinary varnished winding wire. Even if the primary winding is covered with a synthetic protective film, an additional paper gasket is necessary!

As you can see, the winding of the inductor is covered with a synthetic film, although often the winding of these chokes is not protected by anything at all.

We wrap two layers of electrical cardboard 0.05 mm thick or one layer 0.1 mm thick over the film. If there is no electrical cardboard, we use any paper of suitable thickness.

We wind the secondary winding of the future transformer on top of the insulating gasket. The wire cross-section should be selected as large as possible. The number of turns is selected experimentally, fortunately there will be few of them.

Thus, I managed to obtain power at a load of 20 Watts at a transformer temperature of 60ºC, and a transistor temperature of 42ºC. It was not possible to obtain even more power at a reasonable temperature of the transformer due to the too small area of the magnetic circuit window and the resulting wire cross-section.

The power supplied to the load is 20 watts.

The frequency of self-oscillations without load is 26 kHz.

Self-oscillation frequency at maximum load – 32 kHz

Transformer temperature – 60ºС

Transistor temperature – 42ºС

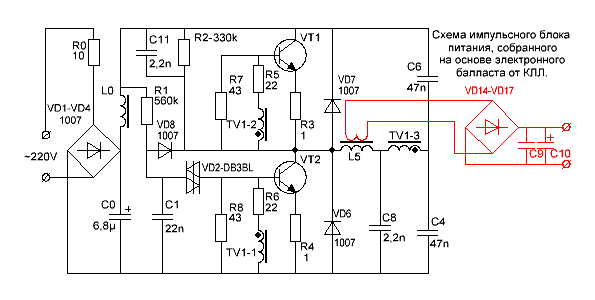

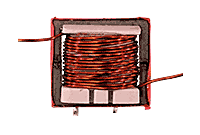

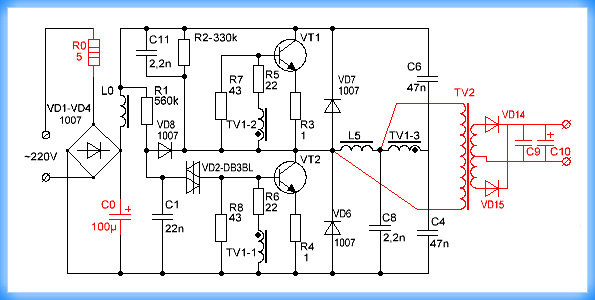

To increase the power of the power supply, we had to wind a TV2 pulse transformer. In addition, I increased the capacitance of the mains voltage filter capacitor C0 to 100µF.

Since the efficiency of the power supply is not 100%, we had to attach some radiators to the transistors.

After all, if the efficiency of the unit is even 90%, you will still have to dissipate 10 Watts of power.

I was unlucky; my electronic ballast was equipped with transistors 13003 pos. 1 of a design that was apparently designed to be attached to a radiator using shaped springs. These transistors do not need gaskets, since they are not equipped with a metal platform, but they also transfer heat much worse. I replaced them with transistors 13007 pos. 2 with holes so that they could be screwed to the radiators with ordinary screws. In addition, 13007 have several times higher maximum permissible currents.

If you wish, you can safely screw both transistors onto one radiator. I checked it works.

Only, the housings of both transistors must be insulated from the radiator housing, even if the radiator is located inside the electronic device housing.

It is convenient to fasten with M2.5 screws, onto which you must first put insulating washers and sections of an insulating tube (cambric). It is allowed to use heat-conducting paste KPT-8, since it does not conduct current.

Attention! Transistors are under mains voltage, so insulating gaskets must ensure electrical safety conditions!

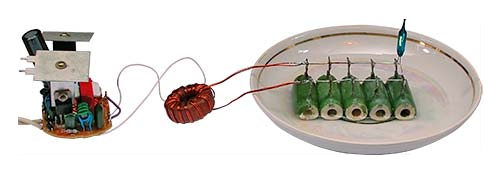

The load equivalent resistors are placed in water because their power is insufficient.

The power released at the load is 100 watts.

The frequency of self-oscillations at maximum load is 90 kHz.

The frequency of self-oscillations without load is 28.5 kHz.

Transistor temperature – 75ºC.

The area of the radiators of each transistor is 27 cm².

Throttle temperature TV1 – 45ºC.

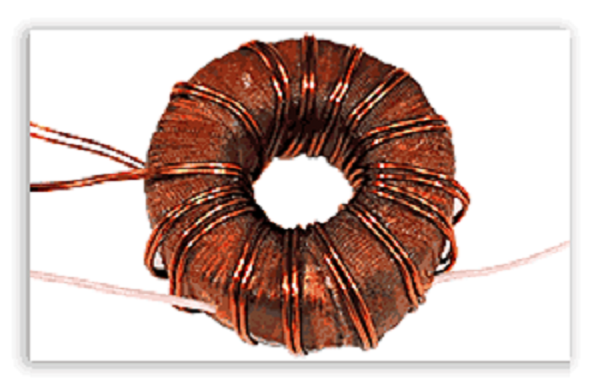

TV2 – 2000NM (Ø28 x Ø16 x 9mm)

Rectifier

All secondary rectifiers of a half-bridge switching power supply must be full-wave. If this condition is not met, the magnetic pipeline may become saturated.

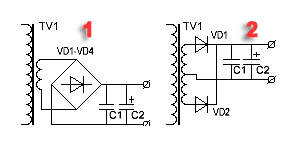

There are two widely used full-wave rectifier designs.

1. Bridge circuit.

2. Circuit with zero point.

The bridge circuit saves a meter of wire, but dissipates twice as much energy on the diodes.

The zero-point circuit is more economical, but requires two perfectly symmetrical secondary windings. Asymmetry in the number of turns or location can lead to saturation of the magnetic circuit.

However, it is precisely zero-point circuits that are used when it is necessary to obtain high currents at a low output voltage. Then, to further minimize losses, instead of conventional silicon diodes, Schottky diodes are used, on which the voltage drop is two to three times less.

Example.

Computer power supply rectifiers are designed according to a zero-point circuit. With a power delivered to the load of 100 Watts and a voltage of 5 Volts, even Schottky diodes can dissipate 8 Watts.

100 / 5 * 0.4 = 8(Watt)

If you use a bridge rectifier, and even ordinary diodes, then the power dissipated by the diodes can reach 32 Watts or even more.

100 / 5 * 0.8 * 2 = 32(Watt).

Pay attention to this when you design a power supply so that you don’t have to look for where half the power disappeared.

In low-voltage rectifiers it is better to use a circuit with a zero point. Moreover, with manual winding, you can simply wind the winding in two wires. In addition, high-power pulse diodes are not cheap.

How to properly connect a switching power supply to the network?

To set up switching power supplies, the following connection circuit is usually used. Here, an incandescent lamp is used as a ballast with a nonlinear characteristic and protects the UPS from failure in emergency situations. The lamp power is usually chosen close to the power of the switching power supply being tested.

When the switching power supply is operating at idle or at light load, the resistance of the lamp filament is small and it does not affect the operation of the unit. When, for some reason, the current of the key transistors increases, the lamp coil heats up and its resistance increases, which leads to the current being limited to a safe value.

This drawing shows a diagram of a stand for testing and setting up pulsed power supplies that meets electrical safety standards. The difference between this circuit and the previous one is that it is equipped with an isolation transformer, which provides galvanic isolation of the UPS under study from the lighting network. Switch SA2 allows you to block the lamp when the power supply supplies more power.

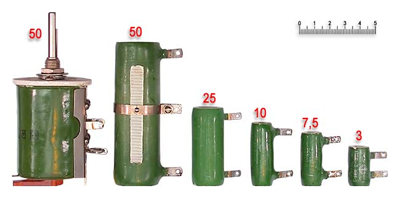

An important operation when testing a power supply is testing on an equivalent load. It is convenient to use powerful resistors such as PEV, PPB, PSB, etc. as a load. These “glass-ceramic” resistors are easy to find on the radio market by their green coloring. Red numbers are power dissipation.

It is known from experience that for some reason there is always not enough power equivalent to the load. The resistors listed above can, for a limited time, dissipate power two to three times higher than the rated power. When the power supply is turned on for a long time to check the thermal conditions, and the equivalent load power is insufficient, the resistors can simply be lowered into water.

Be careful, beware of burns!

Load resistors of this type can heat up to temperatures of several hundred degrees without any external manifestations!

That is, you will not notice any smoke or change in color and you can try to touch the resistor with your fingers.

How to set up a switching power supply?

Actually, a power supply assembled on the basis of a working electronic ballast does not require any special adjustment.

It needs to be connected to the load equivalent and make sure that the power supply is capable of delivering the calculated power.

During a run under maximum load, you need to monitor the dynamics of the temperature rise of the transistors and transformer. If the transformer heats up too much, then you need to either increase the cross-section of the wire, or increase the overall power of the magnetic circuit, or both.

If the transistors get very hot, you need to install them on radiators.

If a home-wound inductor from a CFL is used as a pulse transformer, and its temperature exceeds 60... 65ºС, then the load power must be reduced.

What is the purpose of the switching power supply circuit elements?

R0 – limits the peak current flowing through the rectifier diodes at the moment of switching on. In CFLs it also often serves as a fuse.

VD1… VD4 – bridge rectifier.

L0, C0 – power filter.

R1, C1, VD2, VD8 – converter starting circuit.

The launch node works as follows. Capacitor C1 is charged from the source through resistor R1. When the voltage on capacitor C1 reaches the breakdown voltage of dinistor VD2, the dinistor unlocks itself and unlocks transistor VT2, causing self-oscillations. After generation occurs, rectangular pulses are applied to the cathode of the diode VD8 and the negative potential reliably locks the dinistor VD2.

R2, C11, C8 – make it easier to start the converter.

R7, R8 – improve transistor blocking.

R5, R6 – limit the base current of the transistors.

R3, R4 – prevent saturation of transistors and act as fuses in case of breakdown of transistors.

VD7, VD6 – protect transistors from reverse voltage.

TV1 – feedback transformer.

L5 – ballast choke.

C4, C6 are decoupling capacitors on which the supply voltage is divided in half.

TV2 – pulse transformer.

VD14, VD15 – pulse diodes.

C9, C10 – filter capacitors.

In this article we will look at a simple version of a switching power supply. Ballast from LDS nowadays costs a penny, as does an electronic transformer (ET) from halogen lamps. We know about the main disadvantages of a UPS for halogen lamps - it is too unstable, the output voltage may deviate in one direction or another, and does not have a surge protector.

But all these disadvantages are nothing compared to the two main ones - with even a second short circuit at the output, the circuit literally explodes. Another main drawback is that the device only works under load, that is, if we connect an LED with a limiting resistor at the output, it will not light up, which makes this UPS very inconvenient for other purposes.

Ballast from LDS - compared to ET units, they are more stable; ballasts with surge protectors are also available. Even in cheap units we can see a choke, thermistor and electrolytes for power supply; a fuse is almost always installed in them. All this makes the ballast durable and reliable.

But let's remember that the ballast output voltage is only suitable for powering the LDS. In my case, a 40-watt LDS ballast was used.

I decided combine these two schemes to obtain a new type of UPS.

The Chinese 105-watt electronic transformer was disassembled, and the pulse transformer was soldered off the board.

There is no need to do any special modifications, just high voltage from the ballast it is supplied to the primary winding of the pulse transformer. Power is supplied through a 3kV 6800pF capacitor (both the capacitance and voltage of the capacitor can deviate in one direction or another by 30-40%)

On secondary winding transformer we get just 12 volts.

The power of such a power supply is small, but it is quite enough to create low-power laboratory UPSs. By adding a rectifier to the circuit, we get a UPS that can be used as Charger or a power supply for power amplifiers, the scope of application is quite wide, because without a power supply not a single design will work.

When supplementing with a diode rectifier, you need to use pulsed diodes, since the operating frequency of the device is 15-30 kHz or more (the frequency depends on the device circuit, its power and manufacturer, everyone is different).

Also, it should be taken into account that the output current can reach up to 3.5-4A, therefore, powerful diodes are needed. It is very convenient to use diode assemblies from computer power supplies; from a domestic interior, the KD213A is perfect.

List of radioelements

| Designation | Type | Denomination | Quantity | Note | Shop | My notepad |

|---|---|---|---|---|---|---|

| VT1, VT2 | Bipolar transistor | MJE13005 | 2 | Search in Chip and Dip | To notepad | |

| VD1, VD2 | Rectifier diode | 1N4007 | 2 | Search in Chip and Dip | To notepad | |

| VDS1 | Rectifier diode | 1N4007 | 4 | Search in Chip and Dip | To notepad | |

| C1, C2 | 10 µF 400V | 2 | Search in Chip and Dip | To notepad | ||

| C3, C4 | Electrolytic capacitor | 2.2 µF 50V | 2 | Search in Chip and Dip | To notepad | |

| C5 | Capacitor | 3.3 nF 1000V | 1 |

Small-sized power supply - from electronic ballast

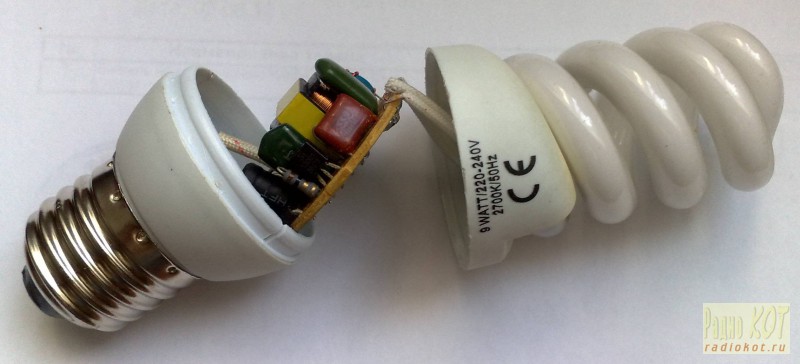

The article will focus on fluorescent lamps with a conventional threaded base, which appeared relatively recently, the so-called energy-saving lamps. If you find such a lamp that has expired or is faulty, the contents of its base will help solve a common problem - where to get a small-sized, economical and cheap mains power source. There have been many attempts to solve this problem - you can recall several publications on the pages of the Radio magazine under the general code name "Network Krona". The electronic unit of an energy-saving lamp contains most of the parts of such a power source; you just need to add an output circuit.

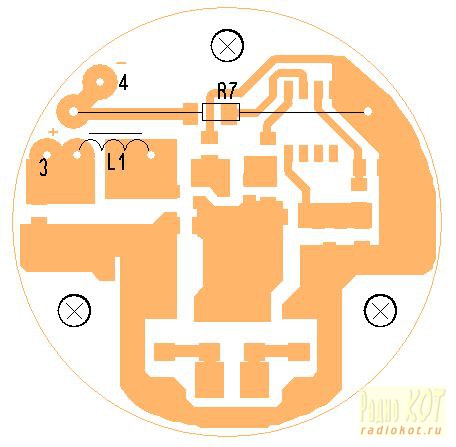

In the threaded base of the fluorescent lamp, which replaced the conventional incandescent lamp, there is a round printed circuit board on which the converter for powering it is assembled. The diagram of such a lamp is shown in Fig. 1. Among the features, we can note a specific output circuit with inductor L2, an autostart unit on a symmetrical dinistor VS1 and current control of the switching of power transistors. An autostart circuit is necessary because a current feedback generator does not start itself. Elements C1, R1 and L1 prevent radio interference that occurs during generator operation from spreading through the electrical network.

You should not be surprised at the variation in the values of the elements indicated in the diagram - it actually exists for lamps of different powers and from different manufacturers, of course, taking into account the fact that paired elements (for example, resistors R2 and R3) have the same ratings. The same applies to diodes with transistors - only the most common types are indicated in the diagram. The L2 inductor is assembled on a miniature W-shaped magnetic core made of ferrite with external dimensions of 10...15 mm, sometimes with a small gap. Its winding contains 240...350 turns of winding wire with a diameter of 0.2 mm.

Transformer T1 is made on a ring ferrite magnetic core with an outer diameter of 8...10 mm and a height of 3...5 mm, the primary winding (I) contains 6...10 turns, windings II and III - 2...3 turns each, Moreover, the wire can be either a winding wire with a diameter of 0.3...0.4 mm, or a regular mounting wire. Choke L1 - one and a half to two dozen turns of winding wire with a diameter of 0.5 mm, wound on a small ferrite rod. The operating frequency of the generator is determined mainly by the parameters of transformer T1 and at rated load is 40...60 kHz.

There is another converter option, most often used in the lowest-power lamps. Its diagram is shown in Fig. 2. The main difference from the previous option is the absence of an autostart circuit. The soft self-excitation mode is created here due to the opening of transistor VT2 by current through resistors R2 and R3. The launch is also facilitated by capacitor C5, which creates an additional pulse of the base current of transistor VT2 at the moment the power is turned on. In addition, low-power lamps usually do not have noise suppression circuits or even a fuse.

How to use such a product? There can be many options. The author, for example, using such a converter, managed to turn a Hitachi battery-powered electric razor into one powered by a 220 V network. For this, a board was used on which MPSA42 transistors are placed in TO-92 cases, and most of the other elements are surface-mounted. Basically, the device diagram corresponds to Fig. 1. The modification is shown in Fig. 3. First of all, it is necessary to remove the lamp leads, capacitor C5 and inductor L2 from the board, and also unsolder the leads of the primary winding of transformer T1.

Inductor L2 should be carefully disassembled and the old winding and gaskets creating a gap, if any, should be removed. It must be recalled that during disassembly it is very easy to break the W-shaped magnetic circuit. Therefore, if it is glued, even heating the ferrite may not help, and then I recommend immediately removing the frame with the winding, and then making a new one from cardboard. A magnetic core with a frame is used to manufacture transformer 12. The parameters of its windings are as follows: primary I - 400 turns of PEV-2 0.12 wire, secondary II (with an output voltage of 2 V) - 9+9 turns of PEV-2 0.6 wire. The secondary winding should be wound, as usual, with a wire folded in half, and do not forget about good inter-winding insulation (at least 2-3 layers of varnished cloth). The easiest way to assemble a T2 transformer is to use a strip of varnished cloth or even electrical tape stretched elastically along the outer contour of the halves of the magnetic circuit pressed against each other. It is not advisable to glue them together, but what if you need to take them apart again? You can try to wind the transformer without disassembling the magnetic circuit using a shuttle. The finished transformer is soldered into the board in its original place or positioned arbitrarily. Choke L3 is wound on any ferrite trimmer. Its winding contains 15...20 turns of PEV-2 wire with a diameter of 0.6...0.7 mm.

Changes in the primary circuit of transformer T1 are caused by the desire to move from current feedback, which is very sensitive to load, to output voltage feedback. The generator with voltage feedback is stable in operation, regardless of changes in the output current. If the generator does not start (possibly incorrect phasing), simply swap the ends of the primary winding of any transformer. Since the diodes of the output rectifier VD8, VD9 operate at a current close to the limit, it is advisable to install them on a duralumin plate of the largest possible area in the selected case for better cooling. The penultimate operation is the selection of the highest value of resistor R8, which ensures reliable startup of the converter at any load and the rated operating frequency (50...60 kHz). The resistance of resistor R8 is selected in the range from 1 to 30 Ohms. Finally, the output parameters of the resulting power source are measured, controlling the degree of heating of its elements. In the author's version, it was possible to obtain an output power of approximately 2...3 W (output voltage 2 V at a load current of 1...1.5 A).

All that remains is to mount the established source in the body of the powered device. The above-described unit was placed in the body of the electric razor in place of the AA battery and its charger.

A similar power supply can be made based on a converter assembled according to the circuit in Fig. 2. Recently, lamps with converters have appeared, the circuits of which differ from those shown in Fig. 1 and 2, - on field-effect transistors and even integrated circuits. They can also be used to create a power source - you just need to turn on the transformer T2 (Fig. 3) instead of the EL1 lamp, without removing or altering anything else. True, in this case, current feedback will remain, due to which such a converter can only operate normally with a constant load. If it is necessary to use the converter at maximum power, it is advisable to install the switching transistors on a suitable heat sink.

See other articles section.

The boom of fluorescent energy-saving lamps is gradually coming to an end. They have already been replaced by LED lamps, which have undeniable advantages: better efficiency, instant access to operating mode, long service life, they do not contain mercury vapor and do not emit ultraviolet radiation after the phosphor inside the bulb burns out. The only hitch is the still high cost of LED lamps. But if you have a failed fluorescent energy-saving lamp, then it can be easily converted into an LED lamp using the methods below.

First, a little preface.

Energy-saving lamps from ECOLIGHT, purchased several years ago, began to fail quite quickly. First, the filament in the bulb of one lamp burned out, but this malfunction was promptly corrected by installing a jumper on the printed circuit board parallel to the broken filament. The lamp lit perfectly even with the remaining intact filament. Then the second lamp suffered the same fate. After the repair, after working for about another six months, the remaining filaments burned out, first in one lamp, and a month later in the other. I no longer wanted to deal with fluorescent lamps, and the idea arose of converting the failed lamps into LED ones.

The first lamp had a power of 18 W and a fairly wide body with a diameter of 55 mm, which prompted the idea to install several dozen ultra-bright white LEDs with an operating current of 20 mA in it, connecting them to the network in series through a diode bridge, and using a capacitor as a damping ballast. The result is a circuit shown in the figure below:

A total of 40 HL-654H245WC ø4.8 mm LEDs with a brightness of 1.5 Cd and an angle of 140° were used. The circuit is assembled on two printed circuit boards made of single-sided foil fiberglass:

The boards are fastened together using one stand in the center. Here's what we ended up with:

Subjectively, the brightness of this lamp turned out to be approximately the same as that of a 30-watt incandescent lamp, and the power consumption was only 1.1 W:

![]()

The shade of the lamp turned out to be much cooler compared to an incandescent lamp.

What’s interesting is that commercially available LEDs of the same type and the same brightness, warm and cold, differ in price by 4 times, but even the warm LEDs used (more expensive) have a bluish tint compared to an incandescent lamp. As for the resulting cost of the manufactured LED lamp, then it turned out to be at the level of a ready-made purchased one with a similar number of LEDs. It is true that it is not known whether these ready-made 220 V lamps have a rectifier with a smoothing capacitor. Most likely not, because it is easier and cheaper to connect pairs of back-to-back LEDs in series and add a ballast capacitor. And let the lamp blink at twice the network frequency, because the Chinese manufacturer does not care about the consumer’s vision.

Considering the rather high cost of forty LEDs ($0.125 * 40 = $5), to remake a second 9 W lamp in a housing with a diameter of 38.5 mm

it was decided to use one powerful three-watt LED. The choice fell on EDEX-3LA1-E1 costing $1,875, which has the following characteristics:

color temperature.............................3200 K;

luminous flux (at a current of 700 mA)............... 130 lm;

illumination angle...............................................135°;

operating current........................................700 mA;

voltage........................................4 V.

Ready-made “STAR” radiators for these LEDs cost $0.156:

To obtain a current of up to 700mA to power such powerful LED it was decided to use an existing converter in the burnt-out fluorescent lamp. By closing all the terminals of the lamp bulb and winding an additional winding around the inductor on the board, such a converter can be converted into a power source at minimal cost. In fact, a ready-made electronic transformer is obtained from the lamp; it is only necessary to provide a stabilized current to power the LED.

Here is a diagram of an energy-saving lamp, copied directly from the board:

To convert it into an electronic transformer, it is enough to unsolder the flask, connect points 2 and 4 of the board to each other and wind an additional winding on inductor L2. A rectifier with a filter is connected to the additional winding.

To stabilize the current through the LED, the method proposed in was initially tested. Its essence lies in winding an additional winding on the control transformer T1 and shunting it with opening field-effect transistors to disrupt the oscillations of the converter when the output voltage (current) is exceeded. However, nothing good came of it. As the analysis of the operation of the above circuit showed, to restore the oscillations of the converter, a time of about 3 ms is required to charge the capacitor C3 to the breakdown voltage of the dinistor DB3 (30 V). Even with a very short-term bypass of the additional winding on T1, the time to restart the converter was about 3 ms. As a result, the adjustment characteristic of the converter is incomplete. When trying to only “slightly” reduce the output voltage, for example to 90...95%, at the output of the rectifier filter (from the additional power winding of the inductor), instead of a constant voltage, short positive pulses immediately appeared with relatively long dips of 3 ms. Those. control limits were possible only in the initial small area of the converter's operation.

Therefore, another circuit solution was used, shown in the figure below:

The additional circuit is a pulse current stabilizer, assembled without the use of specialized microcircuits on a widely used cheap element base. An additional winding is wound onto the lamp choke, the voltage from which is supplied to the diode bridge VD1...VD4 with filter capacitors C1, C3. The use of a bridge circuit is caused by the difficulty of winding twice as many turns on inductor L2 with a tap from the middle due to limited space.

The DA1 chip contains a +2.5 V voltage stabilizer to power the comparator DA2 and the resistive reference voltage driver R5, R6. Resistor R7 with a resistance of 0.1 Ohm acts as a current sensor. A power switch is assembled on transistors VT1, VT2. In the initial state, when power is applied, while current is not yet flowing through the HL1 LED, the output of the comparator DA2 is high, VT1 is closed and VT2 is open through R4. An increasing current flows through inductor L1 into the load. When the inverting input of comparator DA2 exceeds the reference voltage, the latter switches to a state with a low output level. VT1 opens sharply and shunts transition z-i VT2, closing the latter and causing a self-induction current in the circuit VD5, L1, C4, C5, HL1, R7. After the voltage at the inverting input of comparator DA2 decreases as C4, C5 discharge, the latter again goes into a state with a high output level. VT1 closes, VT2 opens and the whole process repeats again. The oscillation frequency at an input voltage of 7 V is 50...70 kHz. The measured efficiency of the switching current stabilizer was 86%.

The current through the LED is chosen to be 0.6 A for a more gentle operating mode and less heating.

Procedure for converting an energy-saving lamp

The lamp body is opened using a flat screwdriver (fastening with snaps). The upper part with the flask is carefully disposed of (Attention! There are mercury vapors in the flask! If the flask is damaged, it is necessary to treat the surrounding contacted objects with a solution of potassium permanganate). Capacitor C5 can be removed from the board, because he does not participate in the work. Points 2 and 4 on the board are short-circuited. The inductor L2 is unsoldered and an additional winding of 14 turns is wound with MGTF-0.1 wire (almost until the gap is completely filled). It is better to use MGTF for good galvanic isolation.

The throttle is soldered into place. It wouldn't hurt to check the C3 electrolyte with an ESR meter. If possible, it is better to replace it with a new one with a capacity of 4.7...10 µF x 400 V (105°C). This will reduce the 100 Hz ripple at the converter output.

After this, a board is made from one-sided foil fiberglass laminate:

For the manufacture of inductor L1, a ready-made DP2-0.1 at 100 μH was used. The standard winding was removed from it with a knife and a new one was wound with PEV2 ø0.3 mm wire evenly along the entire length of the core in 3 layers. The inductance of the inductor is 51 μH. You can also use a purchased inductor of suitable dimensions with an inductance of 47 μH and designed for a current of at least 1.5...2 A.

You can try replacing transistor VT2 IRLML6401 with IRLML6402.

Diodes VD1...VD4 SS14 can be replaced with any suitable SMD Schottky diodes rated for a current of at least 1A and a reverse voltage of 30...40V, for example SM5818, SM5819.

Diode VD5 SS24 (2A, 40V) can be replaced with SS22, 10BQ015 or similar.

As mentioned above, the LED is soldered onto a ready-made “STAR” radiator, which in turn is installed on a more massive radiator. In this case, a radiator from an old motherboard was used. With the mounting “ears” cut off, its dimensions are 37.5 x 37.5 x 6 mm. The radiator is attached to the additional board on 3 M3x15 racks. The board itself is attached to the top of the lamp housing with several turns of electrical tape. Between the standard and additional boards it is necessary to lay an insulating gasket cut, for example, from non-foil fiberglass.

It is advisable to first turn on the modified lamp with a load in the form of a 5-watt resistor with a resistance of 5...6 Ohms with an ammeter connected in series. It is safer to turn on a lamp for a 220 V network through a regular incandescent light bulb of 40…60 W. In normal operation, its spiral should not glow. The VD5 cathode must contain rectangular pulses with a frequency of 50...70 kHz. The voltage at C3 should be 5...8 V, the current through the load 0.6 A. More precisely, the current value can be set by selecting the resistance of resistor R5. After this you can connect the LED.

Subjectively, the brightness of the lamp modified in this way corresponds to a 30 W incandescent lamp. The shade is warm, but compared to an incandescent lamp it is a little cooler. The measured power consumption was 3.3 W:

The cost of the second version of the LED lamp was approximately 3.2 $.

Literature:

1) How to stabilize an electronic transformer. A.E. Shufotinsky. Radioamator No. 1/2010.

ID: 1371

|

What do you think of this article? |

Energy-saving lamps are widely used in everyday life and in production; over time they become unusable, but many of them can be restored after simple repairs. If the lamp itself fails, then from the electronic “stuffing” you can make quite a powerful block power supply to any desired voltage.

What does a power supply from an energy-saving lamp look like?

In everyday life, you often need a compact, but at the same time powerful low-voltage power supply; you can make one using a failed energy-saving lamp. In lamps, lamps most often fail, but the power supply remains in working order.

In order to make a power supply, you need to understand the operating principle of the electronics contained in an energy-saving lamp.

Advantages of switching power supplies

In recent years, there has been a clear tendency to move away from classic transformer power supplies to switching ones. This is due, first of all, to the major disadvantages of transformer power supplies, such as large mass, low overload capacity, and low efficiency.

The elimination of these shortcomings in switching power supplies, as well as the development of the element base, has made it possible to widely use these power units for devices with power from a few watts to many kilowatts.

Power supply diagram

The principle of operation of a switching power supply in an energy-saving lamp is exactly the same as in any other device, for example, in a computer or TV.

In general terms, the operation of a switching power supply can be described as follows:

- The alternating mains current is converted into direct current without changing its voltage, i.e. 220 V.

- A pulse-width converter using transistors converts constant pressure into rectangular pulses, with a frequency from 20 to 40 kHz (depending on the lamp model).

- This voltage is supplied to the lamp through the inductor.

Let's look at the circuit and operating procedure of a switching lamp power supply (figure below) in more detail.

Electronic ballast circuit for an energy-saving lamp

The mains voltage is supplied to the bridge rectifier (VD1-VD4) through a limiting resistor R 0 of small resistance, then the rectified voltage is smoothed on a high-voltage filter capacitor (C 0), and through a smoothing filter (L0) is supplied to the transistor converter.

The transistor converter starts at the moment when the voltage on capacitor C1 exceeds the opening threshold of dinistor VD2. This will start the generator on transistors VT1 and VT2, resulting in self-generation at a frequency of about 20 kHz.

Other circuit elements such as R2, C8 and C11 play a supporting role, making it easier to start the generator. Resistors R7 and R8 increase the closing speed of the transistors.

And resistors R5 and R6 serve as limiting ones in the base circuits of transistors, R3 and R4 protect them from saturation, and in the event of a breakdown they play the role of fuses.

Diodes VD7, VD6 are protective, although many transistors designed to work in such devices have such diodes built-in.

TV1 is a transformer, with its windings TV1-1 and TV1-2, the feedback voltage from the output of the generator is supplied to the base circuits of transistors, thereby creating conditions for the operation of the generator.

In the figure above, the parts that must be removed when remaking the block are highlighted in red; points A–A` must be connected with a jumper.

Modification of the block

Before you begin remaking the power supply, you should decide what current power you need to have at the output; the depth of the upgrade will depend on this. So, if a power of 20-30 W is required, then the alteration will be minimal and will not require much intervention in the existing circuit. If you need to get a power of 50 watts or more, then a more thorough upgrade will be required.

It should be kept in mind that the output of the power supply will be DC voltage, not AC. Get from such a power supply AC voltage frequency of 50 Hz is not possible.

Determining power

Power can be calculated using the formula:

P – power, W;

I – current strength, A;

U – voltage, V.

For example, let’s take a power supply with the following parameters: voltage – 12 V, current – 2 A, then the power will be:

Taking into account the overload, 24-26 W can be accepted, so the manufacture of such a unit will require minimal intervention in the circuit of a 25 W energy-saving lamp.

New parts

Adding new parts to the diagram

The added details are highlighted in red, these are:

- diode bridge VD14-VD17;

- two capacitors C 9, C 10;

- additional winding placed on ballast choke L5, the number of turns is selected experimentally.

The added winding to the inductor plays another important role as an isolation transformer, protecting against mains voltage reaching the output of the power supply.

To determine the required number of turns in the added winding, do the following:

- a temporary winding is wound onto the inductor, approximately 10 turns of any wire;

- connected to a load resistor with a power of at least 30 W and a resistance of approximately 5-6 Ohms;

- connect to the network, measure the voltage at the load resistance;

- divide the resulting value by the number of turns to find out how many volts there are per 1 turn;

- calculate the required number of turns for a permanent winding.

A more detailed calculation is given below.

Test activation of the converted power supply

After this, it is easy to calculate the required number of turns. To do this, the voltage that is planned to be obtained from this block is divided by the voltage of one turn, the number of turns is obtained, and approximately 5-10% is added to the result obtained in reserve.

W=U out /U vit, where

W – number of turns;

U out – required output voltage of the power supply;

U vit – voltage per turn.

Winding an additional winding on a standard inductor

The original inductor winding is under mains voltage! When winding an additional winding on top of it, it is necessary to provide inter-winding insulation, especially if a PEL type wire is wound, in enamel insulation. For interwinding insulation, you can use polytetrafluoroethylene tape to seal threaded connections, which is used by plumbers; its thickness is only 0.2 mm.

The power in such a block is limited by the overall power of the transformer used and the permissible current of the transistors.

High Power Power Supply

This will require a more complex upgrade:

- additional transformer on a ferrite ring;

- replacing transistors;

- installing transistors on radiators;

- increasing the capacity of some capacitors.

As a result of this modernization, a power supply with a power of up to 100 W is obtained, with an output voltage of 12 V. It is capable of providing a current of 8-9 amperes. This is enough to power, for example, a medium-power screwdriver.

The diagram of the upgraded power supply is shown in the figure below.

100W power supply

As can be seen in the diagram, resistor R0 has been replaced with a more powerful one (3-watt), its resistance has been reduced to 5 Ohms. It can be replaced with two 2-watt 10 ohm ones, connecting them in parallel. Further, C 0 - its capacity is increased to 100 μF, with an operating voltage of 350 V. If it is undesirable to increase the dimensions of the power supply, then you can find a miniature capacitor of such a capacity, in particular, you can take it from a point-and-shoot camera.

To ensure reliable operation of the unit, it is useful to slightly reduce the values of resistors R 5 and R 6, to 18–15 Ohms, and also increase the power of resistors R 7, R 8 and R 3, R 4. If the generation frequency turns out to be low, then the values of capacitors C 3 and C 4 – 68n should be increased.

The most difficult part may be making the transformer. For this purpose, ferrite rings of appropriate sizes and magnetic permeability are most often used in pulse blocks.

The calculation of such transformers is quite complicated, but there are many programs on the Internet with which this is very easy to do, for example, “Pulse transformer calculation program Lite-CalcIT”.

What does a pulse transformer look like?

The calculation carried out using this program gave the following results:

A ferrite ring is used for the core, its outer diameter is 40, its inner diameter is 22, and its thickness is 20 mm. The primary winding with PEL wire - 0.85 mm 2 has 63 turns, and the two secondary windings with the same wire have 12.

The secondary winding must be wound into two wires at once, and it is advisable to first slightly twist them together along the entire length, since these transformers are very sensitive to the asymmetry of the windings. If this condition is not met, then the diodes VD14 and VD15 will heat up unevenly, and this will further increase the asymmetry, which will ultimately damage them.

But such transformers easily forgive significant errors when calculating the number of turns, up to 30%.

Since this circuit was originally designed to work with a 20 W lamp, transistors 13003 were installed. In the figure below, position (1) is medium power transistors; they should be replaced with more powerful ones, for example, 13007, as in position (2). They may have to be installed on a metal plate (radiator) with an area of about 30 cm2.

Trial

A test run should be carried out with certain precautions taken so as not to damage the power supply:

- The first test run should be carried out using a 100 W incandescent lamp to limit the current to the power supply.

- Be sure to connect a 3-4 Ohm load resistor with a power of 50-60 W to the output.

- If everything went as expected, let it run for 5-10 minutes, turn it off and check the degree of heating of the transformer, transistors and rectifier diodes.

If no errors were made during the process of replacing parts, the power supply should work without problems.

If a trial run shows the unit is working, all that remains is to test it in full load mode. To do this, reduce the resistance of the load resistor to 1.2-2 Ohms and connect it directly to the network without a light bulb for 1-2 minutes. Then turn off and check the temperature of the transistors: if it exceeds 60 0 C, then they will have to be installed on radiators.

As a radiator, you can use either a factory radiator, which will be the most correct solution, or an aluminum plate with a thickness of at least 4 mm and an area of 30 sq. cm. It is necessary to place a mica gasket under the transistors; they must be secured to the radiator using screws with insulating bushings and washers.

Lamp block. Video

See the video below on how to make a switching power supply from an economy lamp.

You can make a switching power supply from the ballast of an energy-saving lamp yourself, with minimal skills in working with a soldering iron.